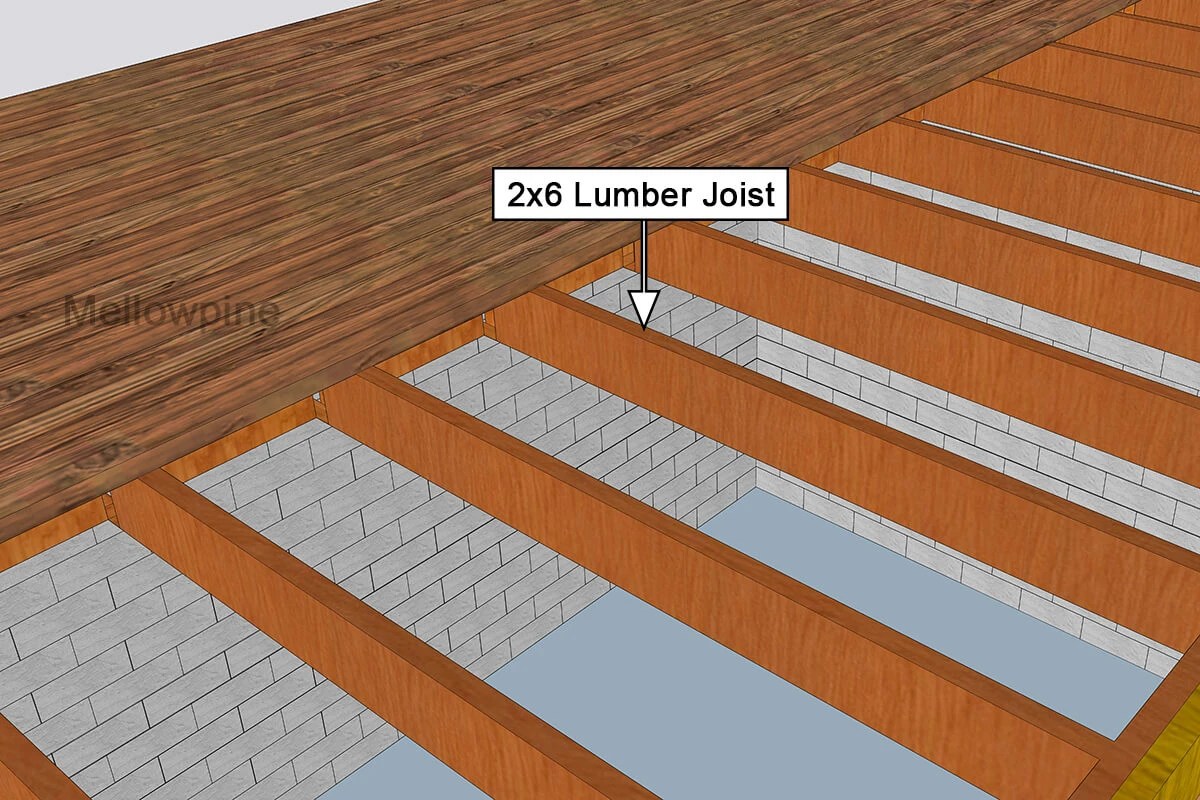

Unlock the potential of 2×6 lumber by understanding its structural capabilities. This comprehensive guide decodes 2×6 span charts, empowering you to design safe and code-compliant floors, roofs, and decks. From understanding load-bearing factors to navigating building codes, this resource equips you with the knowledge to build with confidence.

Decoding the 2×6 Span Chart

A 2×6 span chart is a critical tool in construction, providing the maximum horizontal distance a 2×6 lumber piece can safely span without structural failure. Think of it as a roadmap, guiding you towards safe and compliant building practices. This guide illuminates the intricacies of these charts, enabling you to make informed decisions for your projects.

Factors Influencing Span Limitations

Several interconnected factors influence a 2×6’s maximum allowable span. Understanding these variables is crucial for accurate span determination:

-

Wood Species: The inherent strength of wood varies significantly depending on the species. Southern Yellow Pine, known for its density and resilience, generally allows for longer spans than Spruce-Pine-Fir South (SPFs), which tends to be less dense. Douglas Fir-Larch and Hem-Fir each have their own strength profiles, affecting how they perform as structural members.

-

Grade: Lumber is graded based on its structural quality, with higher grades signifying fewer defects and greater strength. “Select Structural” and #1 grades typically permit longer spans than #2 or lower grades. The grade stamp on your lumber is a key indicator of its load-bearing capacity.

-

Load (Live & Dead): The total load a 2×6 must bear comprises the dead load (the weight of the structure itself) and the live load (the weight of occupants, furniture, snow, etc.). Heavier loads necessitate shorter spans or closer joist/rafter spacing.

-

Spacing: Decreasing the spacing between joists or rafters effectively increases their combined load-bearing capacity. For instance, 16-inch on-center spacing allows for a longer span than 24-inch spacing, as the load is distributed more effectively.

-

Application: The intended use of the 2×6 (floor joist, ceiling joist, rafter, decking) dictates different span limitations. Floor joists, for example, typically experience greater loads and thus have shorter allowable spans compared to ceiling joists. Decking, with its exposure to weather and potential for concentrated loads, presents unique span considerations.

-

Moisture Content: Treated lumber, often used for outdoor applications, may exhibit different strength properties compared to untreated lumber due to its higher moisture content. This can impact span calculations, especially for decking.

Navigating Span Tables and Calculators

Span Tables

Span tables offer a structured approach to determining allowable spans. They present data for various lumber sizes, species, grades, spacings, and load conditions. Referencing the correct table is crucial for accurately determining the maximum span for your specific project. Always ensure your chosen table aligns with the intended application (floor joist, rafter, etc.) and the applicable building codes. You can find these tables from reputable organizations such as the Southern Forest Products Association (SFPA), the American Wood Council (AWC), the Engineered Wood Association (APA), and various lumber manufacturers like Weyerhaeuser.

Span Calculator

For more complex scenarios or quick estimations, online span calculators can be invaluable. These tools allow you to input your project parameters (wood species, grade, load, spacing, application) and receive an instant span calculation. However, remember that calculator results should be verified against official span tables and building codes. Our website offers a free span calculator to assist you in your project planning.

Ensuring Code Compliance

Building codes, like the International Residential Code (IRC), are instrumental in ensuring structural safety. They define maximum allowable spans based on various factors and local conditions. Always consult the latest edition of the IRC and your local building codes, as they may have more stringent requirements based on regional factors like snow loads or seismic activity. Local codes supersede national guidelines, so compliance with both is essential.

Adhering to Safety Precautions

While span charts and calculators are powerful tools, they shouldn’t replace professional advice. For complex designs, unusually heavy loads, or 3 gang box installations that affect structural integrity, consulting with a structural engineer is paramount. They can provide tailored guidance, ensuring your project is structurally sound and compliant with all applicable building codes. Remember, a margin of safety is always prudent. Consider using a slightly shorter span than the maximum allowed to account for unforeseen circumstances or variations in lumber properties.

How Far Can a 2×6 Span?

The answer to “how far can a 2×6 span?” is nuanced, depending on the interplay of the factors discussed above. While under ideal conditions a 2×6 could potentially span up to 12 feet, 6 inches for floor joists, this is a theoretical maximum. Real-world scenarios often require shorter spans due to load variations, wood quality, and code requirements. Always consult span tables and your local building codes for definitive guidance.

Choosing the Right Lumber for a 10-Foot Span

Determining the appropriate lumber size for a 10-foot span isn’t simply a matter of choosing a 2x dimension. It requires careful consideration of load, wood species, grade, spacing, and building codes. While a 2×8 might be suitable in some cases, other situations may necessitate a 2×10 or even larger lumber to ensure structural integrity and safety. Span tables and professional consultation are invaluable in making this determination.

Are 2x6s Strong Enough for Floor Joists?

2x6s can be used for floor joists, provided they meet the requirements outlined in the span tables and building codes for your specific project. However, factors like load, spacing, and wood species play crucial roles. For longer spans or heavier loads, using 2x8s or 2x10s might be necessary to ensure adequate support and prevent excessive deflection or potential structural failure. Consulting with a structural engineer is highly recommended, especially when dealing with unusual designs or heavy load conditions.

Cost-Benefit Analysis and Environmental Considerations

Choosing the right lumber size involves balancing cost and structural requirements. While larger lumber dimensions offer greater strength and longer spans, they also come at a higher cost. Optimizing joist spacing can allow for using smaller lumber dimensions while maintaining structural integrity, potentially reducing material costs. Furthermore, considering the environmental impact of different wood species is becoming increasingly important. Sustainable forestry practices and the use of engineered lumber products can contribute to environmentally conscious building choices.

Future Trends in Building Materials

The construction industry constantly evolves, with ongoing research leading to new materials and techniques. Engineered lumber products, like cross-laminated timber (CLT) and laminated veneer lumber (LVL), are gaining popularity due to their strength, consistency, and sustainability. These materials may offer alternative solutions for longer spans, potentially impacting the future use of traditional lumber dimensions. Stay informed about these advancements to make informed decisions for your projects.

Conclusion

Mastering the complexities of 2×6 span charts empowers you to create structurally sound and code-compliant buildings. By understanding the factors affecting span, diligently consulting span tables and calculators, and adhering to safety precautions and building codes, you lay a solid foundation for your projects. Remember, accurate span calculations are paramount for ensuring safety and preventing costly structural issues down the line. When in doubt, consult a professional. The expertise of a structural engineer can provide invaluable peace of mind and contribute to a successful and enduring building project.

- Annapolis Mall Map & Directory: Find Stores, Restaurants & More - March 29, 2025

- Angel of Harmony Statue Vandalized at St. Louis Cathedral Basilica - March 29, 2025

- Amur River Maple ( Acer ginnala): A Comprehensive Guide (Including Invasiveness) - March 29, 2025