Dive into the world of precast construction technology with our comprehensive guide [- Precast Construction Technology: A Comprehensive Guide to Design, Production, and Implementation]. This definitive resource will take you through every aspect of precast concrete components, empowering you with the knowledge to optimize project timelines, reduce costs, and achieve superior structural integrity.

Key Takeaways:

- Precast construction involves manufacturing concrete elements in a controlled environment, which are then transported and assembled at the construction site.

- It offers advantages such as faster construction times and cost-effectiveness due to efficient production processes.

- Types of precast elements include reinforced and prestressed concrete components.

- Precast construction requires significant initial investment and may have limited flexibility due to transportation constraints.

Precast Construction Technology

Precast Construction Technology: a transformative approach to modern construction, offers numerous advantages and unique applications. Here’s a comprehensive guide to design, production, and implementation:

Benefits of Precast Technology

- Accelerated Construction: Precast elements are manufactured off-site, enabling faster assembly on-site, reducing construction timelines significantly.

- Cost Savings: Efficient production processes and reduced labor costs make precast construction a cost-effective option.

- Enhanced Durability: Precast elements are manufactured under controlled conditions, ensuring quality and durability, leading to longer-lasting structures.

- Design Flexibility: Precast construction allows for diverse architectural designs and complex structural elements, offering design freedom.

Types of Precast Elements

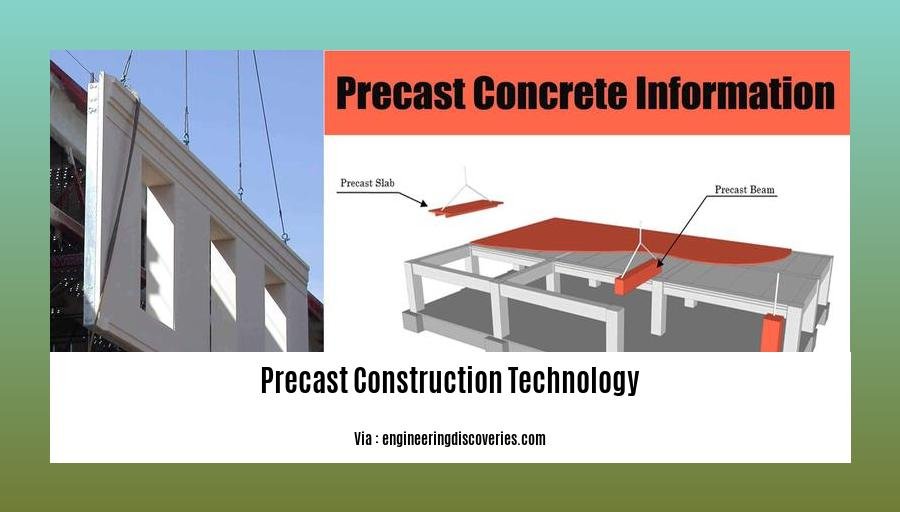

- Precast Reinforced Concrete Elements: Concrete components reinforced with steel bars for strength and durability.

- Precast Prestressed Concrete Elements: Concrete components reinforced with high-tensile steel cables or tendons to enhance load-bearing capacity and reduce cracking.

Design Considerations

- Structural Analysis: Engineers carefully analyze structural loads and forces to determine the optimal design of precast elements.

- Connection Design: Joints between precast elements require careful design to ensure load transfer and structural integrity.

- Quality Control: Strict quality control measures are essential throughout production to ensure the durability and performance of precast elements.

Production Process

- Formwork Preparation: Molds and forms are carefully prepared to ensure precise dimensions and surface finishes.

- Concrete Placement: High-quality concrete is poured into the molds and compacted to remove air voids.

- Curing: Precast elements are cured under controlled conditions to develop strength and durability.

Implementation

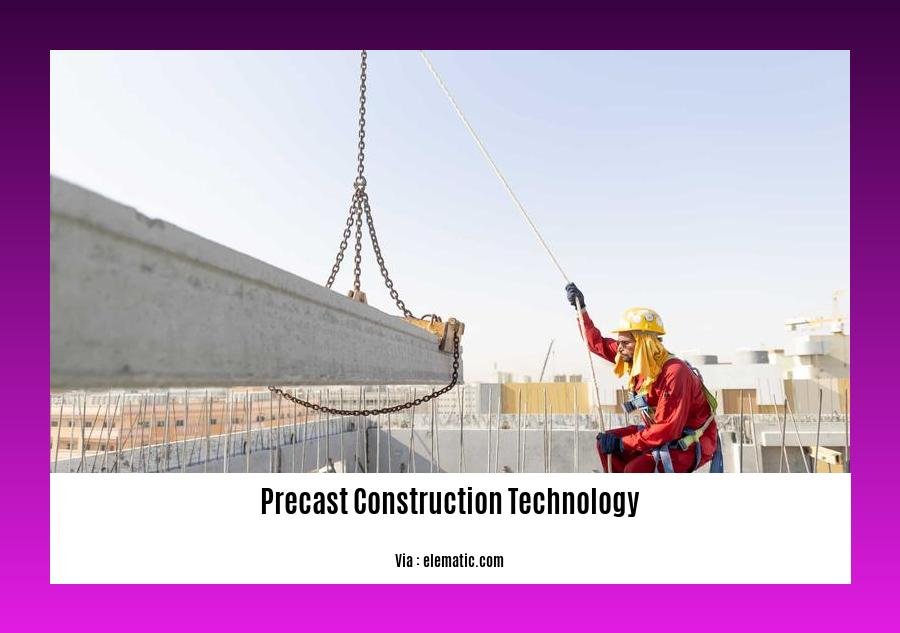

- Transportation: Precast elements are transported to the construction site using specialized equipment.

- Assembly: Elements are assembled on-site using cranes and other equipment, ensuring proper alignment and connections.

- Erection: The completed structure is erected, and final connections are made to ensure stability.

Applications

Precast construction technology finds applications in various construction sectors, including:

- Residential Buildings: Apartments, townhouses, and single-family homes.

- Commercial Buildings: Offices, shopping centers, and warehouses.

- Industrial Buildings: Factories, warehouses, and power plants.

- Infrastructure Projects: Bridges, tunnels, and retaining walls.

Conclusion

Precast construction technology offers numerous advantages, including accelerated construction, cost savings, and enhanced durability. Understanding the design, production, and implementation processes is crucial for successful precast projects. By adopting precast construction methods, architects, engineers, and contractors can create innovative and sustainable structures that meet the demands of modern construction.

Discover the leading power construction companies that can handle your project’s unique requirements with precision and expertise.

Find the most reputable power line construction companies known for their innovative solutions and commitment to safety.

Explore the top-rated precast building construction companies in India that specialize in delivering durable and cost-effective structures.

Connect with the best precast construction companies in India to transform your building dreams into a reality.

Unlock the potential of precast house construction in Bangalore with companies that offer cutting-edge techniques and exceptional craftsmanship.

Design and Engineering Considerations

Design Considerations

- Structural Analysis: Examine precast structures holistically, ensuring joints can withstand anticipated loads.

- Joint Design: Design joints to transmit loads and restrict movement for stability.

- Durability: Protect precast components from wear and tear during handling, storage, and transport.

- Transportation Coordination: Plan transportation routes and timing to optimize delivery and minimize delays.

- Construction Sequencing: Establish a meticulous installation sequence to minimize disruptions and streamline assembly.

Engineering Considerations

- Material Properties: Understand the properties of concrete and steel used in precast elements to optimize their performance.

- Load Analysis: Calculate and distribute loads effectively across precast components to ensure structural integrity.

- Connection Design: Engineer connections between precast elements to transfer forces and resist movement.

- Quality Control: Implement rigorous quality control measures throughout the design and production process to ensure precast elements meet specifications.

- Testing and Validation: Conduct thorough testing and validation procedures to verify the performance and safety of precast structures.

Key Takeaways:

- Structural analysis is crucial for ensuring the stability of precast structures.

- Joint design plays a key role in transferring loads and maintaining stability.

- Durability considerations protect precast components throughout their lifecycle.

- Transportation coordination optimizes delivery and minimizes delays.

- Construction sequencing ensures efficient and seamless assembly.

Relevant URL Sources:

- Design Considerations for Precast Structure

- Advances in Structural Engineering: A Review on Precast Structural Connections

Production and Implementation Strategies in Precast Construction

Embracing precast construction technology revolutionizes the construction industry, offering significant advantages in efficiency and productivity.

Key to successful precast projects is optimizing Production and Implementation Strategies, focusing on:

1. Automation in Precast Production

Leverage automation to enhance efficiency and sustainability throughout the production process, including formwork preparation, concrete placement, and curing. Automated systems improve accuracy, reduce labor costs, and minimize production time.

2. Lean Manufacturing Techniques

Implement lean manufacturing principles to streamline production, reduce waste, and improve overall quality. This involves optimizing material flow, minimizing lead times, and eliminating non-value-added activities.

3. Off-Site Precast Production

Shifting production off-site to specialized facilities allows for controlled environments, increased quality, and reduced construction time. Off-site prefabrication enables assembly-line efficiency and minimizes adverse weather impact.

4. Transportation and Logistics

Plan strategically for efficient transportation and logistics, minimizing storage and waiting time. Optimize routes, coordinate schedules, and utilize specialized equipment for safe and timely delivery.

5. Assembly and Erection

Plan and coordinate the assembly and erection of precast components meticulously, ensuring accurate alignment and secure connections. Sequence installation to minimize disruption and ensure rapid progress. Utilize advanced techniques like BIM (Building Information Modeling) for precise coordination and clash detection.

Key Takeaways:

- Production Automation: Enhances efficiency, reducing costs and improving quality.

- Lean Manufacturing: Streamlines production, minimizes waste, and speeds up project delivery.

- Off-Site Production: Provides a controlled environment for optimal precast component fabrication.

- Strategic Transportation: Minimizes delays and ensures timely delivery.

- Efficient Assembly: Enables rapid and precise installation of precast components.

Relevant URL Sources:

-

Modularisation Strategies for Individualised Precast Concrete Structures

-

Productivity Improvement in Precast Construction

Applications in Modern Construction

Modern construction methods, including precast concrete construction, have gained prominence in recent years. Precast concrete components offer speed, durability, and versatility in various construction applications.

Types of Applications:

- Residential buildings: Precast panels and slabs accelerate construction timelines and provide design flexibility for apartments, condos, and single-family homes.

- Commercial buildings: Precast elements are ideal for erecting high-rise structures, office towers, and shopping malls, ensuring fast assembly and minimizing disruption.

- Infrastructure projects: Precast girders, beams, and columns are commonly used in bridges, parking structures, and highway projects, enhancing project efficiency and safety.

Key Takeaways:

- Precast concrete enables accelerated construction timelines.

- It enhances durability and reduces construction waste.

- Precast technology offers versatility and adaptability in design.

- It is widely applied in residential, commercial, and infrastructure projects.

Citation:

- The Constructor: Modern Construction Methods – Details and Applications

- ScienceDirect: A Review of Emerging Trends & Advances in Construction Technology and Management

FAQ

Q1: What sets precast construction apart from conventional methods?

A1: Precast technology involves manufacturing components offsite, allowing for faster construction times and reduced labor costs.

Q2: Can you explain the types of precast elements used in construction?

A2: There are two primary types: reinforced concrete elements reinforced with steel bars and prestressed concrete elements reinforced with high-tensile steel for increased strength and reduced cracking.

Q3: What are the key benefits of using precast technology?

A3: Benefits include accelerated construction timelines, cost-saving production processes, and enhanced structural integrity compared to traditional methods.

Q4: Are there any potential drawbacks to precast construction?

A4: While precast construction requires a significant initial investment in manufacturing, it can have limitations in location flexibility due to the transportation of precast elements to the site.

Q5: What is the significance of joint design in precast structures?

A5: Joint design is critical for load transfer and movement restraint, ensuring the stability and durability of precast structures.

- Kitchen tiling wall: Elevate your kitchen with stylish wall tiles - December 16, 2025

- Gray Kitchen Backsplash Tile: Ideas for a Stylish Upgrade - December 14, 2025

- Backsplash For Gray Cabinets: Choosing the Right Backsplash Style - December 13, 2025