This guide provides comprehensive information on the ampacity of 8 AWG wire, addressing critical factors like conductor material, insulation type, ambient temperature, and adherence to the National Electrical Code (NEC). Understanding these factors is crucial for safe and compliant electrical installations.

Decoding 8 AWG Ampacity

Ampacity, short for ampere capacity, defines the maximum current a conductor can safely carry without exceeding its temperature rating. For 8 AWG wire, this value isn’t fixed but depends on several interacting factors. Exceeding the ampacity can lead to overheating, insulation damage, and potentially fire hazards.

Factors Influencing 8 AWG Ampacity

Several key factors influence the ampacity of 8 AWG wire:

Conductor Material: Copper vs. Aluminum

The conductor material significantly impacts ampacity. Copper, with its superior conductivity, allows for higher current flow compared to aluminum. An 8 AWG copper wire will have a higher ampacity than an equivalent aluminum wire. This difference arises from aluminum’s higher resistivity, which leads to increased heat generation at the same current.

Temperature’s Impact

Ambient temperature and the wire’s insulation temperature rating are crucial. Higher temperatures reduce a wire’s current-carrying capacity. The NEC provides ampacity ratings for various temperature thresholds (e.g., 60°C, 75°C, 90°C). For instance, an 8 AWG copper conductor with 90°C-rated insulation has a higher ampacity than one with 60°C-rated insulation.

Insulation Type Considerations

The type of insulation surrounding the conductor influences its temperature rating. Common insulation types like THHN/THWN-2 have specific temperature ratings impacting the overall ampacity of the 8 AWG wire. Selecting the appropriate insulation type for the intended environment is, therefore, essential.

NEC Guidelines and the 80% Rule

The NEC provides essential safety guidelines for electrical installations, including ampacity ratings. Critically, the “80% rule” recommends limiting continuous loads (operating for three hours or more) to 80% of the wire’s rated ampacity. This safety margin mitigates risks associated with potential fluctuations and long-term operation. To determine the proper 8 gauge wire amp rating, consult the latest NEC edition.

Common Applications of 8 AWG Wire

8 AWG wire finds application in various residential and commercial settings, including:

- Feeding Subpanels: Distributing power from the main electrical panel to subpanels often necessitates 8 AWG wire, especially when the subpanel serves a substantial load.

- Powering Appliances: Heavy-duty appliances like electric ranges, ovens, clothes dryers, and welders often utilize 8 AWG wiring due to their high current draw. Knowing the 8 gauge wire amps is essential for selecting the correct overcurrent protection device.

- Other Applications: 8 AWG wire may also be used for heavy-duty lighting systems and other applications requiring higher current capacity.

Safety and Potential Hazards

Disregarding 8 AWG ampacity limits can lead to several hazards:

- Overheating: Excess current leads to excessive heat generation within the conductor, potentially damaging the insulation and the wire itself.

- Fire Hazard: Overheating creates a significant fire risk, especially if the insulation melts or flammable materials are nearby.

- Circuit Failure: Overloaded circuits can trip breakers or blow fuses, resulting in power outages and potential damage to connected equipment.

Always ensure compliance with NEC guidelines and consult a qualified electrician for any uncertainty regarding your wiring project.

Ampacity Charts and Examples

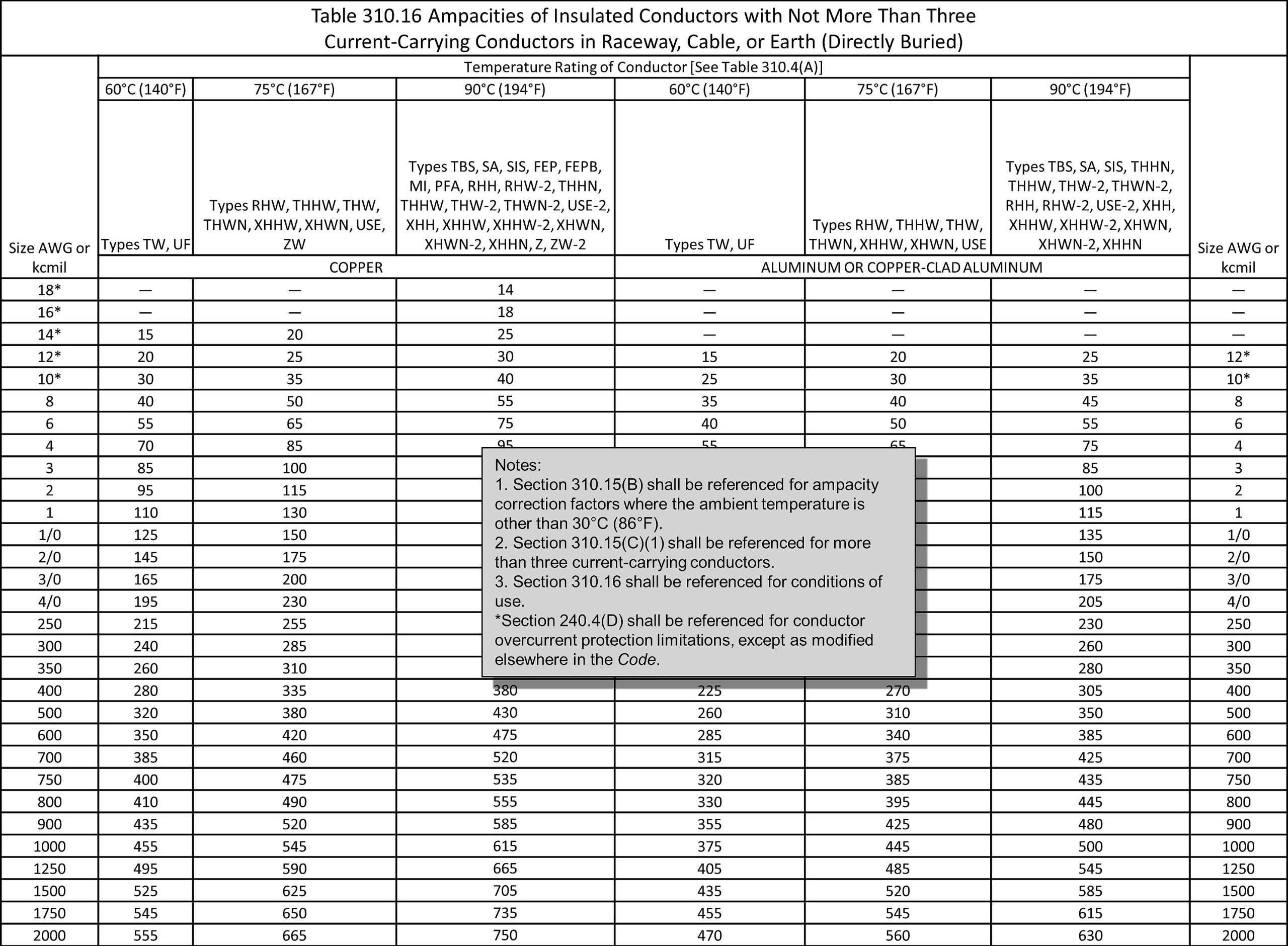

The NEC provides detailed ampacity tables that outline specific values for different wire sizes, materials, insulation types, and temperature ratings. Always refer to the latest NEC edition for accurate information. An example for 8 AWG copper wire with THHN/THWN-2 insulation is:

| Temperature Rating (°C) | Maximum Ampacity (Amps) | 80% Ampacity for Continuous Load (Amps) |

|---|---|---|

| 60 | 40 | 32 |

| 75 | 50 | 40 |

| 90 | 55 | 44 |

Advanced Considerations

Beyond the basics, other factors can influence ampacity:

Derating Factors

When multiple conductors are bundled together in a conduit, their ampacity is reduced due to restricted heat dissipation. The NEC provides derating factors to adjust for this effect, ensuring safe operation in bundled installations.

Altitude Effects

At higher altitudes, where air density is lower, the wire’s ability to dissipate heat decreases, potentially requiring further ampacity adjustments.

Voltage Drop Concerns

While not directly related to ampacity, voltage drop becomes significant with longer wire runs. Excessive voltage drop can lead to inefficient operation of electrical equipment. Proper wire sizing, including considering voltage drop, is crucial for optimal system performance.

Ongoing Research

Research into wire materials, insulation, and installation methods is ongoing. New developments may lead to updated ampacity ratings and safety guidelines. Staying informed about the latest NEC revisions and research findings is essential for ensuring safe and compliant electrical installations.

This guide provides a practical and comprehensive overview of 8 AWG ampacity. Always prioritize electrical safety and consult the NEC and qualified professionals for specific guidance on your wiring projects. Remember, respecting electricity’s power and following established safety protocols is paramount for safe and reliable electrical systems.

- Backsplash For Gray Cabinets: Choosing the Right Backsplash Style - December 13, 2025

- Gray And White Backsplash: Ideas For Timeless Style - December 12, 2025

- Gray Kitchen Backsplash Ideas: Find Your Perfect Gray Tile - December 11, 2025