Embark on a journey into [- The Importance of Quality in Building Construction: A Guide for Ensuring Excellence]. In this comprehensive guide, we delve into the critical role of quality in construction, exploring the intricacies of quality assurance and project management. From understanding industry standards to implementing robust quality control processes, this guide serves as an invaluable resource for professionals seeking to deliver exceptional construction projects.

Key Takeaways:

- Construction quality ensures projects meet guidelines set in the scope of work.

- Quality assurance defines quality expectations, while quality control outlines the plan to achieve them.

- Procurement methods, construction methods, materials, design, and climate influence construction quality.

- To improve quality, implement a work list, establish workflows, conduct risk assessments, and standardize processes.

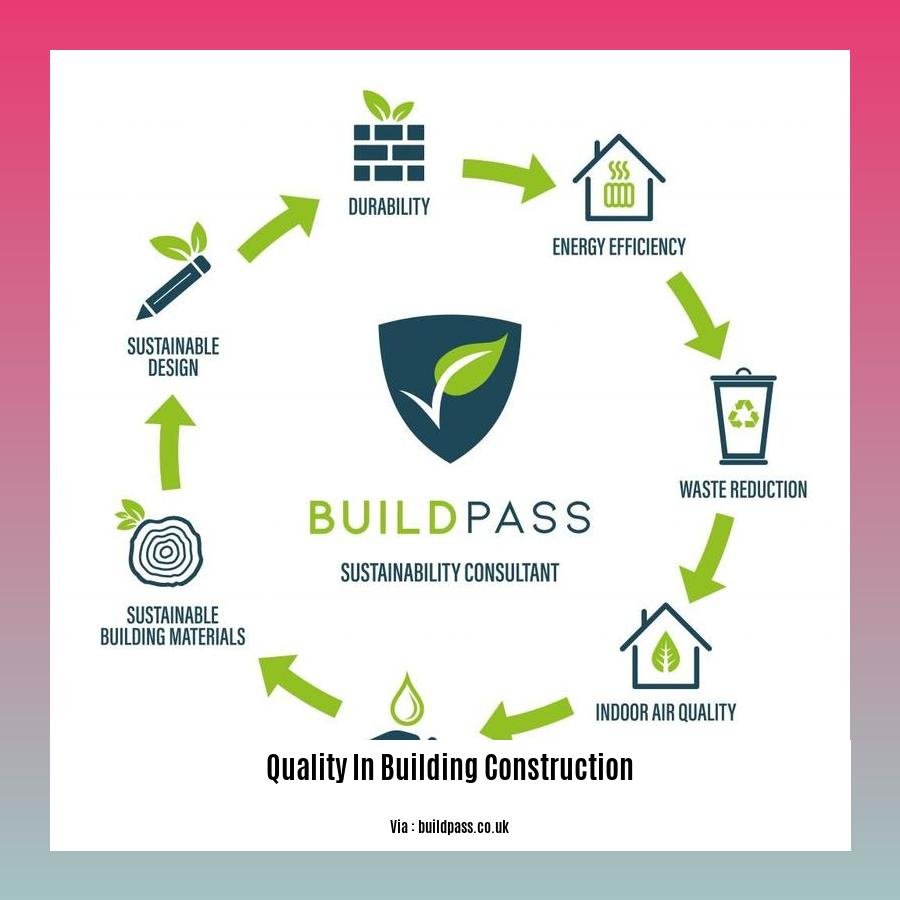

Quality in Building Construction

Producing a building that satisfies the established standards and matches its intended use is the essence of quality in building construction. It involves more than just using premium materials; it’s about employing expert knowledge and processes to ensure a structurally sound, durable, and safe structure.

Why Quality Matters

High-quality construction not only enhances the building’s aesthetic appeal but also guarantees:

- Structural Integrity: Withstanding external forces and ensuring a safe environment.

- Durability: Resisting deterioration and maintaining the building’s functionality over time.

- Occupant Safety: Creating a healthy and secure space free from potential hazards.

- Code Compliance: Adhering to legal requirements and industry standards.

- Value for Investment: Ensuring a building that retains its value and provides a positive return on investment.

Elements of Quality Construction

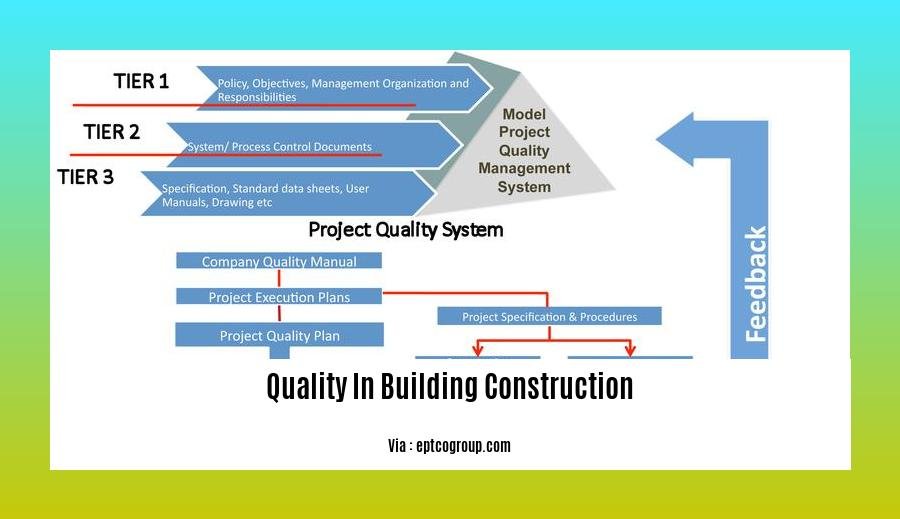

Two key elements ensure quality in building construction:

1. Quality Assurance (QA)

Defines the standards, processes, and communication channels necessary to achieve the desired quality.

2. Quality Control (QC)

Monitors and evaluates construction activities to ensure compliance with QA requirements.

Factors Influencing Quality

Several factors influence quality in building construction:

- Design: Clear and accurate blueprints minimize errors.

- Materials: Using high-quality materials ensures durability and performance.

- Procurement Methods: Collaboration with reputable suppliers guarantees material availability and quality.

- Construction Methods: Skillful and experienced contractors ensure proper execution.

- Inspection and Testing: Regular inspections and testing identify and address potential issues.

- Communication: Effective communication among stakeholders ensures alignment and avoids misunderstandings.

Steps to Ensure Quality

- Establish Clear Specifications: Outline detailed quality requirements, including materials, workmanship, and inspections.

- Implement Quality Control Plan: Develop and follow a plan that outlines QC procedures and responsibilities.

- Regular Inspections: Conduct regular inspections at key stages to identify and correct any deviations from specifications.

- Test and Verify: Perform tests and verifications to confirm compliance with standards and requirements.

- Continuous Improvement: Seek feedback, identify areas for improvement, and implement corrective actions to enhance quality in building construction practices.

- Find out more about our guidelines for QA and QC in Construction to get the right team for your project.

- Find out more about the importance of QA and QC in construction so your construction project becomes a success.

- Learn more about the necessary qualifications for construction to equip yourself with for an impactful construction career.

- Discover a comprehensive guide for implementing Quality Management in Construction Projects to ensure the efficiency of your project.

- Build a strong foundation for your construction company with our specialized Quality Management System that guarantees top-notch quality in every aspect of your operations.

Implementing a Quality Assurance Program

In the realm of construction, quality isn’t just an abstract concept; it’s the cornerstone of safety, durability, and occupant well-being. As builders, we have a responsibility to ensure that every project we undertake meets the highest standards of excellence. And that’s where a robust Quality Assurance (QA) program comes into play.

QA is like the blueprint for excellence. It sets the expectations, defines the processes, and provides a roadmap for achieving consistent, high-quality outcomes. By implementing a QA program, we can proactively identify and mitigate potential issues, ensuring that our projects are not only aesthetically pleasing but also structurally sound.

Key Takeaways:

- A QA program provides a framework for achieving and maintaining quality throughout the construction process.

- It involves setting clear quality standards, establishing inspection protocols, and conducting regular testing.

- A well-defined QA program reduces the risk of costly rework, enhances project efficiency, and improves customer satisfaction.

Steps to Implementing a QA Program:

- Define Quality Standards: Establish clear and measurable criteria for materials, workmanship, and overall project outcomes.

- Establish Inspection Protocols: Determine the frequency and methodology for inspections and testing based on project complexity and industry best practices.

- Conduct Regular Inspections: Implement a rigorous inspection schedule to monitor progress, identify deviations from standards, and address issues promptly.

- Document and Track Findings: Maintain detailed inspection reports and track the resolution of any identified deficiencies.

- Foster a Culture of Quality: Engage the entire project team in the pursuit of quality by promoting awareness, training, and continuous improvement.

By embracing a QA program and adhering to its principles, we can transform our construction sites into hubs of excellence, where safety, durability, and aesthetic appeal are not just goals but a reality.

Sources:

- Construct Quality Control: A Guide to Implement Process

- Quality Assurance manual for construction

Conducting Inspections and Testing

Conducting inspections and testing is crucial for ensuring the quality of building construction projects. These processes identify potential risks and ensure that construction elements meet specifications.

Types of Inspections and Tests

- Visual Inspections: Examining construction elements for visible defects or deviations from the plan.

- Structural Inspections: Assessing the integrity of load-bearing elements like beams, columns, and foundations.

- Mechanical Inspections: Evaluating the functioning of equipment and systems like HVAC, electrical, and plumbing.

- Material Testing: Conducting tests on materials like concrete, steel, and wood to ensure they meet quality standards.

Benefits of Inspections and Tests

- Early Detection of Defects: Regular inspections allow for early detection of potential problems, preventing costly repairs down the road.

- Compliance with Codes: Testing confirms whether construction elements meet specified codes and standards.

- Improved Safety: Inspections ensure that structural elements are sound, reducing the risk of accidents.

- Enhanced Quality: By verifying materials and workmanship, inspections improve the overall quality of the construction project.

Key Takeaways:

- Inspections and tests are vital for identifying and mitigating potential risks in building construction.

- Visual inspections identify visible defects, while structural and mechanical inspections assess the integrity of load-bearing elements and systems.

- Material testing ensures that materials meet quality standards.

- Benefits include early detection of defects, compliance with codes, improved safety, and enhanced quality.

Relevant URL Sources:

- The Importance of Construction Inspections and Testing

- Inspection and Testing in Construction Projects

Continuous Monitoring and Improvement

In the realm of building construction, continuous monitoring and improvement play a pivotal role in ensuring quality throughout the project lifecycle. This iterative process involves regular inspections, evaluations, and feedback loops to identify potential risks, address deviations, and enhance the overall quality of the structure.

Key Takeaways:

- Continuous monitoring allows for timely detection and mitigation of quality issues.

- Regular evaluation of quality metrics provides valuable insights for process optimization.

- Feedback from inspections and tests drives continuous improvement, fostering a culture of quality excellence.

- Continuous Monitoring and Improvement – A Proactive Approach

- Benefits of Continuous Monitoring and Improvement

- Quality Control in the Realm of Civil Engineering

- Construction Management: Enhancing Quality Control]

FAQ

Q1: How does quality control contribute to the overall success of a building construction project?

Q2: What are the key aspects of quality assurance in building construction?

Q3: How can construction professionals improve quality management processes on site?

Q4: What are the common challenges faced in maintaining quality standards in building construction?

Q5: How can the use of technology enhance quality control practices in building construction?

- The Best Battery Picture Lamps for Effortless Artwork Illumination - April 1, 2025

- Double Sink Bath Vanity Tops: A Buyer’s Guide - April 1, 2025

- Bath Towel Measurements: A Complete Guide to Choosing the Right Size - April 1, 2025