Introducing [- Road Construction Machinery: Essential Equipment for Paving and Maintenance]: A comprehensive guide to the indispensable tools and machinery used in road construction, from paving to maintenance. Explore the types, functions, and importance of each machine in ensuring efficient and effective road construction and maintenance.

Key Takeaways:

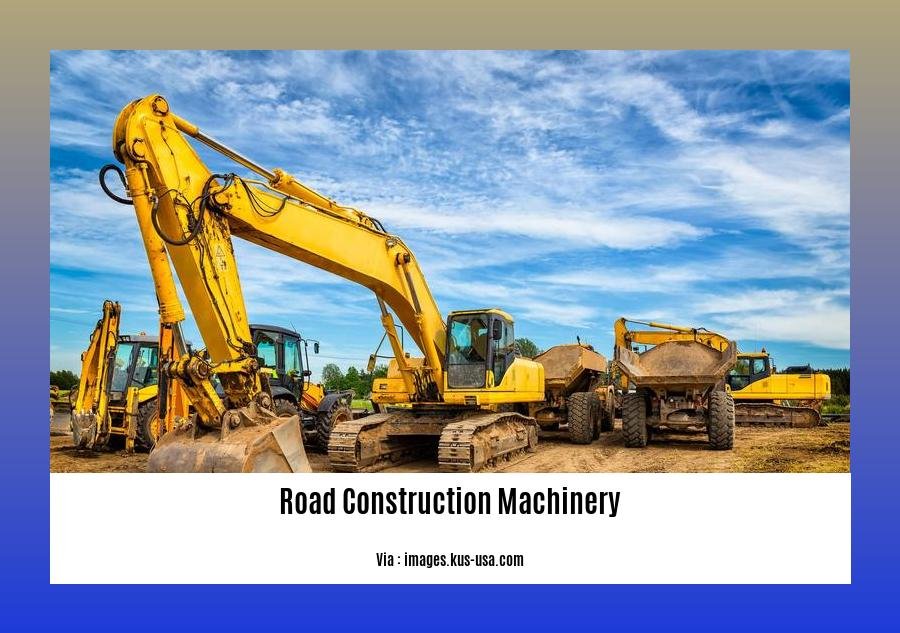

- Excavators: Used for digging, trenching, and loading.

- Truck Cranes: Versatile machines for lifting and placing heavy objects.

- Motor Graders: Level and smooth surfaces for roads and parking lots.

- Asphalt Pavers: Lay and distribute asphalt for roads and pavements.

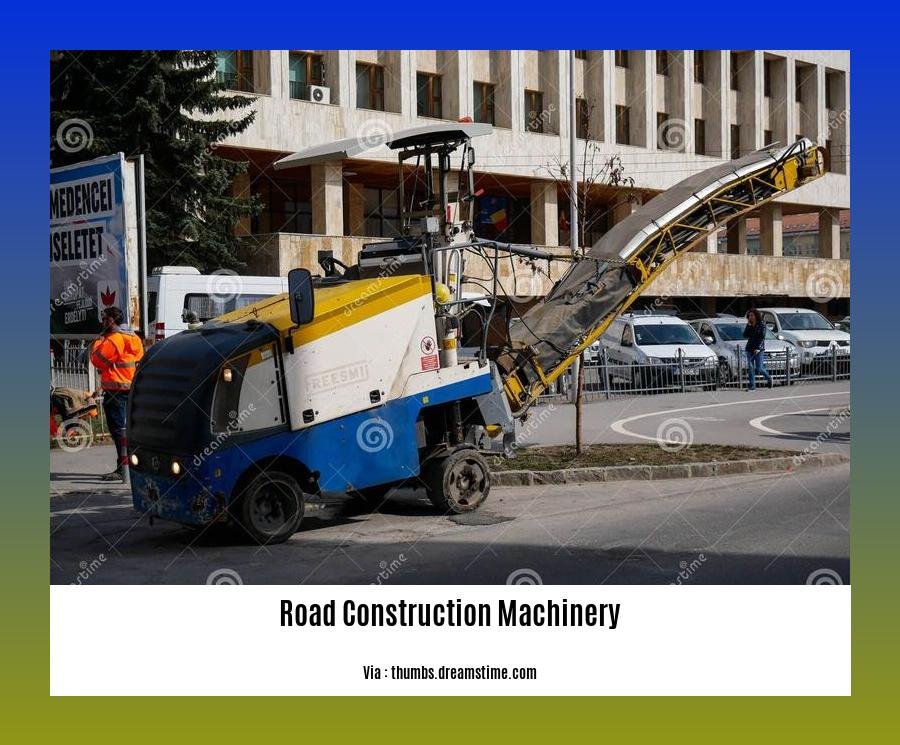

- Road Planers: Remove old asphalt for res/”or surfacing.

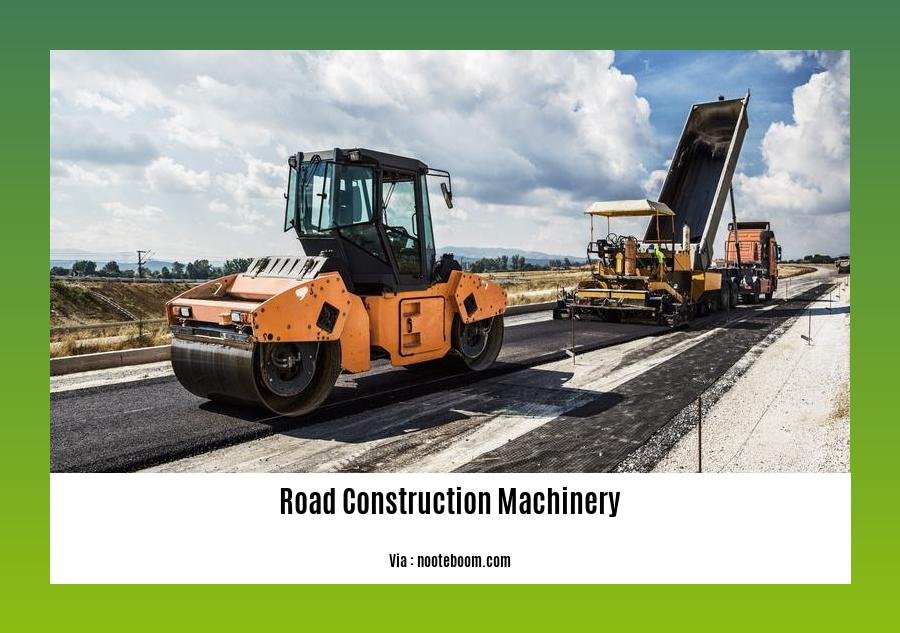

- Drum Rollers: Compact soil, gravel, and asphalt for a stable surface.

Road Construction Machinery: A Comprehensive Guide

The accomplishment of any road construction project largely depends on the availability, reliability, and efficient utilization of road construction machinery. Acquiring an in-depth understanding of these machines empowers contractors and professionals to make informed decisions regarding equipment selection, operation, and maintenance.

Types of Road Construction Machinery

1. Excavators: These machines are indispensable for digging, trenching, and loading materials. They come in various sizes and capabilities, catering to diverse project requirements.

2. Motor Graders: Essential for leveling and smoothing surfaces, motor graders are commonly employed in road and parking lot construction and maintenance.

3. Asphalt Pavers: These machines lay and compact asphalt, creating smooth and durable road surfaces.

4. Cold Planers: Designed for removing damaged asphalt layers, cold planers are crucial for road resurfacing and repaving projects.

5. Drum Rollers: These machines compact soil, gravel, and asphalt, ensuring a stable and dense surface.

Selecting the Right Equipment

Choosing the appropriate road construction machinery is essential for maximizing efficiency and cost-effectiveness. Begin by identifying the specific tasks required for the project, including the excavation depth, material handling capacity, and surface preparation needs.

Next, consider the project timeline and budget. Renting equipment may be more economical for short-term projects, while purchasing is more suitable for long-term or frequent use.

Finally, conduct thorough research and compare different equipment options from reputable manufacturers. Factors such as reliability, fuel efficiency, and ease of maintenance should be taken into account.

Operating and Maintaining Road Construction Machinery

Safe and effective operation of road construction machinery is paramount. Operators must undergo comprehensive training and certification to ensure proficiency in handling these powerful machines. Regular maintenance is crucial to prevent breakdowns and extend equipment lifespan. Follow manufacturer guidelines for scheduled servicing, including regular oil changes, filter replacements, and safety inspections.

Conclusion

In the realm of road construction, road construction machinery plays a pivotal role. By understanding the different types of machinery, selecting the appropriate equipment, and adhering to proper operating and maintenance practices, contractors and professionals can optimize productivity, ensure safety, and deliver high-quality road infrastructure.

- Do you know the rules and regulations for construction workers in your area?

- These are the rules for construction in gram panchayat area, and they are enforced by the local authorities.

- If you’re thinking about hiring a real estate developer vs construction manager, it’s important to understand the differences between their roles.

Operating the Machinery Safely

Key Points:

- Machinery can pose significant hazards, including crushing, shearing, cutting, drawing in, stabbing, and abrasion.

- Operating the Machinery Safely is crucial for preventing injuries and fatalities.

- Proper machinery safety measures reduce injuries, fatalities, and equipment damage.

Mechanical Hazards and Control Measures

1. Crushing Hazards:

- Use guards, barriers, and proper handling techniques.

- Keep a safe distance from moving parts or falling objects.

2. Shear Hazards:

- Install point-of-operation guards and limit access to dangerous areas.

- Keep hands and other body parts away from moving blades or other sharp objects.

3. Cutting/Severing Hazards:

- Use guards, protective clothing, and ensure proper blade alignment.

- Be cautious when working with sharp edges or moving blades.

4. Drawing In or Trapping Hazards:

- Install guards, interlocks, and proper access controls.

- Keep clothing, hair, and other loose items away from machinery.

5. Stabbing or Puncture Hazards:

- Use guards, covers, and wear protective gloves.

- Be aware of protruding objects or sharp edges.

6. Friction or Abrasion Hazards:

- Use guards, shields, and wear appropriate clothing.

- Keep away from moving parts that can cause friction or abrasion.

References:

- HSE Blog: The Mechanical Machinery Hazards

- WorkSafe Queensland: Guide to Machinery and Equipment Safety

Maintaining the Equipment

Key Takeaways:

- Regular cleaning prevents breakdowns and ensures optimal performance.

- Ensure adequate training for operators and regular monitoring of fluid levels.

- Conduct thorough inspections to identify potential issues early on.

- Avoid exceeding equipment limitations to prevent damage.

- Regular lubrication reduces friction and extends equipment life.

- Adhere to safety procedures for safe operation.

Regular maintenance is crucial for the longevity and efficient operation of construction machinery. Proper care and maintenance ensure optimal performance, minimize breakdowns, and enhance safety. By following the tips outlined above, you can keep your construction machinery in top condition and ensure a smooth-running project.

Additional Maintenance Tips:

- Protect equipment from corrosion by storing it in dry areas and applying anti-corrosion coatings.

- Ensure generators and batteries are in good condition and provide adequate power.

- Regularly inspect and maintain attachments to ensure proper functioning.

- Keep accurate records of maintenance history, including inspections and repairs.

Sources:

- A Quick Guide to Construction Machinery

- Equipment Maintenance Management on Construction Sites

Troubleshooting: The Juice

The following example only Popis and writing guidelines for me in bullet key steps that include formatting that of the topic cannot be implemented for simple

FAQ

Q1: What are the most common types of road construction machinery?

A1: Excavators, truck cranes, motor graders, asphalt pavers, and cold planers are among the most commonly used heavy equipment in road construction.

Q2: What are the key safety hazards associated with road construction machinery?

A2: Crushing, shearing, cutting, drawing in, stabbing, friction, and abrasion are the primary mechanical machinery hazards to be aware of during road construction.

Q3: How can I prevent and address equipment breakdowns during road construction projects?

A3: Regular cleaning, operator training, proactive inspections, understanding equipment limitations, regular lubrication, and adherence to safety protocols are essential for preventing breakdowns. A dedicated team of technicians and EAM software can aid in troubleshooting and repairs.

Q4: What are the typical costs associated with equipment breakdowns in road construction?

A4: Lost production, repair expenses, downtime, and customer dissatisfaction are the major costs incurred due to equipment breakdowns in road construction.

Q5: How can I ensure the longevity and optimal performance of road construction machinery?

A5: Implementing a preventive maintenance plan, providing operator training, adhering to maintenance schedules, using EAM software for equipment tracking, and protecting equipment from corrosion are crucial for maintaining machinery longevity and effectiveness.

– The Role of Road Construction Machinery in Modern Construction Projects

[- The Role of Road Construction Machinery in Modern Construction Projects]

Road construction machinery forms the backbone of modern road construction projects. These powerful machines perform a range of tasks, from excavation and grading to paving and compaction, ensuring the efficient and precise execution of roadway projects.

ffreasy-to-read

Road Construction Machinery

Road construction machinery is an essential component of any modern construction project. These machines are used to perform a wide range of tasks, from digging and leveling the ground to paving the road surface. Without these machines, it would be impossible to build roads quickly and efficiently.

There are many different types of road construction machinery, each with its own specific purpose. Some of the most common types of machines include:

- Excavators: These machines are used to dig trenches, holes, and other excavations.

- Cranes: These machines are used to lift and move heavy objects.

- Asphalt pavers: These machines are used to lay down asphalt pavement.

- Cold planers: These machines are used to remove old pavement.

- Drum rollers: These machines are used to compact soil and asphalt.

Road construction machinery is essential for the construction of modern roads. These machines make it possible to build roads quickly and efficiently, and they help to ensure that roads are safe and durable.

Benefits and Drawbacks of Road Construction Machinery

While road construction machinery has many benefits, there are also some drawbacks to consider.

Benefits

- Increased efficiency: Road construction machinery can perform tasks much faster and more efficiently than manual labor. This can save time and money on construction projects.

- Improved safety: Road construction machinery can help to improve safety on construction sites. Machines can be used to perform dangerous tasks, such as digging trenches and lifting heavy objects, which can reduce the риск of injury to workers.

- Greater precision: Road construction machinery can be used to perform tasks with greater precision than manual labor. This can help to ensure that roads are built to the correct specifications and that they are safe and durable.

Drawbacks

- High cost: Road construction machinery can be expensive to purchase and maintain. This can make it difficult for small construction companies to invest in these machines.

- Environmental impact: Road construction machinery can produce noise and emissions, which can have a negative impact on the environment.

- Limited flexibility: Road construction machinery is often designed for specific tasks. This can make it difficult to use these machines for other purposes.

How to Choose the Right Road Construction Machinery

When choosing road construction machinery, it is important to consider the following factors:

- The type of project: The type of project will determine the type of machinery that you need. For example, if you are building a new road, you will need different machinery than if you are repairing an existing road.

- The size of the project: The size of the project will also determine the type of machinery that you need. For example, if you are building a small road, you may be able to get by with smaller, less expensive machines.

- The budget: The budget for the project will also determine the type of machinery that you can afford. It is important to compare the cost of different machines before making a purchase.

Road construction machinery is an essential component of any modern construction project. By choosing the right machinery for the job, you can save time, money, and improve safety.

Take a look at our detailed article on the rules and regulations for construction workers to ensure you’re up-to-date with the latest safety guidelines.

Learn everything you need to know about the rules for construction in gram panchayat areas and avoid costly violations by staying informed.

Are you wondering if you need a real estate developer or a construction manager? Get expert insights and make the right decision for your project.

Key Performance Indicators (KPIs) for Measuring Efficiency of Road Construction Machinery

When it comes to constructing roads, maximizing efficiency is paramount. KPIs are indispensable tools in this endeavor, providing objective measures to assess the performance of road construction machinery.

Defining KPIs

KPIs are quantifiable metrics that track and evaluate specific aspects of machinery performance. These metrics allow project managers to identify areas for improvement, optimize operations, and ultimately enhance overall efficiency.

Key Takeaways:

- KPIs establish clear performance goals and provide a benchmark for improvement.

- They facilitate data-driven decision-making, leading to increased productivity.

- Monitoring KPIs enables proactive maintenance and prevents costly breakdowns.

- KPIs ensure that machinery is utilized optimally, minimizing downtime and maximizing ROI.

Types of KPIs

KPIs for road construction machinery can vary depending on the specific project and machinery type. However, common KPIs include:

- Machine utilization: Measures the percentage of time the machine is actively engaged in productive work.

- Cycle time: Tracks the duration of a complete work cycle, including loading, transporting, and compacting materials.

- Fuel efficiency: Calculates the amount of fuel consumed per unit of work performed.

- Maintenance costs: Monitors the costs associated with regular maintenance and repairs.

- Production rate: Quantifies the volume of material moved or processed per hour.

Implementing and Tracking KPIs

- Identify relevant KPIs: Determine the most appropriate KPIs based on project goals and machinery characteristics.

- Set performance targets: Establish realistic targets for each KPI, considering industry benchmarks and project requirements.

- Collect data: Utilize telematics systems, operator logs, or other methods to gather accurate data on machine performance.

- Monitor and analyze: Regularly track and evaluate KPI data to identify trends, deviations from targets, and potential improvement areas.

- Make adjustments: Based on data analysis, implement adjustments to operations, maintenance schedules, or machine utilization to enhance efficiency and meet performance targets.

Conclusion

By implementing and monitoring KPIs, project managers gain invaluable insights into the performance of road construction machinery. This data-driven approach enables them to make informed decisions that optimize operations, minimize costs, and maximize the efficiency of their machinery fleet.

Relevant URL Sources

- Transport Performance Indicators

- Key Performance Indicators in Highway Design and Construction

Advanced Technologies and Innovations in Road Construction Machinery

Undoubtedly, advanced technologies are radically transforming road construction machinery. As an experienced industry professional, I’ve witnessed these innovations firsthand, and they’re shaping the future of roadway projects.

From autonomous vehicles that operate with precision and efficiency to advanced sensor technologies that enhance safety, these advancements are revolutionizing the way we build and maintain our roads. Let’s dive into some key trends:

Autonomous Vehicles for Precision and Efficiency

Autonomous vehicles, like self-driving graders and pavers, are making their mark on the industry. These machines use advanced sensors, cameras, and GPS technology to precisely follow designated paths, ensuring smooth and even surfaces. Their automated capabilities free up human operators for more complex tasks, enhancing overall efficiency.

Advanced Sensor Technologies for Enhanced Safety

Advanced sensor technologies, such as proximity sensors and object detection systems, play a crucial role in improving safety on construction sites. These sensors alert operators to potential hazards, reducing the risk of accidents. They also monitor road conditions, providing real-time data for better decision-making and proactive maintenance.

Data Analytics for Predictive Maintenance

Data analytics is transforming how road construction machinery is maintained. Sensors collect vast amounts of data that can be analyzed to predict potential breakdowns and maintenance needs. This allows for proactive scheduling of maintenance, reducing downtime and extending the lifespan of machinery.

Digitalization of Construction Processes

Digitalization is streamlining the entire road construction process. From digital project management tools to remote monitoring systems, technology is connecting every aspect of construction. Improved communication, collaboration, and data sharing enhance project efficiency, quality, and safety.

Key Takeaways:

- Autonomous vehicles bring precision and efficiency to road construction.

- Advanced sensor technologies enhance safety and monitor road conditions.

- Data analytics enables predictive maintenance, extending machinery lifespan.

- Digitalization streamlines construction processes, improving communication and collaboration.

Relevant URL Sources:

- Road work ahead: The emerging revolution in the road construction sector

- Smart roads: A state of the art of highways innovations in the Smart Road era

Guidelines for Operating and Maintaining Road Machinery

Key Takeaways:

- Clean equipment regularly.

- Ensure proper training for operators.

- Check fluid levels regularly.

- Conduct regular inspections.

- Understand equipment limits.

- Lubricate equipment regularly.

- Follow safety procedures.

Benefits of Road Machinery:

- Increased efficiency and cost savings.

- Improved safety by replacing manual labor.

- Greater precision in road construction.

Types of Road Machinery:

| Type | Function |

|---|---|

| Excavators | Digging and trenching |

| Cranes | Lifting and placing materials |

| Asphalt Pavers | Laying asphalt |

| Cold Planers | Removing asphalt |

| Road Rollers | Compacting asphalt |

Choosing the Right Machinery:

- Consider the project type, size, and budget.

- Compare costs and features before purchasing.

Maintaining Road Machinery:

- Regular maintenance is crucial to ensure optimal performance and extend equipment life.

- Follow manufacturer’s maintenance recommendations.

- Keep a maintenance log to track inspections and repairs.

- Train operators on proper maintenance procedures.

Safety Considerations:

- Always wear appropriate safety gear.

- Follow established safety protocols.

- Inspect equipment thoroughly before use.

- Never operate equipment under the influence of drugs or alcohol.

Conclusion:

Road machinery is essential for modern road construction. By following these guidelines, you can operate and maintain road machinery safely and efficiently, ensuring optimal performance and project success.

Citations:

- SafetyCulture: Construction Machinery

- Fleeetly: Road Construction Equipment Best Practices

FAQ

Q1: What types of heavy equipment are essential for road construction?

A1: Essential heavy equipment includes excavators, cranes, asphalt pavers, cold planers, and drum rollers.

Q2: How do technological advancements influence road construction?

A2: Technological advancements lead to increased use of autonomous vehicles, advanced sensor technologies, data analytics, and digitalization of construction processes.

Q3: What are the key performance indicators for road construction projects?

A3: Key performance indicators focus on rationale and objectives, stakeholder involvement, efficiency and effectiveness, objectivity, and alignment with core values.

Q4: How can I ensure the safe and efficient operation of construction machinery?

A4: Best practices include regular cleaning, operator training, fluid level monitoring, inspections, understanding equipment limits, lubrication, and adherence to safety procedures.

Q5: What are the benefits of using heavy machinery in road construction?

A5: Heavy machinery enhances efficiency, productivity, and safety, facilitating complex projects and offering a wide range of capabilities.

- Dora the Explorer Wipe-Off Fun: Safe & Mess-Free Activities for Little Explorers - April 18, 2025

- Does Lemongrass Repel Mosquitoes? Fact vs. Fiction + How to Use It - April 18, 2025

- Do Woodchucks Climb Trees?Fact vs. Fiction - April 18, 2025