Delve into the world of innovative building materials with our comprehensive guide to AAC blocks. Discover the advantages and disadvantages of AAC blocks, gaining in-depth insights into their technical details and practical applications. Whether you’re an architect, engineer, or homeowner, this guide will provide you with the essential information you need to make informed decisions about using AAC blocks in your construction projects.

Key Takeaways:

- AAC blocks are precast, super heat, fire, and sound-resistant building materials.

- They arelightweight, extremely workable, and can be extruded into a variety of complex and beautiful architectural elements.

- AAC blocks are 50% less heavy, fire-resistant, energy-optimized, temperature-controlled, and have low water retention.

- They are best used as non-load-bearing sections due to their less forcible force.

AAC Blocks Details: Innovative Building Blocks for Modern Construction

What are AAC Blocks?

AAC blocks (Autoclaved Aerated Concrete) are a lightweight, versatile building material made from a combination of quartz sand, calcined gypsum, lime, portland cement, water, and aluminum powder. The unique manufacturing process involves autoclaving the concrete under high heat and pressure, resulting in a material with exceptional properties:

Benefits of AAC Blocks:

-

Lightweight: AAC blocks are roughly 50% lighter than traditional red bricks, making them easier to handle and reducing the load on foundations.

-

Fire Resistance: AAC’s cellular structure gives it excellent fire resistance, making it ideal for fire-rated partitions and other fire-resistant applications.

-

Sound Insulation: The air-filled cells in AAC blocks provide superior sound insulation, creating a quieter living environment.

-

Energy Efficiency: AAC’s low thermal conductivity helps regulate indoor temperatures, reducing energy consumption for heating and cooling.

-

Workability: AAC blocks can be easily cut, drilled, and shaped, making them adaptable to various designs and architectural features.

Applications of AAC Blocks:

AAC blocks are primarily used for non-load-bearing elements in construction, such as:

- Interior and exterior walls

- Partition walls

- Internal walls for apartments and offices

- Insulation under floors and roofs

Considerations for Using AAC Blocks:

Due to their lower compressive strength compared to traditional concrete blocks, AAC blocks are not suitable for load-bearing applications. Additionally, they require specialized adhesives and mortars for optimal performance.

Conclusion:

AAC blocks are an innovative and sustainable building material that offers a range of benefits for modern construction. Their lightweight, fire resistance, sound insulation, and energy efficiency make them an excellent choice for a variety of applications, contributing to greener and more comfortable buildings.

Discover the pros and cons of advantages and disadvantages of modular construction, a popular construction method transforming the industry.

Explore the key factors to consider when deciding between advantages and disadvantages of prefabrication and traditional construction methods.

Learn about the strengths and weaknesses of advantages and disadvantages of steel frame construction, a durable and adaptable construction system.

Gain insights into the advantages and disadvantages of timber frame construction, a sustainable and versatile building approach.

Aac Blocks Details Pdf

Autoclaved Aerated Concrete (AAC) blocks are a revolutionary construction material that offers exceptional benefits. These lightweight and cellular blocks are composed of fly ash, lime, cement, and an aerating agent, resulting in a unique combination of properties.

Key Takeaways:

- AAC blocks are lightweight, with a density ranging from 25 to 50 lb/ft3.

- They possess excellent thermal insulation properties due to their high porosity.

- AAC blocks come in various sizes, with nominal face dimensions of 8″ x 24″ and thicknesses ranging from 2″ to 16″.

- They exhibit compressive strengths varying from 290 psi to 1090 psi, making them suitable for both load-bearing and non-load-bearing applications.

- AAC blocks are widely used in construction as an environmentally friendly alternative to traditional bricks, providing improved energy efficiency, fire resistance, and acoustic insulation.

Specifications and Properties

AAC blocks are manufactured through a unique production process involving a reaction between aluminum powder and a mixture of lime, cement, fly ash, or sand. This reaction creates a cellular structure within the concrete, resulting in its lightweight and insulating properties.

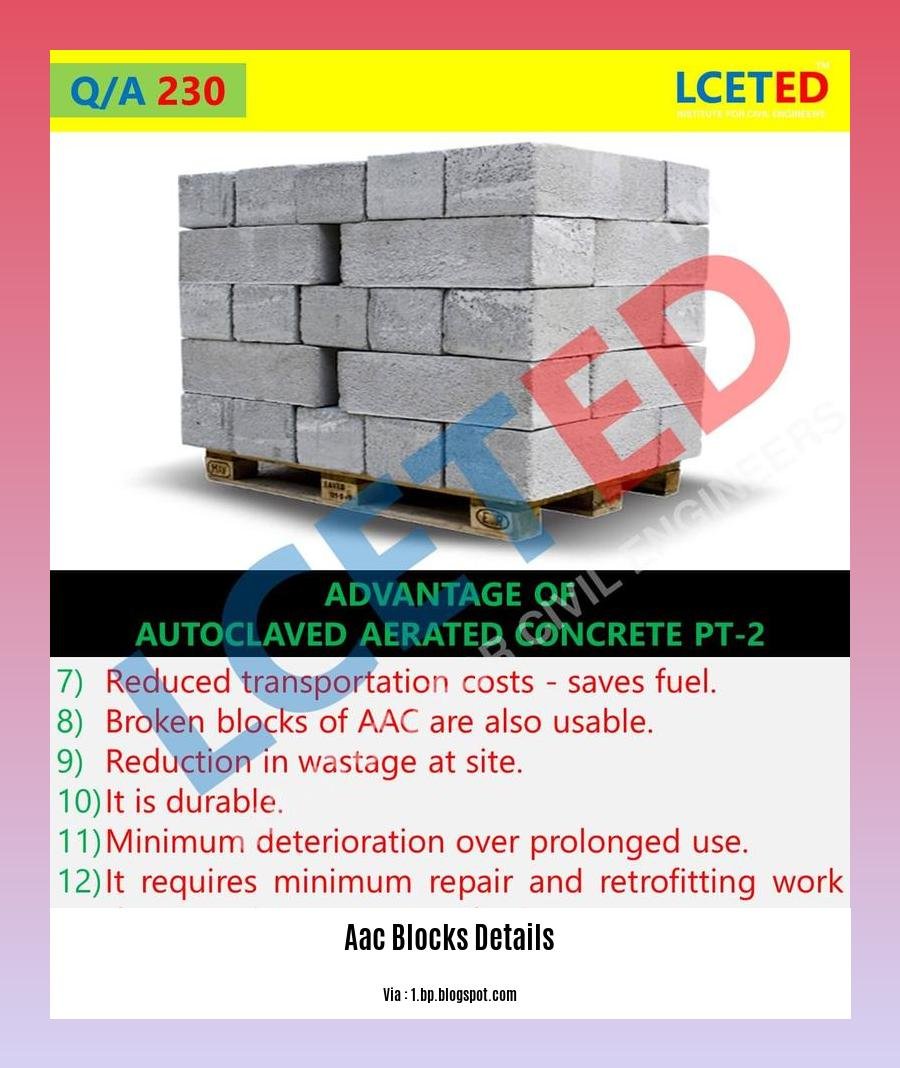

Advantages of AAC Blocks:

- Lightweight: Significantly lighter than traditional bricks, making handling and transportation easier.

- Thermal Insulation: Excellent thermal insulation properties due to their high porosity, reducing energy consumption for heating and cooling.

- Fire Resistance: Inherent fire resistance properties, providing added safety in case of fire.

- Acoustic Insulation: Effective acoustic insulation, reducing noise transmission in buildings.

- Environmental Sustainability: Eco-friendly alternative to traditional bricks, utilizing industrial by-products like fly ash.

Applications of AAC Blocks:

- Residential and commercial buildings

- Load-bearing and non-load-bearing walls

- Partition walls

- Exterior walls

More Information

For more detailed information on AAC blocks, refer to the following resources:

- ResearchGate: Analysis of Autoclaved Aerated Concrete (AAC) Blocks with Reference to the Environmental and Economic Aspects

- International Masonry Institute: AUTOCLAVED AERATED CONCRETE MASONRY UNITS

FAQ

Q1: What are the key advantages of using AAC blocks in construction?

A1: AAC blocks offer numerous advantages, including superior heat, fire, and sound resistance, exceptional lightweight, enhanced workability and flexibility, and remarkable durability.

Q2: How are AAC blocks manufactured?

A2: AAC blocks are produced through a unique process involving autoclaving. The concrete mixture, composed of quartz sand, calcined gypsum, lime, portland cement, water, and aluminum powder, is autoclaved under heat and pressure, resulting in its distinctive properties.

Q3: What are the primary applications of AAC blocks in construction?

A3: Due to their low compressive strength, AAC blocks are primarily used for non-load-bearing elements such as partition walls. However, advancements in production techniques have enabled the development of AAC blocks with higher compressive strengths, expanding their potential applications.

Q4: How do AAC blocks compare to traditional red bricks in terms of weight and performance?

A4: AAC blocks are approximately 50% lighter than red bricks, offering significant weight reduction in construction projects. Moreover, AAC blocks exhibit superior fire resistance, energy optimization, temperature efficiency, and lower water absorption compared to red bricks.

Q5: What are some of the challenges associated with using AAC blocks?

A5: While AAC blocks offer numerous advantages, they also have certain challenges. Their low compressive strength limits their use in load-bearing applications, and their relatively high cost and specialized installation requirements can be factors to consider.

- Does 100% Polyester Shrink? A Complete Guide to Washing & Drying - April 16, 2025

- Elegant Drapery Solutions for Arched Windows: A Complete Guide - April 16, 2025

- The Best Dining Room Tables with Drop Leaves: A Buyer’s Guide - April 16, 2025