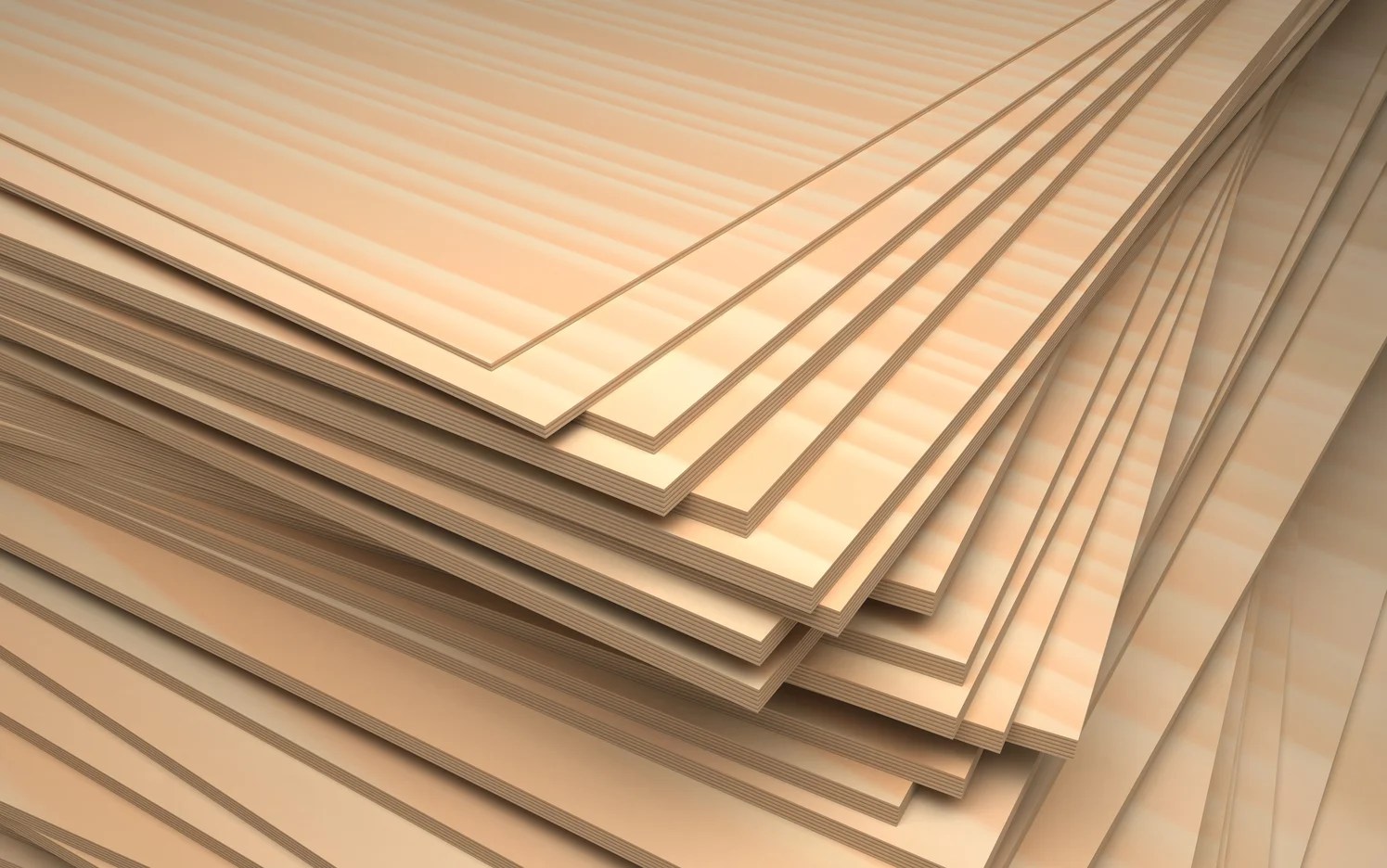

1/4″ plywood: it’s the workhorse for countless projects, from crafting to construction. This comprehensive guide dives deep into everything you need to know about this versatile material, whether you’re a seasoned pro or a weekend warrior. We’ll cover types, sizes, uses, working techniques, and even troubleshooting, so you can confidently tackle your next project.

Understanding 1/4″ Plywood Thickness

Before we get started, let’s clear up a common misconception: 1/4″ plywood isn’t always exactly 1/4″ thick. The label refers to the nominal thickness, not the actual thickness. Due to sanding and manufacturing processes, a 1/4″ sheet typically measures closer to 0.205 inches (about 5.2mm or 7/32″). This slightly thinner reality is standard across the industry and rarely impacts project outcomes, unless precise joinery is required. For demanding projects, using 11/32″ plywood might be a better fit for 1/4″ dadoes. Read more on the differences between 11/32″ vs. 1/4″ plywood.

Plywood Sizes and Custom Cuts

1/4″ plywood comes in various sizes to suit any project. The standard 4×8 foot sheet is readily available at most retailers like Home Depot and Lowe’s, perfect for larger applications like sheathing. Smaller sizes, such as 4×4 feet and 2×4 feet, are also common, offering manageability and reduced waste for smaller projects. Many retailers offer custom cuts, allowing you to get precise dimensions, which can be invaluable for specific projects.

Choosing the Right Wood Species

1/4″ plywood is available in various wood species, each with unique characteristics. For a versatile, budget-friendly option, pine is a great choice. Birch offers a smooth surface ideal for painting. Fir provides excellent strength and stability, making it suitable for structural applications where permitted by code. Maple adds a touch of elegance for finer projects. Cedar, naturally resistant to rot and insects, is perfect for outdoor use.

Decoding Plywood Grades

Plywood grades indicate the quality of the veneer, affecting the appearance and suitability for different applications. “BC sanded” plywood offers a smooth face ideal for painting or staining. Other grades might have knots, voids, or imperfections, perfectly acceptable for projects where the plywood won’t be visible, like underlayment.

Where to Buy 1/4″ Plywood

| Retailer | Price Range | Availability | Custom Cuts? |

|---|---|---|---|

| Home Depot | Varies by wood type and size | Generally good stock | Yes |

| Lowe’s | Varies by wood type and size | Generally good stock | Yes |

| Local Lumberyard | May offer specialty options | Can be limited | Often Yes |

| Online Retailers | May offer wider selection/delivery | Check shipping costs! | Varies |

Remember to compare pricing and availability before purchasing. Consider delivery costs, especially for larger sheets.

A Multitude of Uses

1/4″ plywood’s versatility makes it suitable for a wide array of applications:

- Underlayment: Provides a smooth, stable base for flooring.

- Sheathing: Offers structural support for walls (where code permits).

- DIY Projects: Perfect for shelves, boxes, and small crafts.

- Furniture: Commonly used for cabinet backs and drawer bottoms.

- Hobbies: Ideal for model making, crafts, and other creative projects. For a deep dive into project ideas, check out What is 1/4 Plywood Good For?

Working with 1/4″ Plywood: Tips and Tricks

Due to its thinness, working with 1/4″ plywood requires a bit of finesse. Use a sharp, fine-toothed blade for clean cuts, whether you’re using a circular saw, table saw, or jigsaw. A zero-clearance insert on a table saw is highly recommended to prevent the thin sheet from getting caught. For intricate shapes, a jigsaw or scroll saw offers excellent control. Secure the plywood firmly during cutting to prevent shifting and ensure accuracy. If using fasteners, consider the appropriate size, such as 10d nails for lighter applications or 16d nails for heavier construction.

Cutting Guide:

- Measure and Mark: Precise measurements are crucial.

- Secure: Use clamps or weights to hold the plywood firmly.

- Sharp Blade: A sharp, fine-toothed blade minimizes splintering.

- Steady Cuts: Avoid forcing the saw; let the blade do the work. Apply painter’s tape to minimize splintering.

Troubleshooting: Warping and Delamination

Warping and delamination are common issues with 1/4″ plywood. Proper storage is key to prevention: store it flat in a dry environment, supported across its entire surface. Minor warping might be corrected by clamping the sheet flat. Delamination can sometimes be repaired with wood glue.

Sustainable Choices

For eco-conscious projects, seek out FSC-certified plywood, indicating wood from responsibly managed forests.

Advanced Techniques: Bending Plywood

Bending 1/4″ plywood is achievable using techniques like kerf bending (shallow cuts on one side) for gentle curves or steam bending for more dramatic curves. Always test your bending technique on scrap pieces first.

Conclusion: Your 1/4″ Plywood Journey

This guide equips you with the knowledge to confidently choose and use 1/4″ plywood for your projects. Remember to consider your specific needs, choose the right materials, and employ the proper techniques. Happy woodworking!

- How to Remove Water Stains from Fabric: A Complete Guide - April 26, 2025

- How to Get Motor Oil Out of Clothes: Proven Methods & Expert Tips - April 26, 2025

- How to Get Deodorant Out of Black Shirts: Easy Stain Removal Guide - April 26, 2025