Discover the impressive current carrying capacity of 8 gauge wire amps and learn how to select the right gauge for your project’s electrical demands; while you’re at it, investigate the surprising strength and versatility of a 501 lally columns for your next construction project.

This guide provides comprehensive information on the ampacity of 8 gauge wire and safe usage practices. Understanding these principles is crucial for any electrical project, ensuring both functionality and safety.

Determining 8 Gauge Wire Ampacity

8 AWG wire ampacity isn’t a fixed number. It depends on several interacting factors, including the conductor material (copper or aluminum), insulation type (THHN, TW, etc.), and ambient temperature. Adhering to the National Electrical Code (NEC) is paramount for safety and code compliance.

Conductor Material: Copper vs. Aluminum

The conductor material significantly influences ampacity. Copper, with its superior conductivity, allows for higher current flow than aluminum. This means an 8 AWG copper wire generally handles a higher amperage than an equivalent aluminum wire. For instance, 8 AWG copper THHN/THWN-2 is rated for 55 amps at 90°C (per NEC), while 8 AWG aluminum is typically rated around 45 amps at the same temperature. Research suggests that the difference in conductivity stems from the atomic structure of each metal and how readily electrons can move within them.

Insulation Type: Temperature Ratings

Insulation acts as a protective barrier and also dictates the maximum temperature the wire can withstand. Different insulation types have different temperature ratings. For example, THHN/THWN-2 insulation, rated for 90°C, permits a higher ampacity than TW insulation, rated for 60°C. This is because higher temperature-rated insulation can safely tolerate higher operating temperatures, thus allowing the wire to carry more current.

Ambient Temperature: Derating Factors

The surrounding temperature, or ambient temperature, also impacts ampacity. Higher ambient temperatures reduce the wire’s ability to dissipate heat, effectively lowering its safe current-carrying capacity. The NEC provides derating factors to adjust ampacity based on ambient temperature. In hotter environments, you’ll likely need to derate the wire’s ampacity to maintain safety.

Installation Methods: Bundling and Conduit

The installation method further influences ampacity. Wires bundled together in a conduit or cable generate more heat than individually run wires. This heat buildup necessitates derating the ampacity of each wire within the bundle. Similarly, wires enclosed in conduit may experience higher temperatures than those in free air, potentially requiring further derating.

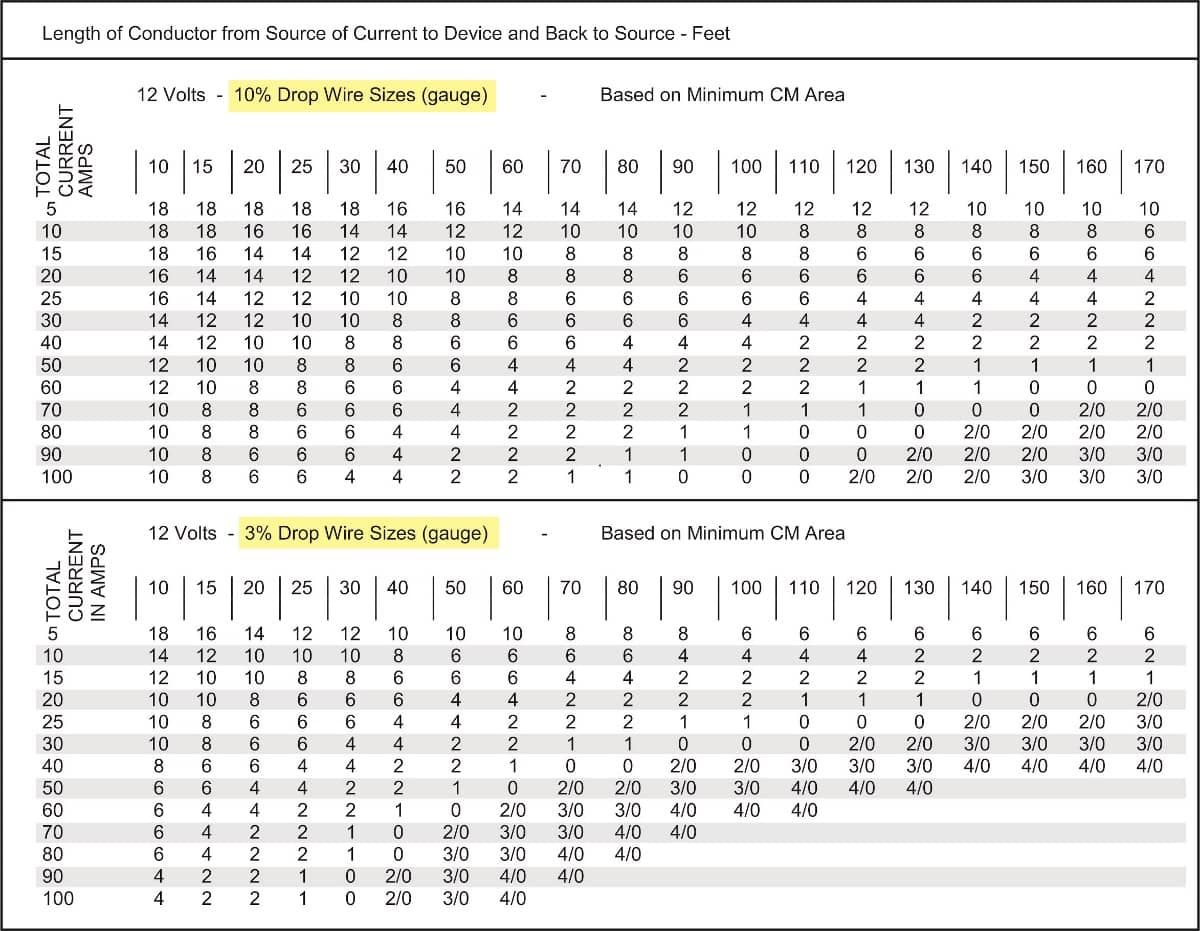

Wire Length: Voltage Drop Considerations

While not directly related to ampacity, wire length affects voltage drop. Longer wire runs result in greater voltage loss due to resistance. For extended circuits, a larger gauge wire (smaller AWG number) might be necessary to mitigate voltage drop and ensure adequate voltage reaches the destination. This is particularly important for maintaining the efficiency and proper operation of connected devices.

The National Electrical Code (NEC): Your Safety Guide

The NEC provides comprehensive ampacity tables, such as Table 310.16, which specify safe current limits based on conductor material, insulation type, temperature rating, and other installation factors. Consulting the NEC is not just good practice, but often a legal requirement for electrical installations. It is your authoritative guide for ensuring a safe and compliant electrical system.

Illustrative Ampacity Chart (Always Consult the NEC for Definitive Values)

| Wire Material | Insulation Type | Temperature (°C) | Approximate Ampacity (Amps) |

|---|---|---|---|

| Copper | THHN/THWN-2 | 90 | 55 |

| Copper | TW | 60 | 40 |

| Aluminum | THWN-2 | 90 | 45 |

Important: This chart provides approximate values for illustrative purposes. Always consult the latest edition of the NEC for definitive ampacity ratings and any required adjustments for your specific installation conditions.

Addressing Common Questions

This section tackles some frequently asked questions about 8 gauge wire and its ampacity in specific scenarios.

Can 8 Gauge Wire Handle 60 Amps?

In most practical applications, 8 gauge wire cannot safely handle a 60-amp load. While some specific 8 AWG copper wires might theoretically approach this capacity under ideal laboratory conditions, real-world installations require adherence to safety codes and derating factors, which generally limit 8 AWG to lower amperages. Using 8 gauge wire for a 60-amp circuit would violate the NEC and pose significant fire hazards due to overheating. For 60-amp circuits, 6 AWG copper wire or larger is typically required.

Can 8 Gauge Wire Handle 50 Amps?

Whether 8 gauge wire can handle 50 amps depends on the factors discussed earlier, primarily the conductor material (copper being better than aluminum) and the temperature rating of the insulation. Even if the wire’s listed ampacity is 50 amps or slightly higher, the 80% rule for continuous loads (those running for three hours or more) often requires derating. This means reducing the maximum current to 80% of the rated ampacity. Therefore, ensuring 8 gauge wire can safely carry 50 amps requires careful consideration of all influencing factors and adherence to the NEC. Consulting a qualified electrician is highly recommended for confirming suitability and ensuring a safe installation.

Safe Wiring Practices

- Select the Right Gauge: Always choose the appropriate wire gauge based on the electrical load, circuit length, and environmental conditions.

- Overcurrent Protection: Install properly sized circuit breakers or fuses to protect the circuit from overloads and prevent fire hazards.

- Proper Installation: Ensure proper wire installation, including secure connections and appropriate routing to maximize heat dissipation.

- Consult a Professional: For complex projects or when in doubt, consult a licensed electrician to ensure safety and code compliance.

Ongoing Research and Future Trends

Ongoing research constantly explores new materials and technologies to enhance wire performance and ampacity. Developments in insulation materials and conductor alloys may lead to higher ampacities in the future. Staying updated on these advancements is crucial for staying at the forefront of safe and efficient wiring practices.

This comprehensive guide aims to equip you with the knowledge to make informed decisions about using 8 gauge wire safely and effectively. Remember, prioritizing safety and adhering to the NEC are fundamental for any electrical project.

- How to Get Motor Oil Out of Clothes: Proven Methods & Step-by-Step Guide - April 25, 2025

- How to Get Mothball Smell Out of Clothes: A Complete Guide - April 25, 2025

- How to Get Highlighter Out of Clothes: Easy & Effective Stain Removal Guide - April 25, 2025