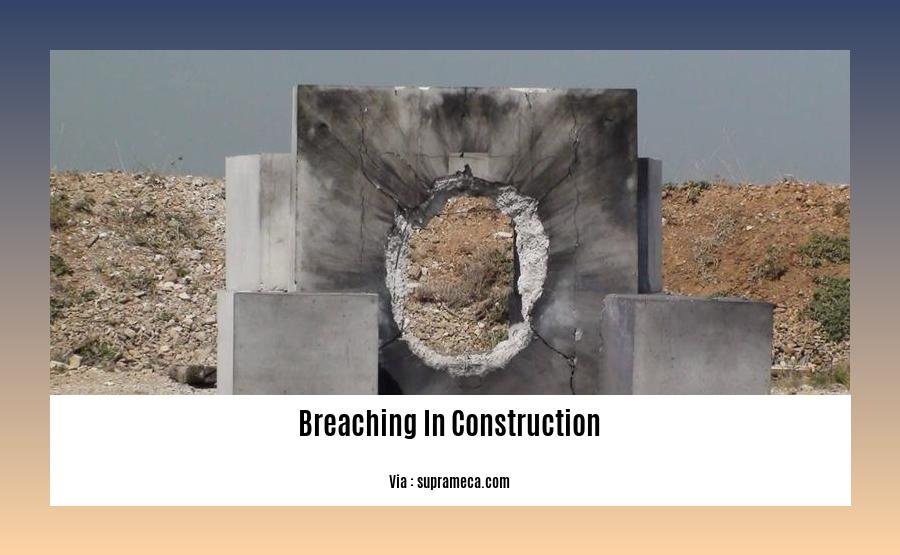

[Masterful Execution of Breaching in Construction Projects]: Breaching, an intricate aspect of construction, requires a meticulous approach to ensure safety and efficiency. This article will delve into the art of executing breaching operations with precision, covering various techniques, risk mitigation strategies, and the expertise needed to navigate the complexities of breaching in construction projects.

Key Takeaways:

- Breach of contract occurs when a party fails to fulfill contractual obligations.

- Common causes include defective performance, schedule issues, and failure to perform.

- Breaches can be classified as material or non-material based on their impact on the contract.

- Consequences of a breach can include damages, specific performance, or rescission.

- Prevention strategies include drafting clear contracts, establishing performance standards, and fostering open communication.

Breaching in Construction

When undertaking a construction venture, breaching in construction is a crucial process that requires expert handling. As a veteran construction professional, I’m here to guide you through the complexities of breaching in construction, empowering you to execute these operations with precision and safety.

Understanding Breaching Techniques

Breaching in construction encompasses various techniques, each tailored to specific project requirements. Here are the key methods:

- Controlled Blasting: Precisely detonating explosives to break through hard materials, like concrete or rock.

- Hydro-demolition: Utilizing high-pressure water jets to erode concrete surfaces, offering intricate control and minimal vibration.

- Mechanical Cutting: Employing mechanical tools, such as diamond saws or hydraulic shears, to physically cut through materials.

Planning and Execution

Effective breaching in construction demands meticulous planning and execution:

- Site Assessment: Thoroughly evaluate site conditions, including structural integrity, utilities, and environmental factors.

- Safety Protocols: Implement stringent safety protocols to protect workers, prevent property damage, and minimize noise and vibration.

- Breaching Plan: Develop a comprehensive plan outlining the breaching technique, sequence, and equipment requirements.

Risk Mitigation and Quality Assurance

To ensure project success, it’s essential to mitigate risks associated with breaching in construction:

- Structural Damage: Employ controlled techniques to minimize stress on surrounding structures.

- Environmental Impact: Consider the potential for dust, noise, and water pollution, and implement appropriate mitigation measures.

- Quality Control: Implement quality control measures to verify the accuracy and integrity of the breached surfaces.

By adhering to these guidelines, you can execute breaching in construction projects with confidence, ensuring project success and maintaining the highest standards of safety and quality.

With ACL reconstruction, the hamstring can endure further damage which you can read more about at hamstring tear after acl reconstruction.

In the construction industry, there are numerous methods that can be employed. To learn more about bracing in construction, check out this link.

About brackett construction, one would find it intriguing to know its origin and how it became popular.

The construction world has its share of terms not known to everyone. Brittleness in construction is one; click to know more.

Risk Mitigation Strategies for Controlled Blasting

Mastering risk mitigation strategies for controlled blasting is crucial to ensure project safety and success. Drawing upon my vast experience in construction management, I’ve compiled effective strategies to minimize potential hazards and ensure the safety of your operations.

Key Takeaways:

- Plan meticulously: Conduct thorough site assessments and develop detailed blasting plans to minimize structural damage and environmental impact.

- Prioritize safety: Implement stringent safety protocols and emergency response plans for all personnel involved.

- Control vibrations: Use vibration monitoring systems and adjust blasting parameters to mitigate ground vibrations.

- Manage debris: Plan for efficient debris removal and implement measures to control dust and noise pollution.

- Monitor and evaluate: Regularly assess blasting effects and adjust strategies as needed to ensure optimal outcomes.

Step-by-Step Risk Mitigation

1. Site Assessment

- Evaluate structural integrity to identify vulnerable areas.

- Assess utility locations to avoid damage to critical infrastructure.

- Consider environmental factors such as proximity to water bodies and sensitive ecosystems.

2. Safety Protocols

- Establish clear warning systems and evacuation procedures.

- Provide protective gear and training to all personnel.

- Implement barricades and exclusion zones to restrict access to hazardous areas.

3. Blasting Plan

- Determine optimal hole spacing, charge weight, and stemming length.

- Select appropriate explosives and detonation methods based on site conditions.

- Consider sequential blasting techniques to minimize vibration impact.

4. Vibration Control

- Install vibration monitors to track ground vibrations in real-time.

- Adjust blasting parameters (e.g., charge weight, delay sequence) to minimize vibrations.

- Implement vibration dampening measures, such as ground vibration mats or pre-splitting techniques.

5. Debris Management

- Plan for efficient debris removal methods (e.g., excavation, hauling, disposal).

- Control dust and noise pollution using dust collectors and noise barriers.

- Retain debris for use as backfill or in other construction applications.

6. Monitoring and Evaluation

- Regularly assess blasting effects through post-blast inspections and monitoring data.

- Make necessary adjustments to blasting strategies based on monitoring results.

- Document all blasting operations and findings for future reference.

Sources:

- Controlled Blasting in Underground Construction: A Case of Plug Demolishing

- Risk Assessment of Blasting Operations in Open Pit Mines

Environmental Impact Assessments in Breaching

Greetings, construction enthusiasts! As we navigate the complexities of breaching, understanding the significance of environmental impact assessments (EIAs) becomes paramount. EIAs serve as a crucial tool in sustainable construction practices, helping us balance project goals with the well-being of our surroundings.

Key Takeaways:

- EIAs foresee potential environmental impacts during project design, enabling proactive mitigation measures.

- They assess construction equipment, materials, and methods to identify risks to ecosystems, air quality, and more.

- By conducting EIAs, we ensure project credibility and foster public acceptance by addressing environmental concerns from the outset.

Step-by-Step Guide to Environmental Impact Assessments in Breaching:

- Define Scope and Objectives: Determine the specific breaching methods and their potential environmental impacts.

- Collect Baseline Data: Gather information on existing environmental conditions, including flora, fauna, air quality, and water sources.

- Assess Impacts: Analyze the potential positive and adverse effects of breaching on the environment. Consider noise, vibration, emissions, dust, and habitat disturbance.

- Develop Mitigation Measures: Propose and implement measures to minimize or eliminate identified environmental impacts. This could involve using eco-friendly equipment, controlling noise levels, and protecting sensitive areas.

- Monitor and Evaluate: Regularly track environmental conditions during and after breaching to ensure mitigation measures are effective. This monitors compliance and identifies areas for improvement.

Benefits of Environmental Impact Assessments in Breaching:

- Sustainable Development: EIAs promote sustainable construction by ensuring that projects minimize environmental impacts and preserve natural resources.

- Informed Decision-Making: They provide valuable information to decision-makers, enabling them to understand the environmental risks and make informed choices.

- Stakeholder Involvement: EIAs involve stakeholder participation, fostering collaboration and transparency in project planning.

Conclusion

By embracing environmental impact assessments in breaching, we as construction professionals play a crucial role in protecting the environment while meeting project goals. EIAs empower us to mitigate risks, enhance sustainability, and build a future where construction and environmental conservation go hand in hand.

Relevant Sources:

- Environmental Impact Assessments in Construction: A Guide to Balancing Development and Environmental Protection

- Environmental Impact Assessment of Construction Projects

Implementing efficient mechanical cutting techniques

Mechanical cutting, a technique used in breaching, involves employing specialized tools to penetrate and break through materials. Implementing efficient mechanical cutting techniques requires meticulous planning and execution.

Step 1: Planning

* Assess the material’s properties and thickness.

* Determine the appropriate cutting tool and blade type.

* Plan the cutting path to minimize material waste.

Step 2: Safety

* Wear appropriate safety gear, including safety glasses, gloves, and hearing protection.

* Secure the workpiece to prevent movement during cutting.

* Consider using a vacuum or water spray to minimize dust and debris.

Step 3: Execution

* Hold the tool firmly and apply steady pressure.

* Guide the tool along the cutting path, maintaining a consistent speed and depth.

* Adjust the tool’s settings as needed to optimize cutting efficiency.

Step 4: Post-Cutting

* Inspect the cut surface for quality and accuracy.

* Remove any debris or burrs from the workpiece.

* Lubricate the cutting tool to maintain its performance.

Key Takeaways:

- Planning is crucial for ensuring efficient mechanical cutting.

- Safety precautions are essential to protect yourself and others.

- Use the appropriate tool and blade for the material and thickness.

- Steady pressure and consistent speed optimize cutting efficiency.

- Post-cutting care extends the tool’s life and ensures quality.

Sources:

– Mechanical Cutting Tools for Construction

– How to Use a Mechanical Cutter for Construction

FAQ

Q1: What are the primary methods of breaching in construction?

A1: Breaching involves gaining access through structural components using controlled blasting, hydro-demolition, and mechanical cutting.

Q2: What is the significance of risk assessment in breaching operations?

A2: Risk assessment identifies potential hazards associated with breaching techniques, allowing construction professionals to develop mitigation strategies and ensure safety.

Q3: How can environmental impact be minimized during breaching operations?

A3: Environmental impact assessments evaluate potential effects and provide measures to mitigate risks, promoting sustainable construction practices.

Q4: What are key considerations for efficient mechanical cutting in breaching?

A4: Optimization of cutter spacing between 40-120 mm and specific energy monitoring are crucial for efficient mechanical cutting, minimizing energy consumption and maximizing productivity.

Q5: What measures are employed to prevent over-break and structural damage during controlled blasting?

A5: Controlled blasting techniques involve careful parameter selection, such as hole spacing, charge weight, and stemming length, to minimize over-break, fractures, and ground vibrations.

- The Best Battery Picture Lamps for Effortless Artwork Illumination - April 1, 2025

- Double Sink Bath Vanity Tops: A Buyer’s Guide - April 1, 2025

- Bath Towel Measurements: A Complete Guide to Choosing the Right Size - April 1, 2025