Unveiling the [- Leading Precast Construction Companies in India: Shaping the Future of Infrastructure -] presents a comprehensive overview of the precast construction sector in India. With the industry witnessing rapid advancements, this article highlights the key players driving innovation and shaping the future of infrastructural development in the country.

Key Takeaways:

- Leading precast construction companies in India include Precast Buildcon India Private Limited, Natraj Cement Prestressed Works, and Smart Built Prefab Private Limited.

- Precast concrete technology involves using prefabricated concrete elements for construction.

- Precast concrete products range from boundary walls and manholes to wind turbine towers and foundations.

- BASF Construction Chemicals Division offers precast admixtures, coatings, and repair products.

Precast Construction Companies in India

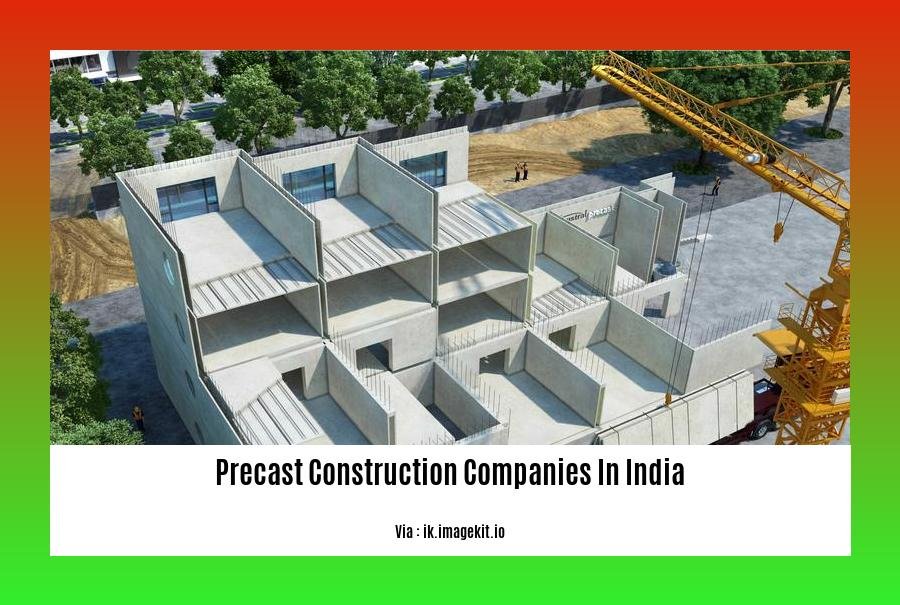

In India, the precast construction industry has experienced tremendous growth, transforming the infrastructure landscape. Numerous precast construction companies in India are leading this transformation, offering innovative solutions and redefining the construction process.

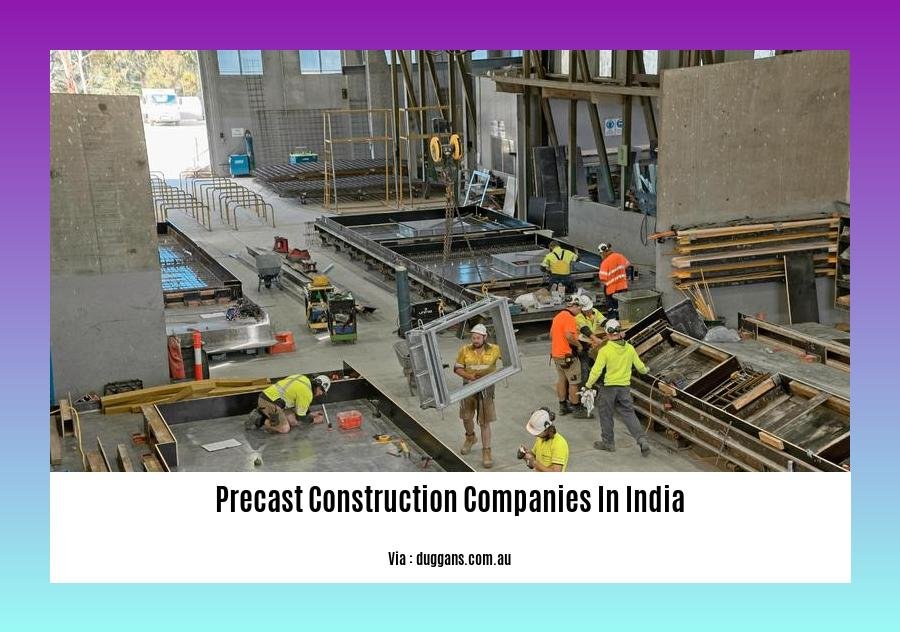

These companies specialize in precast concrete technology, where concrete elements are prefabricated in controlled factory environments and then assembled on-site. This approach offers several advantages, including:

- Faster construction time

- Enhanced quality control

- Reduced labor costs

- Improved safety

- Environmental sustainability

Prominent precast construction companies in India include:

| Company | Specialization |

|---|---|

| Precast Buildcon India Pvt Ltd | Boundary walls, manholes, pipes |

| Natraj Cement Prestressed Works | Wind turbine towers, bridges |

| Smart Built Prefab Pvt Ltd | Modular buildings, apartments |

| Suzlon Energy Limited | Wind turbine towers, foundations |

| Wind World India Limited | Wind turbine towers, substations |

| BASF Construction Chemicals Division | Precast admixtures, coatings, repair products |

These companies have played a vital role in India’s infrastructure development, contributing to iconic projects such as airports, stadiums, and bridges. Their commitment to quality and innovation has earned them a reputation for excellence in the industry.

power construction companies are changing the landscape of the industry. This is because of the increasing need for electricity and the growing demand for renewable energy sources. These companies are responsible for the construction of power plants, transmission lines, and distribution networks. They are also involved in the maintenance and repair of these facilities.

power line construction companies are at the forefront of this growth. They are responsible for the construction and maintenance of the power lines that transmit electricity from power plants to homes and businesses. These companies use specialized equipment and techniques to ensure that the power lines are safe and reliable.

precast building construction companies in india are using this technology to build a wide range of structures, including homes, offices, schools, and hospitals. Precast concrete is made by pouring concrete into molds and then curing it in a controlled environment. This process results in a strong and durable material that can be used to create a variety of shapes and sizes.

precast construction technology is also being used to build bridges, tunnels, and other infrastructure projects. Precast concrete is ideal for these applications because it is strong, durable, and can be installed quickly and efficiently.

precast house construction in bangalore is becoming increasingly popular. This is because precast concrete homes are durable, energy-efficient, and can be built quickly and easily.

Benefits of Precast Construction in India

Reduced Construction Costs

Precast technology reduces on-site construction time, materials, and labor, leading to significant cost savings.

Increased Efficiency

Precast elements are manufactured off-site in controlled environments, allowing for faster and more efficient installation.

Enhanced Quality

Factory-controlled production ensures consistent quality standards, minimizing errors and improving durability.

Improved Safety

Precast construction reduces the need for heavy equipment and minimizes on-site risks, promoting a safer work environment.

Reduced Waste and Pollution

Precast manufacturing utilizes precise measurements and controlled materials, decreasing waste generation and reducing environmental impact.

Key Takeaways:

- Precast construction offers cost-saving benefits due to reduced materials, labor, and on-site construction time.

- Enhanced efficiency is achieved through off-site production and faster installation.

- Improved quality is ensured by controlled factory environments and consistent standards.

- Safety is increased by minimizing on-site risks and reducing the need for heavy equipment.

- Waste and pollution are reduced through precision manufacturing and controlled materials.

Sources:

Precast Concrete Construction: Pros and Cons in Construction Practice

Benefits and Challenges of Precast Construction in India – A Review

Market Trends and Future Prospects

In the rapidly evolving Indian construction landscape, precast construction technology is poised for exponential growth. The industry is projected to reach a monumental USD 1.4 trillion by 2025. Driving this surge is the exponential growth of urban populations; by 2025, 68 cities in India will boast populations exceeding 1 million.

With the country’s burgeoning infrastructure needs, precast construction offers a potent solution. Its efficiency, quality, and sustainability make it an ideal choice for modern builders. Leading precast construction companies in India are embracing innovation, leveraging cutting-edge technologies to push the boundaries of this transformative technology.

These companies are actively involved in iconic projects, shaping the skyline of India’s urban centers. Precast construction has proven its mettle in diverse applications, from residential and commercial buildings to sprawling infrastructure projects. The future prospects for precast construction in India are indeed radiant.

Key Takeaways:

- India’s construction industry is projected to reach USD 1.4 trillion by 2025.

- The India Prefabricated Buildings Market is expected to grow at a CAGR of over 13% during 2024-2029.

- Precast construction offers advantages such as faster construction time, enhanced quality control, and reduced labor costs.

Sources:

- Mordor Intelligence: India Prefabricated Buildings Market

- TechSci Research: India Prefabricated Buildings Market

Case Studies of Successful Precast Projects in India

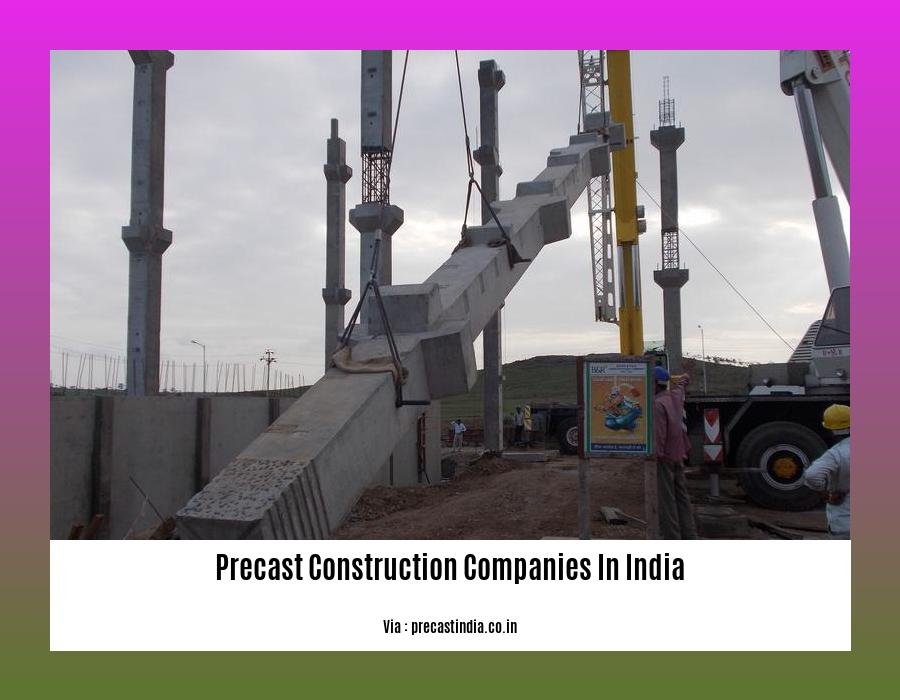

As demand for fast-track and cost-effective construction methods soars, precast technology has emerged as a revolutionary solution in India’s infrastructure landscape. By casting concrete components off-site in controlled environments, this technique offers significant advantages, including reduced construction time, enhanced quality control, and improved cost-effectiveness.

Key Takeaways:

- Precast technology has revolutionized India’s infrastructure landscape, enabling the construction of high-rise buildings, bridges, and other structures.

- Successful case studies demonstrate the benefits of precast concrete technology in terms of speed, cost, and quality.

- India’s precast industry is poised for continued growth as the demand for sustainable and efficient construction methods increases.

Successful Precast Projects in India

Numerous precast projects in India have showcased the versatility and efficiency of this technology. For instance, the construction of the Bandra-Worli Sea Link, a 5.6 km long cable-stayed bridge in Mumbai, utilized precast segments to expedite the project. The precast elements were cast in a dedicated fabrication yard and transported to the construction site, significantly reducing construction time compared to traditional methods.

Another notable project is the Jaipur Metro Rail Project. Precast technology was employed for the construction of elevated stations, pillars, and viaduct girders. The use of precast components ensured high-quality construction, reduced labor costs, and minimized disruption to the city’s traffic flow.

Benefits and Challenges of Precast Technology

- Benefits:

- Reduced construction time

- Improved quality control

- Reduced labor costs

- Improved safety

-

Reduced environmental impact

-

Challenges:

- Lack of standardized codes and regulations

- Limited availability of skilled labor

- High upfront investment

Despite these challenges, the Indian government is actively promoting the adoption of precast technology through incentives and initiatives. With its numerous benefits and the government’s support, precast construction is poised to play a significant role in shaping the future of infrastructure in India.

Citations:

Implementation of Precast Technology in India

Benefits and Challenges of Precast Construction in India – A Review

FAQ

Q1: What is precast technology and how is it used in India?

A1: Precast concrete technology involves constructing building elements off-site in a controlled environment. In India, it is used to speed up construction, improve quality control, reduce costs, and minimize environmental impact.

Q2: Name some leading precast construction companies in India.

A2: Some of the leading precast construction companies in India include Precast Buildcon India Private Limited, Natraj Cement Prestressed Works, Smart Built Prefab Private Limited, Suzlon Energy Limited, and Wind World India Limited.

Q3: What are the advantages of using precast technology in India?

A3: Precast technology offers several advantages in India, including reduced construction time, improved quality control, increased cost-effectiveness, and reduced environmental impact.

Q4: What are the challenges faced by the precast construction industry in India?

A4: The precast construction industry in India faces challenges such as a lack of standardization, certification, and testing facilities, contractual issues, and non-availability of specialized tools and equipment.

Q5: How is the future of precast construction in India?

A5: The future of precast construction in India is promising, driven by the growing demand for fast-track and cost-effective construction and the increasing popularity of precast technology in the construction of high-rise buildings.

- How to Get Rid of Ants in the Washroom: A Complete Guide - March 31, 2025

- How Much Does Ant Extermination Cost? (2024 Guide & DIY Options) - March 31, 2025

- Best Ant Bait for Carpenter Ants: A Complete Guide - March 31, 2025