Planning a major power upgrade? Discover the perfect solution for your high-amperage needs by exploring our selection of 50 amp extension cord and learn about the crucial considerations for proper wiring with our guide on 60 amp wire size. Figuring out the right wire size is paramount, especially for a 150-amp circuit. This guide provides comprehensive information about selecting the correct 150-amp wire, covering applications, safety considerations, code compliance, wire types, voltage drop calculations, and comparisons to other wire sizes.

Understanding 150-Amp Wire

Wiring for 150 amps is a critical decision impacting your electrical system’s safety and efficiency. Choosing the wrong size can lead to inefficiencies, overheating, and even fire hazards.

Choosing Your Conductor: Copper vs. Aluminum

Your first decision involves selecting the conductor material: copper or aluminum. Copper offers superior conductivity, allowing for a smaller gauge wire, but comes at a premium. Aluminum is more budget-friendly but requires a larger gauge due to its lower conductivity. It also necessitates special connectors and anti-oxidant paste to prevent corrosion.

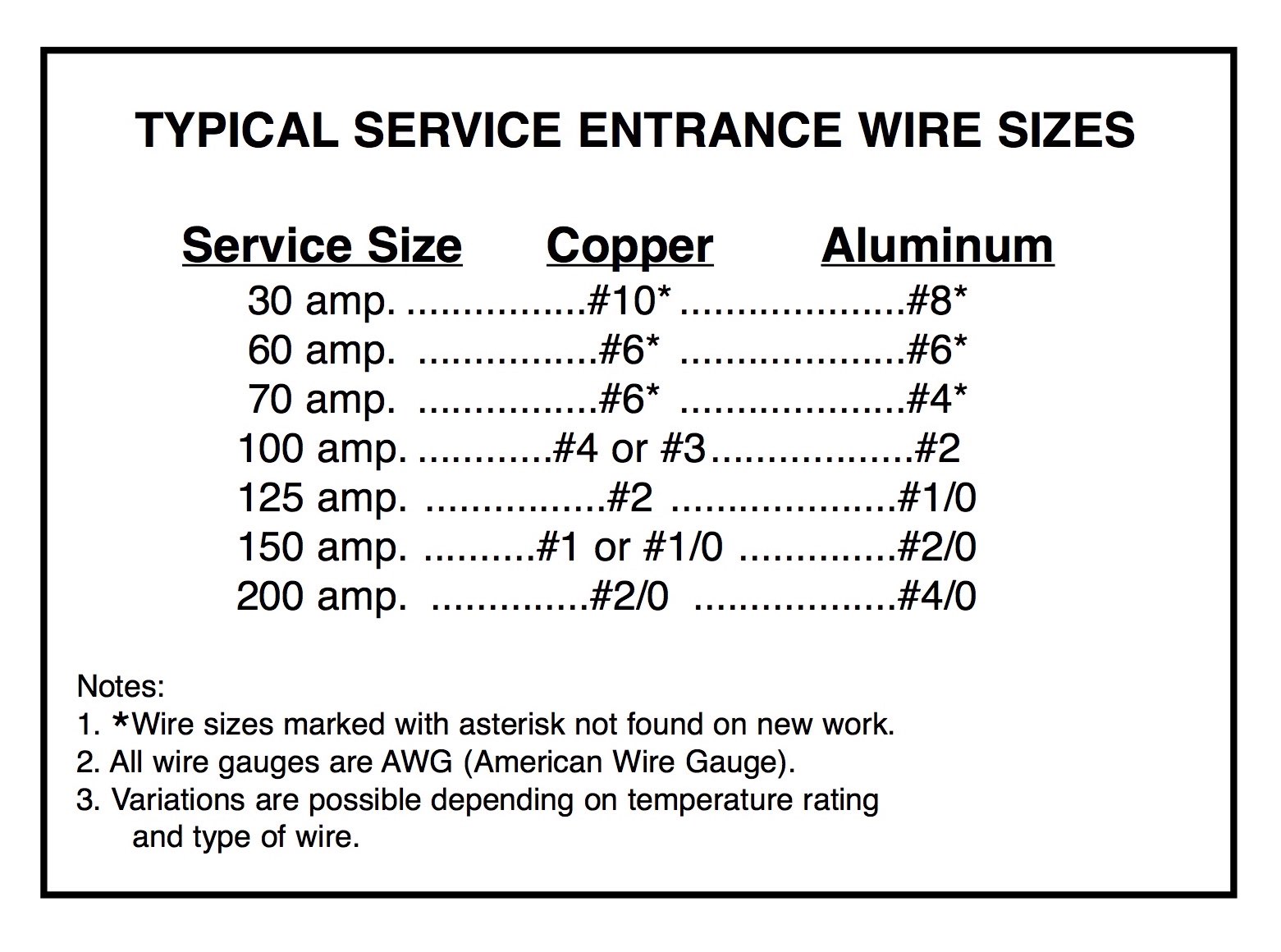

For a typical 150-amp setup, common recommendations are:

- Copper: 1/0 AWG

- Aluminum/Copper-Clad Aluminum: 2/0 AWG

Copper-clad aluminum attempts to balance cost and conductivity, offering a potential middle ground.

Wire Length and Voltage Drop

The length of your wire run significantly impacts wire size selection. Longer runs introduce voltage drop—the reduction in voltage as electricity travels through the wire. For runs exceeding 50 feet, increasing the wire gauge (e.g., using 2 AWG copper for a 150-amp circuit) may be necessary to compensate.

Essential Grounding

Proper grounding is non-negotiable for electrical safety. The NEC suggests the following grounding electrode conductor sizes for 150-amp systems:

- Copper: 6 AWG

- Aluminum: 4 AWG

Temperature, Load, and the 83% Rule

Ambient temperature and expected load influence wire choice. Higher temperatures reduce a wire’s ampacity (current-carrying capacity). Continuous loads (3+ hours) should be wired for 125% of the expected load (NEC 310.12), providing a safety margin.

Cost Analysis: Beyond the Initial Price

Copper’s higher upfront cost can yield long-term savings due to lower energy loss. Aluminum’s initial affordability might be offset by a larger gauge requirement and specialized connectors. Factor in both material and labor costs for a complete picture.

| Material | Wire Gauge | Cost (Estimate) | Conductivity | Notes |

|---|---|---|---|---|

| Copper | 1/0 AWG | Higher | Excellent | Easier to work with, smaller diameter |

| Aluminum/Copper-Clad Aluminum | 2/0 AWG | Lower | Good | Requires special connectors and anti-oxidant paste to prevent corrosion |

Professional Expertise: When to Call an Electrician

Working with 150-amp wiring is often best left to professionals. Their expertise ensures a safe, code-compliant installation and helps navigate the complexities of wire selection.

Planning for the Future: Oversizing for Expandability

Consider slightly oversizing your wiring to accommodate future electrical needs, avoiding costly rewiring later.

What Size Wire Is Rated for 150 Amps?

Selecting the correct wire for 150 amps depends on several factors, including material, run length, and local electrical codes.

Wire Selection Factors

The “right” wire size for 150 amps isn’t one-size-fits-all. Factors like material, run length, and even local codes come into play.

Material Matters: Copper, Aluminum, and Copper-Clad

Copper allows for a smaller gauge, while aluminum requires a larger one for the same amperage. Copper-clad aluminum seeks to balance cost and conductivity. Comparing copper versus aluminum often reveals that aluminum needs a thicker gauge. Current research suggests proper wire selection minimizes energy loss.

Understanding AWG

American Wire Gauge (AWG) measures wire thickness. Smaller AWG numbers indicate thicker wires. For most 150-amp residential projects under 50 feet, 1/0 AWG copper or 2/0 AWG aluminum is common. Longer runs necessitate thicker wires. Research continues to examine wire materials and insulation effects on voltage drop over long distances.

Distance and Voltage Drop

Long wire runs increase resistance, leading to voltage drop. For runs over 50 feet, 2 AWG copper is often recommended. On-going research explores how various materials impact this.

Grounding for Safety

Grounding is a critical safety feature. For 150-amp circuits, 6 AWG copper or 4 AWG aluminum grounding wire is typical.

NEC Compliance

The National Electrical Code (NEC) provides crucial safety regulations for wiring. Always consult the latest version for your area.

Voltage Drop Calculation

Use an online voltage drop calculator to determine the precise wire size needed for your run length and power requirements.

| Wire Material | AWG | Typical Run (feet) | Notes |

|---|---|---|---|

| Copper | 1/0 | Under 50 | Most common for shorter runs |

| Aluminum | 2/0 | Under 50 | Budget-friendly, but needs larger size |

| Copper | 2 | Over 50 | Best for longer distances to minimize voltage drop |

| Copper-Clad Aluminum | 2/0 | Under 50 | Balances cost and conductivity |

Key Considerations

Several factors influence optimal 150-amp wire selection: wire material, run length, NEC compliance, grounding, and voltage drop calculation. Consult a qualified electrician for specific advice and a safe installation.

What Wire Do I Need for a 150 Amp Sub Panel?

Choosing the right wire for a 150-amp subpanel involves balancing amperage, run length, and material.

Wire Sizing Factors

Wire size selection for a 150-amp subpanel depends on amperage, distance, and material, much like choosing a garden hose based on water demand and distance. For most setups under 50 feet, 1/0 AWG copper or 2/0 AWG aluminum/copper-clad aluminum is recommended.

Distance and Voltage Drop

Longer runs necessitate thicker wires to minimize voltage drop. Keeping voltage drop below 3% is generally recommended. Online calculators can help determine the correct wire size, including specialized calculators for 150-amp subpanels. Research suggests voltage drop is an area of continuing study.

Wire Material Options

- Copper: The most conductive option, allowing for smaller gauges, although more expensive.

- Aluminum: A budget-friendly alternative, requiring larger gauges.

- Copper-Clad Aluminum: A balanced option, offering decent conductivity at a moderate price.

Conduit: Protecting Your Wires

Conduit provides essential protection for your wiring. Choosing the correct conduit size and material is crucial for safety and code compliance.

Codes and Safety

Adhering to local electrical codes is essential. Undersized wire poses a significant fire hazard. Professional consultation is recommended for complex installations or safety concerns.

Recap

- For subpanel runs under 50 feet, 1/0 AWG copper or 2/0 AWG aluminum/copper-clad aluminum is typical.

- Longer runs require thicker gauge wires.

- Always follow local electrical codes.

- Conduit provides crucial wire protection.

- Consult a professional when in doubt.

This information is for general knowledge and should not substitute professional electrical advice.

What Size Conduit for 150 Amp Service?

Upgrading to 150-amp service requires careful selection of both wire and conduit.

Choosing the Right Wire: Copper vs. Aluminum

Copper offers superior conductivity, often preferred but comes at a higher cost. Aluminum requires thicker gauges for the sake amperage but is budget-friendly. For a 150-amp service, 1/0 AWG copper or 2/0 AWG aluminum is typical.

For runs over 50 feet, 2 AWG copper or larger is a good starting point to mitigate voltage drop.

Conduit Sizing

The NEC mandates a minimum 1-1/4 inch conduit for 150-amp services, ensuring adequate space and heat dissipation. Larger conduit can accommodate future expansion. Several conduit materials (PVC, EMT, rigid metal) exist, each with pros and cons. The optimal choice depends on your specific circumstances and local codes.

Grounding Is Key

Grounding is vital for electrical safety. 6 AWG copper or 4 AWG aluminum is recommended for grounding electrode conductors in 150-amp systems.

Voltage Drop: A Factor to Consider

Voltage drop impacts electrical efficiency. Using a voltage drop calculator is crucial to determine the appropriate wire size, taking wire length, load, and other factors into account.

Key Takeaways for Your 150-Amp Service

- Standard runs under 50 feet: 1/0 AWG copper or 2/0 AWG aluminum.

- Longer runs (50+ feet): 2 AWG copper or larger.

- Conduit: Minimum 1-1/4 inches.

- Grounding: 6 AWG copper or 4 AWG aluminum.

- Consult the NEC and local codes.

- Use a voltage drop calculator.

Always consult a qualified electrician for major electrical projects to ensure safety and code compliance.

- Ceramic Kitchen Wall Tiles: Style and Protection for Your Walls - December 17, 2025

- Kitchen tiling wall: Elevate your kitchen with stylish wall tiles - December 16, 2025

- Gray Kitchen Backsplash Tile: Ideas for a Stylish Upgrade - December 14, 2025