Okay, so you’re tackling a project and keep hearing about “16d nails.” Does that “d” make you think of pirate treasure? Don’t worry, it’s not that complicated. This guide is your cheat sheet to understanding 16d nails—the heavy lifters of the fastener world. We’ll decode the “d,” explore their best uses, and even cover how to hammer one in without bending it (because we’ve all been there). Whether you’re a DIY newbie or a seasoned pro, this guide has you covered. Let’s get nailing!

Decoding the “d” and Nail Dimensions

What’s in a “d”? Quite a bit of history, actually. That “d” stands for “penny,” a term originating from 15th-century England where 100 nails were sold for a certain number of pennies. A 16d nail, therefore, likely cost 16 pennies per hundred. Today, the “d” represents the nail’s length, with a 16d nail measuring a substantial 3-1/2 inches long. But length isn’t everything. The nail’s thickness, or gauge, plays a crucial role, too. Gauge is like wire sizes—the lower the number, the thicker the nail. A thicker nail generally offers more holding power, increasing the risk of splitting the wood. The ideal choice depends on the wood type and application.

Nail Sizes and the Penny System

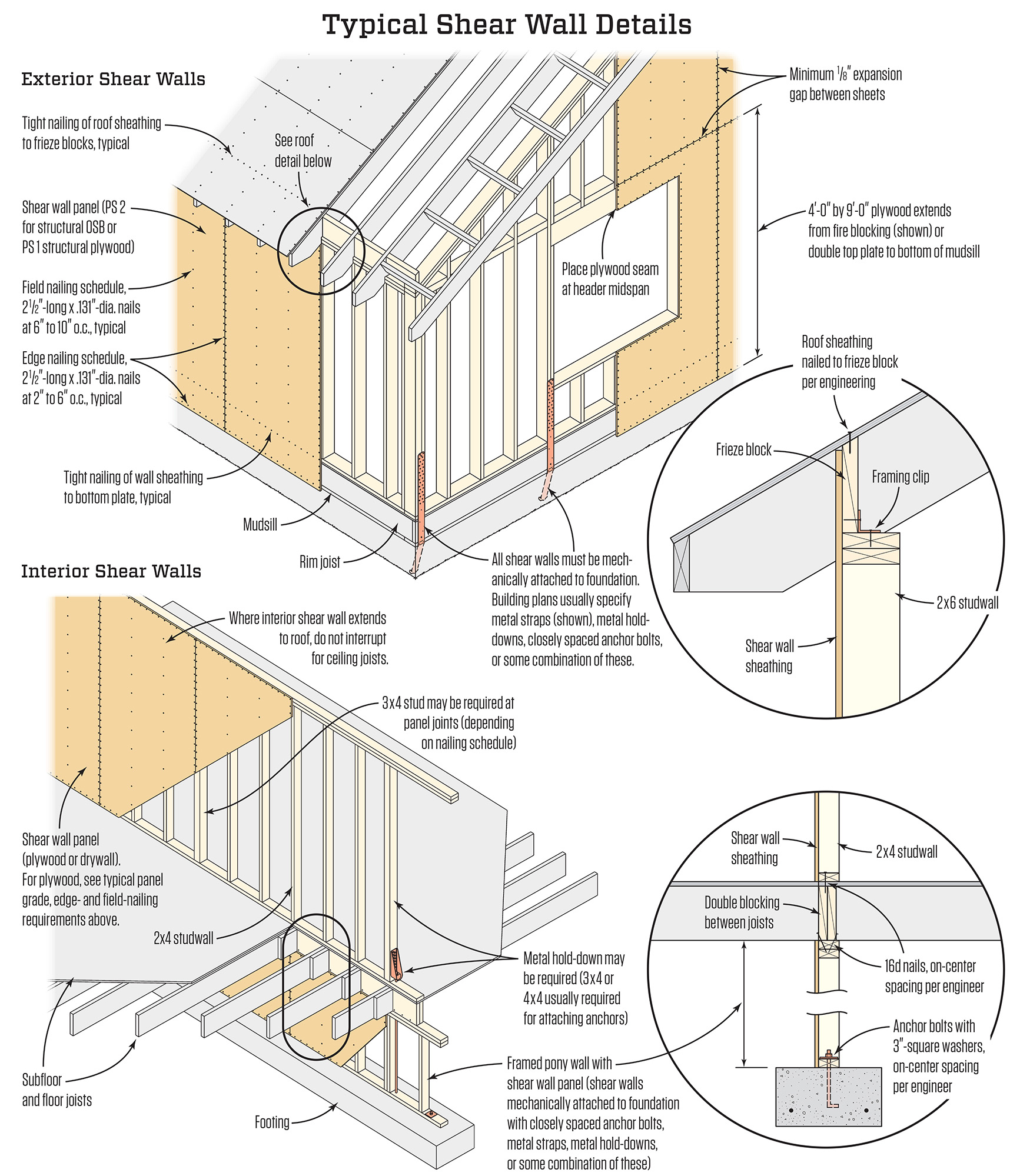

The penny system for nail sizing can be a little perplexing. While each “d” increment up to 16d typically signifies a 1/4-inch increase in length, this pattern becomes less predictable beyond 16d. A 20d nail, for instance, measures 4 inches–a full half-inch longer than a 16d nail. The following chart illustrates the relationship between penny size and length:

| Penny Size (d) | Length (inches) | Diameter (inches) | Gauge |

|---|---|---|---|

| 2d | 1 | 0.072 | 15 |

| 4d | 1-1/2 | 0.080 | 14 |

| 6d | 2 | 0.092 | 12.5 |

| 8d | 2-1/2 | 0.106 | 11.5 |

| 10d | 3 | 0.148 | 8 |

| 12d | 3-1/4 | 0.148 | 9 |

| 16d | 3-1/2 | 0.162 | 8 |

| 20d | 4 | 0.192 | 6 |

| 30d | 4-1/2 | 0.207 | 5 |

| 40d | 5 | 0.225 | 4 |

Discover the versatile applications of 1/4 plywood in your next woodworking project. Secure your projects with the strength and reliability of 10d nails.

Choosing the Right 16d Nail

Not all 16d nails are created equal. You’ll find variations designed for specific purposes:

-

Common Nails: The workhorses for general construction, these 16d nails are cost-effective but prone to rust.

-

Sinker Nails: Sporting a textured or coated head, sinker nails offer improved driving power and grip, much like all-terrain tires for your hammer.

-

Short 16d Nails: Shorter and thinner than standard 16d nails, these are less suitable for demanding framing where maximum holding power is essential.

Matching Nails to Materials and Projects

Just as you wouldn’t use a butter knife to cut a steak, choosing the right nail is crucial. For outdoor projects like decks and fences, galvanized or stainless steel 16d nails are essential to combat moisture and prevent rust. For interior framing with dry lumber, standard 16d common nails are usually sufficient. Wood type also matters. Hardwoods are more susceptible to splitting, so pre-drilling pilot holes might be necessary.

Exploring Alternatives to 16d Nails

While 16d nails excel in framing, other options may be more appropriate:

-

Screws: Offering superior holding power and pull-out resistance, screws are especially useful when dealing with pulling forces or potential warping. #9 or #10 construction screws, such as GRK R4 screws, are common alternatives for demanding applications.

-

Ringshank Nails: Providing a compromise between standard nails and screws, ringshank nails have rings on their shanks that enhance grip and holding power.

-

Adhesives: Construction adhesive, combined with nails or screws, can further reinforce strength and stability, and even prevent squeaking.

Prioritizing Safety

Working with nails requires safety precautions: Always wear safety glasses to protect your eyes from flying debris and handle nails with care. Keep them out of reach of children and pets.

Mastering Driving Techniques

Driving 16d nails effectively involves proper technique:

-

Choosing the Right Hammer: A heavier hammer, like a framing hammer, provides the necessary force for driving 16d nails without excessive effort.

-

Starting with a Solid Stance: Ensure good balance and stability to avoid mishaps.

-

Placing the Nail: Position the nail firmly against the material and tap lightly to set it.

-

Driving the Nail Straight: Use smooth, controlled swings, keeping the hammer face flush with the nail head.

-

Avoiding Bending: If the nail starts to bend, use the hammer’s claw to remove it and start again with a new nail and a pre-drilled pilot hole.

-

Setting the Head (Countersinking): Use a nail set to drive the nail head slightly below the surface, allowing for a clean finish.

By understanding the nuances of 16d nails—their sizing, types, and best applications—you can choose the right fastener for any project. Remember, selecting the right nail isn’t just about getting the job done; it’s about doing it right.

- How to Remove Water Stains from Fabric: A Complete Guide - April 26, 2025

- How to Get Motor Oil Out of Clothes: Proven Methods & Expert Tips - April 26, 2025

- How to Get Deodorant Out of Black Shirts: Easy Stain Removal Guide - April 26, 2025