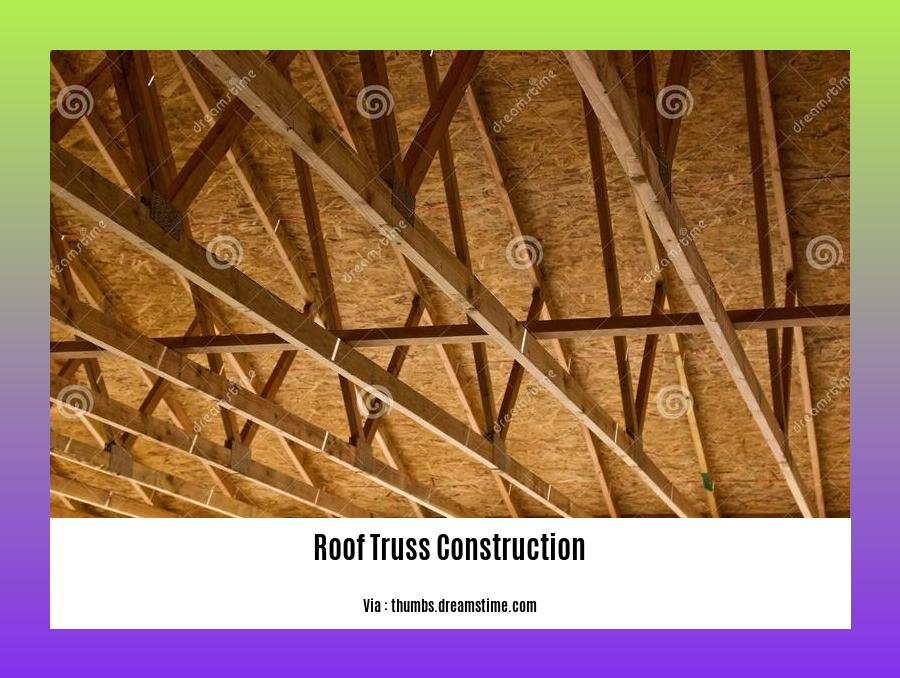

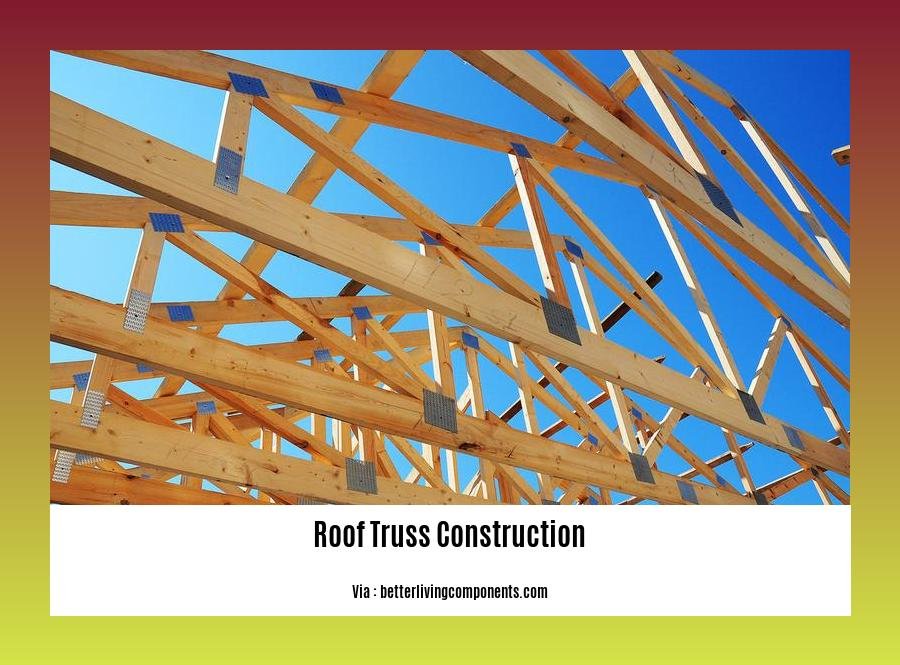

[- Innovative Solutions in Roof Truss Construction]: As the construction industry continues to evolve, the demand for innovative and efficient solutions in roof truss construction has become increasingly evident. This article explores the latest advancements and emerging techniques that are transforming the design and construction of roof truss systems.

Key Takeaways:

- Roof trusses are composed of two rafters that support the roof’s structure.

- They distribute loads to the walls efficiently.

- Various types of roof trusses exist, such as wood, flat, and scissors.

- Professional design tools can assist in creating a truss layout.

- Considerations for truss selection include weight, support, and aesthetics.

Effective Roof Truss Construction Solutions

There’s no denying their prominence in modern architecture, roof trusses gracefully support roofs across homes, commercial buildings, and industrial facilities. Their structural integrity and aesthetic appeal demand expertise and precision, which is where we step in.

To ensure a flawless roof truss construction project, meticulously consider these key factors:

-

Load Distribution: Trusses effectively transfer loads from the roof to the supporting walls, maintaining structural stability.

-

Material Selection: Choose materials wisely, considering strength, durability, and the project’s specific requirements.

-

Design Precision: Expert design is crucial. Each truss must be meticulously engineered to withstand the anticipated loads and environmental conditions.

-

Installation Expertise: Skilled installation is paramount, ensuring proper alignment and secure connections.

Remember, selecting the right truss type is essential. Each type serves a specific purpose:

-

Wood Trusses: Common and versatile, offering a wide range of shapes and sizes.

-

Flat Trusses: Ideal for flat roofs, providing support and drainage.

-

King Post Trusses: Used in steep-pitched roofs, transferring loads to a central vertical post.

-

Queen Post Trusses: Similar to king post trusses, but with two vertical posts.

-

Fink Trusses: Suitable for larger spans, featuring multiple triangular sections.

-

Attic Trusses: Create an attic space while supporting the roof.

-

Scissor Trusses: Ideal for vaulted ceilings, providing both structural support and aesthetic appeal.

Have you ever wondered what kind of equipment was used to build the roads we drive on? Check out our road construction equipment list and learn about the different types of machinery used in road construction! Learn all about the different materials used in road construction with our road construction materials guide. It covers everything from asphalt to concrete to gravel. If you’re looking for a reliable road construction service, look no further! Our road construction service can handle any job, big or small. We’re experts in all aspects of road construction, from planning and design to paving and maintenance. Need to know about roof construction? we have a step-by-step guide on roof construction process for you. Our guide covers everything from framing to roofing to finishing. And if you’re interested in learning more about roof valley construction details, we have a comprehensive guide that covers everything you need to know. We also have a guide on roof valley gutter construction details that covers everything you need to know about constructing a roof valley gutter.

Fabrication Techniques and Best Practices for Roof Trusses

Key Points:

- Employ computer-aided saws for precise angle and length cutting.

- Assemble trusses in climate-controlled environments for accuracy.

- Implement rigorous quality control measures throughout fabrication.

Fabrication Techniques:

Computer-Aided Cutting:

– Ensures precision and consistency in truss members’ dimensions, reducing assembly errors.

– Minimizes material waste and enhances overall structural integrity.

Precision Assembly:

– Controlled environments with stable temperature and humidity prevent warping or distortion of truss components.

– Facilitates accurate alignment and secure joint connections.

Quality Control Inspections:

– Regular inspections at every fabrication stage identify and rectify errors, ensuring compliance with design specifications.

– Involves visual inspections, dimensional checks, and load testing to guarantee structural soundness.

Best Practices:

Material Selection:

– Choose high-strength materials like engineered lumber or steel for durability and longevity.

– Consider environmental factors such as moisture and insect resistance to enhance truss performance.

Design Optimization:

– Utilize advanced design software to analyze load distribution and optimize truss geometry for maximum efficiency.

– Employ wind and seismic load calculations to ensure the truss system can withstand local environmental conditions.

Skilled Fabrication:

– Engage experienced fabricators with a proven track record of quality craftsmanship.

– Provide clear fabrication drawings and specifications to ensure precise assembly and timely delivery.

Additional Tips:

- Invest in regular maintenance and inspection of fabrication equipment to maintain accuracy and efficiency.

- Train fabrication personnel on the latest industry standards and best practices.

- Implement continuous improvement initiatives to enhance fabrication processes and product quality.

Relevant URL Sources:

Structural Analysis and Load Considerations

Ensuring Structural Integrity in Roof Truss Design

As you design complex roof truss systems, understanding structural analysis and load considerations is crucial. Here’s a guide to help you navigate these critical aspects:

Structural Analysis

Analyze and verify roof trusses using structural analysis software that considers simply supported conditions and restraints in the Z-axis. This analysis ensures structural soundness and prevents failures.

Section Selection

Choose an initial section for analysis, such as an AISC L shape of size 2.5”x2.5”x3/16”. The shape and dimensions impact the truss’s strength and stability.

Roof Loads

Consider all types of roof loads, including roof sheets, accessories, and self-weight. ASCE 7-16 LRFD Load Combinations guide design decisions to account for various loading scenarios.

Load Generator

Utilize tools like SkyCiv Load Generator to simplify load calculations. It automates wind load estimation, eliminating manual errors.

Key Takeaways:

- Structural analysis is essential to ensure truss stability and prevent failures.

- Section selection influences the truss’s strength and durability.

- Considering all roof loads is crucial for accurate design.

- Load generators simplify load calculations, saving time and reducing mistakes.

Citations:

Truss Erection: A Guide to Safety and Precision

Ensuring the erection of roof truss systems is carried out with the utmost safety and adherence to best practices is a cornerstone of successful construction. This guide delves into the essential steps and principles that contractors must follow to safeguard the integrity of the structure and the well- being of those involved.

Key Takeaways:

- Implement safe working practices to avert occurrences, such as tumbling or an abrupt surrendering of the structure.

- Enforce an all-encompassing comprehension of installation imperatives previous to initiating the method.

- Confirm the accessibility of the necessary blueprints, outlines, and construction recommendations on-site prior to starting installation.

- Execute vigilant examinations for harm, assuring appropriate support and foundations on dividers.

- Utilize the correct gear and devices for lifting and setting up the roof truss.

- Adhere to suitable fastening and support practices.

Pre-Installation Imperatives:

- Familiarize yourself with the construction plan and blueprints.

- Study the truss design to comprehend the load capacities and support requirements.

- Designate a safe working area and arrange for the necessary equipment and materials.

- Conduct a thorough safety briefing with the installation crew, highlighting potential concerns, and fall protection measures.

- Erect barricades and cautionary signs around the installation area.

The Process of Erection:

- Start by lifting the initial truss into its upright position.

- Carefully place the truss on the support walls, guaranteeing that the load is dispersed appropriately.

- Secure the truss to the dividers utilizing appropriate connectors and fasteners.

- Proceed with the installation of extra rafters, adhering to the truss spacing detailed in the blueprints.

- Repeat this method until all the roof frame is assembled.

- Install any extra support elements, like purlins or ridge beams, as needed.

Post-Installation Checks:

- Double-check the plumb and level of each truss, making any essential rectifies immediately.

- Verify the tightness of all bolts, connectors, and fasteners.

- Ensure that the roof sheathing is properly installed and affixed to the rafters.

- Takedown all barricades and warning signs once the installation is complete.

URL Source:

- Work Safety: Truss Erection

By following these steps and adhering to best practices, contractors can ensure that their roof truss erection project is completed with the utmost safety and finesse, providing an enduring and sturdy basis for the superstructure.

FAQ

Q1: What is the importance of precise cuts and controlled assembly in roof truss fabrication?

Q2: How can structural analysis software assist in designing roof trusses?

Q3: What are essential considerations for selecting and specifying appropriate roof trusses?

Q4: What safety precautions should be taken during roof truss installation to prevent accidents?

Q5: What innovative techniques and materials are being used in modern roof truss construction?

- Best Finish for Butcher Block Countertops: Choosing the Right Option - December 30, 2025

- Seal for butcher block: Find the best food-safe finish - December 29, 2025

- Finishes For Butcher Block Counters: Choosing The Right Food-Safe Option - December 28, 2025