Step into the world of AAC block construction with our comprehensive guide, [- Architectural Design and Construction with AAC Blocks: A Comprehensive Guide to AAC Block Construction Details]. Discover the intricacies of AAC block properties, installation techniques, and design considerations, empowering you to harness the full potential of this innovative building material. Unlock the secrets of AAC block construction and elevate your architectural marvels to new heights of efficiency, sustainability, and structural integrity.

Key Takeaways:

-

Autoclaved aerated concrete (AAC) blocks are a type of concrete that is made from a mixture of cement, lime, silica sand, and aluminum powder.

-

AAC blocks are a sustainable construction material because they are lightweight, porous, and have good thermal and acoustic insulation properties.

-

AAC blocks are relatively easy to install both for interior and exterior walls compared to other materials used in construction.

-

AAC blocks also are a cost-effective and environmentally friendly building material.

-

The manufacturing process involves raw material preparation, mixing, casting, and curing.

AAC Block Construction Details

Hello there, everyone! Welcome to our comprehensive guide on AAC block construction details. In this article, we’ll delve into the intricacies of AAC block construction details, providing valuable insights for architects, builders, and homeowners alike seeking sustainable and efficient building solutions.

What are AAC Blocks?

AAC blocks, short for autoclaved aerated concrete blocks, are a revolutionary building material made from a mixture of cement, lime, silica sand, and aluminum powder. These lightweight and porous blocks boast exceptional thermal and acoustic insulation properties, making them a preferred choice for sustainable and energy-efficient construction.

Benefits of Using AAC Blocks:

Choosing AAC blocks for your construction project offers several advantages, including:

-

Lightweight and Easy to Handle: AAC blocks are significantly lighter than traditional concrete blocks, making them easier to transport, install, and work with. This characteristic also reduces the structural load on the building.

-

Superior Insulation: The cellular structure of AAC blocks provides excellent thermal insulation, helping maintain comfortable indoor temperatures year-round. This translates to reduced energy consumption and lower utility bills.

-

Acoustic Insulation: AAC blocks also possess remarkable soundproofing qualities, effectively absorbing and dampening noise, making them ideal for residential, commercial, and industrial applications.

-

Fire Resistance: AAC blocks exhibit exceptional fire resistance, withstanding high temperatures for extended durations without losing their structural integrity. This characteristic enhances the safety and resilience of buildings.

-

Sustainability: AAC blocks are a sustainable building material, primarily composed of natural and recycled materials. Their production process has a lower environmental impact compared to traditional concrete, contributing to greener construction practices.

AAC Block Construction Process:

For successful AAC block construction, follow these steps:

-

Foundation Preparation: Ensure a solid and level foundation to support the AAC block structure.

-

Mortar Selection: Choose an appropriate mortar specifically designed for AAC blocks.

-

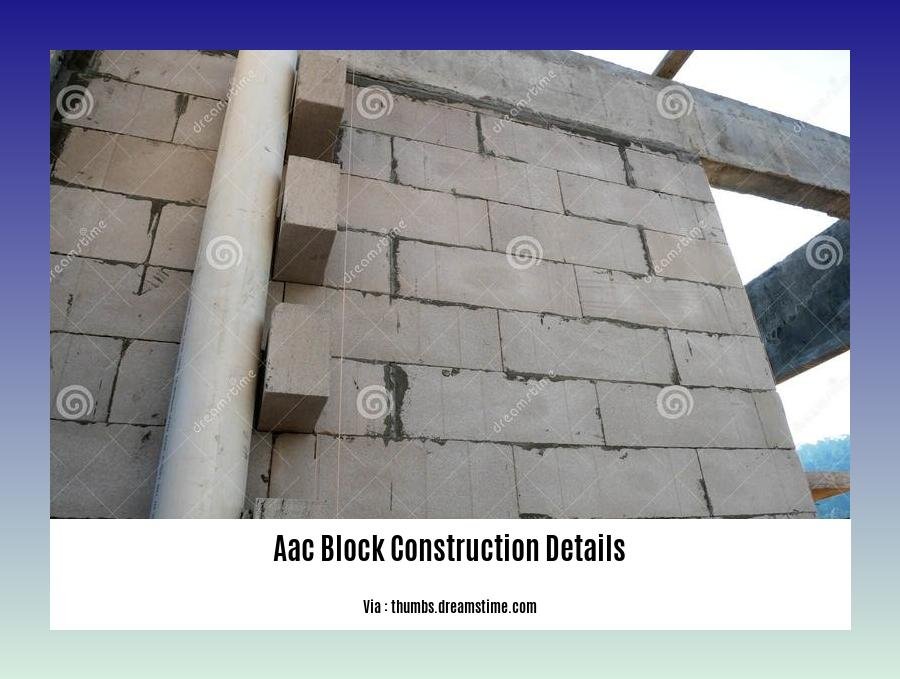

Laying the First Course: Begin by laying the first course of AAC blocks on the foundation, ensuring proper alignment and level.

-

Applying Mortar: Apply a thin layer of mortar to the vertical and horizontal faces of each AAC block before placing the next block.

-

Interlocking Blocks: Stagger the joints between adjacent blocks to enhance structural stability.

-

Reinforcement: Incorporate steel reinforcement as required by structural calculations to withstand loads and improve the overall strength of the structure.

-

Curing: Allow the mortar to cure properly, following the manufacturer’s guidelines, before applying any finishes or loads.

Conclusion:

With their remarkable properties and construction advantages, AAC blocks are transforming the construction industry. Their lightweight nature, superior insulation, acoustic performance, fire resistance, and sustainability make them a compelling choice for architects, builders, and homeowners seeking durable and eco-friendly building solutions. By mastering AAC block construction details, you can create energy-efficient and comfortable structures that align with modern construction standards. If you have any questions or require further guidance, feel free to leave a comment below, and I’ll be happy to assist you.

- To learn more about the 3D printing construction companies in India, click here.

- To get insights into the cost of 4.5 inch brick wall construction, check this.

- To find out the cost of 9 inch brick wall construction in India, click here.

AAC Block Installation Techniques: Explore various installation techniques for AAC blocks, including adhesive bonding, mortar bonding, and dry stacking methods, considering factors such as structural stability and weather conditions.

Before we dive into the fascinating world of AAC block installation techniques, let me unveil some key takeaways:

Key Takeaways:

-

AAC blocks, composed of cement, lime, silica sand, and aluminum powder, boast numerous advantages, including lightweight properties, exceptional insulation capabilities, fire resistance, and eco-friendliness.

-

AAC block construction involves meticulous preparation, from selecting appropriate mortar to laying the first course, applying mortar, and allowing proper curing.

-

Adhesive bonding, mortar bonding, and dry stacking are the primary installation methods for AAC blocks. Each technique offers unique advantages and considerations.

Installation Techniques:

Now, let’s embark on a journey through the three primary installation techniques for AAC blocks, unveiling their nuances and suitability for various projects:

Adhesive Bonding:

– This method utilizes pre-mixed AAC block adhesive, ensuring a thin, consistent layer between blocks. It excels in enhancing thermal insulation and minimizing mortar usage.

– Fortified with cement, graded sand, and admixtures, the adhesive forms a strong bond, eliminating the need for conventional cement or stone mortar joints.

Mortar Bonding:

– This traditional technique involves using a mortar mix specifically designed for AAC blocks. It provides excellent structural stability and is suitable for load-bearing walls.

– Mortar bonding offers flexibility in adjusting block positions and accommodates minor irregularities in block dimensions. However, it requires more time and effort compared to adhesive bonding.

Dry Stacking:

– This innovative method involves stacking AAC blocks without any adhesive or mortar. It relies on the precise cutting and interlocking of blocks, creating a friction-based bond.

– Dry stacking offers exceptional speed and ease of installation, reducing construction time and labor costs. However, it may require specialized equipment and expertise.

Factors to Consider:

Beyond the installation techniques, let’s explore the crucial factors that influence the selection of the most suitable method:

Structural Stability:

– The intended use of the structure plays a pivotal role in determining the appropriate installation technique. Load-bearing walls, for instance, require a strong and stable bonding method like mortar bonding.

Weather Conditions:

– Weather conditions can significantly impact the installation process. In regions with extreme temperatures or high humidity, adhesive bonding may be preferred, as it minimizes the risk of moisture absorption and thermal expansion.

Budget and Timeline:

– Cost and time are practical considerations that can influence the choice of installation technique. Dry stacking, for example, can expedite the construction process, potentially reducing overall costs.

For a comprehensive understanding of AAC block installation techniques, I highly recommend exploring these credible sources:

1. AAC Blocks Installation: A Complete Guideline

2. How to Install the AAC Blocks?

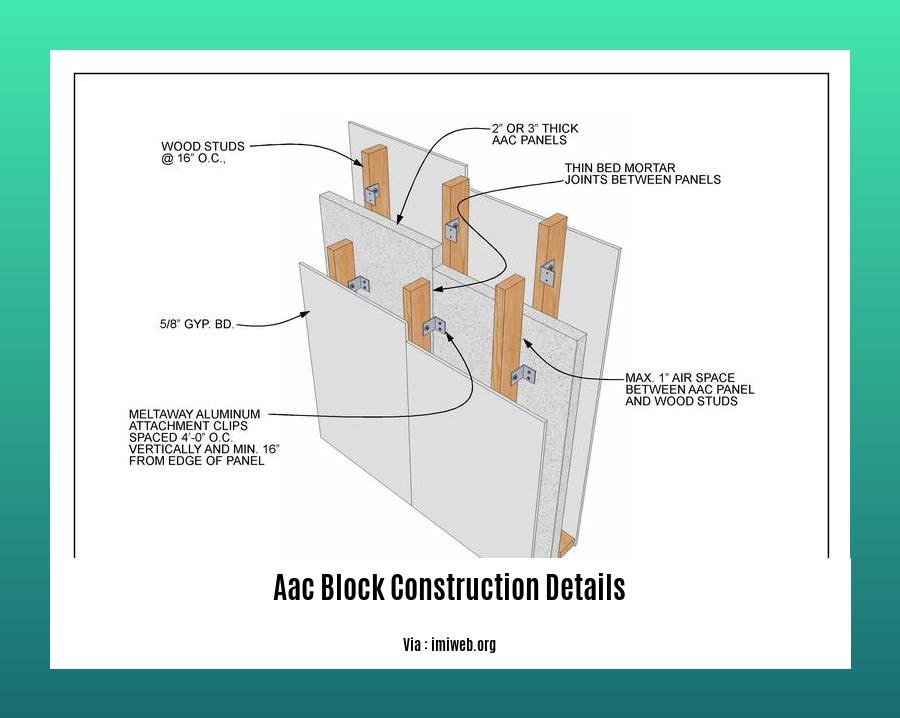

Reinforcement and Connection Details: Discover reinforcement techniques for AAC block construction, including the use of steel reinforcement bars, wire mesh, and connectors, as well as proper connection methods between AAC blocks and other building elements.

Hey there, construction enthusiasts! In this section, we’re diving deep into the fascinating world of reinforcement and connection details in AAC block construction. From steel reinforcement bars to wire mesh and connectors, we’ll uncover the techniques that ensure the structural integrity and durability of AAC block buildings.

Key Takeaways:

- AAC blocks: Lightweight and energy-efficient construction material with superior insulation properties.

- Reinforcement: Crucial for enhancing the strength and stability of AAC block structures.

- Steel reinforcement bars: Provide tensile strength to resist bending and cracking.

- Wire mesh: Used for reinforcing AAC blocks in areas subjected to lateral forces.

- Connectors: Join AAC blocks to other building elements like concrete slabs and steel beams.

- Proper connection methods: Ensure efficient load transfer and prevent structural failure.

Now, let’s delve into the details of each reinforcement and connection technique:

1. Steel Reinforcement Bars:

– These bars are embedded within AAC blocks to provide tensile strength and resist bending forces.

– They’re commonly used in lintels, beams, columns, and other structural elements.

– The size and spacing of the bars depend on the design requirements and structural loads.

2. Wire Mesh:

– Wire mesh is a grid-like material made from steel wires welded together.

– It’s placed between layers of AAC blocks to enhance resistance to lateral forces like wind and earthquakes.

– Wire mesh also helps distribute loads evenly and prevent cracking.

3. Connectors:

– AAC blocks are joined to other building elements like concrete slabs and steel beams using various types of connectors.

– These connectors can be mechanical (bolts, screws) or adhesive (epoxy resins).

– Proper selection and installation of connectors are essential for ensuring structural stability.

4. Proper Connection Methods:

– The connection between AAC blocks and other building elements must be carefully executed to ensure efficient load transfer and prevent structural failure.

– Common connection methods include mortared joints, dry joints, and mechanical connections.

– The choice of connection method depends on the specific structural requirements and design considerations.

By understanding these reinforcement and connection details, you’ll be able to construct robust and durable AAC block structures that can withstand various loads and environmental conditions.

Most Relevant URL Sources:

– AAC Block Construction Details

– Reinforcement and Connection Details in AAC Block Construction

Quality Control and Testing: Ensure the quality and integrity of AAC block construction by implementing effective quality control measures, including visual inspections, material testing, and compliance with industry standards and regulations.

In AAC block construction, quality control is paramount to ensure the integrity and longevity of the structure. Here are crucial steps to implement effective quality control measures:

Visual Inspection:

Consistently examine AAC blocks for physical defects, such as cracks, chips, discoloration, or irregular shapes. Inspect the blocks’ surfaces, edges, and corners thoroughly, ensuring they meet the required specifications.

Material Testing:

-

Compressive strength: Test AAC blocks to determine their load-bearing capacity. This ensures they can withstand the anticipated loads without compromising structural integrity.

-

Density: Measure the density of AAC blocks to verify that they meet the specified range. Density directly relates to the block’s strength and durability.

-

Sound Insulation: Assess the sound insulation properties of AAC blocks to ensure they comply with the desired noise reduction levels. This is particularly important for constructions requiring high levels of soundproofing.

-

Fire Resistance: Evaluate the fire resistance of AAC blocks by conducting fire tests. Ensure they meet the required fire safety standards and provide adequate protection against fire hazards.

Compliance with Standards and Regulations:

Strictly adhere to industry standards and regulations governing AAC block construction. This includes following guidelines for block production, installation, and overall construction practices. Compliance ensures the structure meets the required safety, performance, and sustainability criteria.

Key Takeaways:

-

Quality Control: Implementing rigorous quality control measures is crucial for ensuring the quality and integrity of AAC block construction.

-

Visual Inspection: Regularly inspecting AAC blocks for physical defects helps prevent the use of damaged or non-conforming blocks.

-

Material Testing: Conducting material tests, including compressive strength, density, sound insulation, and fire resistance, verifies that the blocks meet the required performance criteria.

-

Compliance: Adhering to industry standards and regulations ensures the construction meets all safety, performance, and sustainability requirements.

Citations:

FAQ

Q1: What are the advantages of using AAC blocks in construction?

A1: AAC blocks offer numerous advantages, including lightweight properties, superior insulation, faster construction time, improved fire resistance, and contributions to sustainable building practices.

Q2: What is the composition and manufacturing process of AAC blocks?

A2: AAC blocks are crafted from a mixture of cement, lime, silica sand, and aluminum powder. The production involves raw material preparation, mixing, casting, and curing stages to create lightweight, porous, and thermally insulating blocks.

Q3: How are AAC blocks installed in construction projects?

A3: AAC block installation involves preparing a level foundation, cutting the blocks as needed, applying a customized adhesive rather than traditional mortar, laying the blocks in alignment, and allowing curing time for cement mortar joints.

Q4: Is AAC block construction suitable for earthquake-prone areas?

A4: AAC blocks are often chosen for constructions in earthquake-prone regions due to their lightweight and energy-efficient properties, which help ensure structural resilience during seismic events.

Q5: What quality control measures are essential for ensuring the quality of AAC blocks?

A5: Quality control measures for AAC blocks typically include visual inspection for defects, evaluation of compressive strength, assessment of density to meet project specifications, and verification of sound insulation properties to guarantee desired noise reduction levels.

- Dent and Ding Appliances: Find Discounted Appliances Near You - April 15, 2025

- How Much Does It Cost to Replace a Dishwasher in 2024? (A Complete Guide) - April 15, 2025

- Drano vs. Liquid-Plumr: Which Drain Cleaner Works Best in 2024? - April 14, 2025