Say goodbye to unwanted noise! In this easy-to-follow guide, we’ll show you how to use acoustic sealant like a pro. Get ready to make your home or office a quiet haven. It’s time to soundproof your space!

Understanding Acoustic Sealant

Want to transform your space into a peaceful oasis? Acoustic sealant might be your secret weapon. This specialized sealant combats sound transmission, converting noisy vibrations into negligible heat energy. Let’s explore how it works and how you can use it effectively.

What is Acoustic Sealant?

Acoustic sealant, available in both liquid and foam forms, acts as a sound-absorbing barrier. Typically water-based, it’s easy to clean and generally non-toxic and non-flammable, making it safe for home use. This versatile material adheres to various surfaces like wood, metal, and drywall, effectively filling gaps and cracks that allow sound to infiltrate.

Why Consider Acoustic Sealant?

Acoustic sealant offers numerous benefits beyond simple noise reduction:

- Noise Reduction: Significantly reduces noise pollution for a quieter environment.

- Enhanced Sound Quality: Minimizes echoes and reverberations for a cleaner soundscape, ideal for home theaters or studios.

- Potential Fire Resistance: Some acoustic sealants offer added fire resistance (always check the manufacturer’s information).

- Weatherproofing Capabilities: Can protect against drafts, moisture, and insects, improving comfort and energy efficiency.

- Improved Energy Efficiency: Sealing air leaks enhances insulation, potentially lowering energy bills.

Where Can You Use Acoustic Sealant?

Acoustic sealant is surprisingly versatile:

- General Soundproofing: Reduces noise between rooms, dampens outside sounds, and improves room acoustics. Are you looking for a beanbag chair that’s big enough for adults? We’ve got you covered with our adult beanbag chair 5 ft that’s perfect for relaxing or watching movies in your newly soundproofed space.

- Sealing Air Leaks: Addresses drafts and air leaks, contributing to soundproofing and energy efficiency.

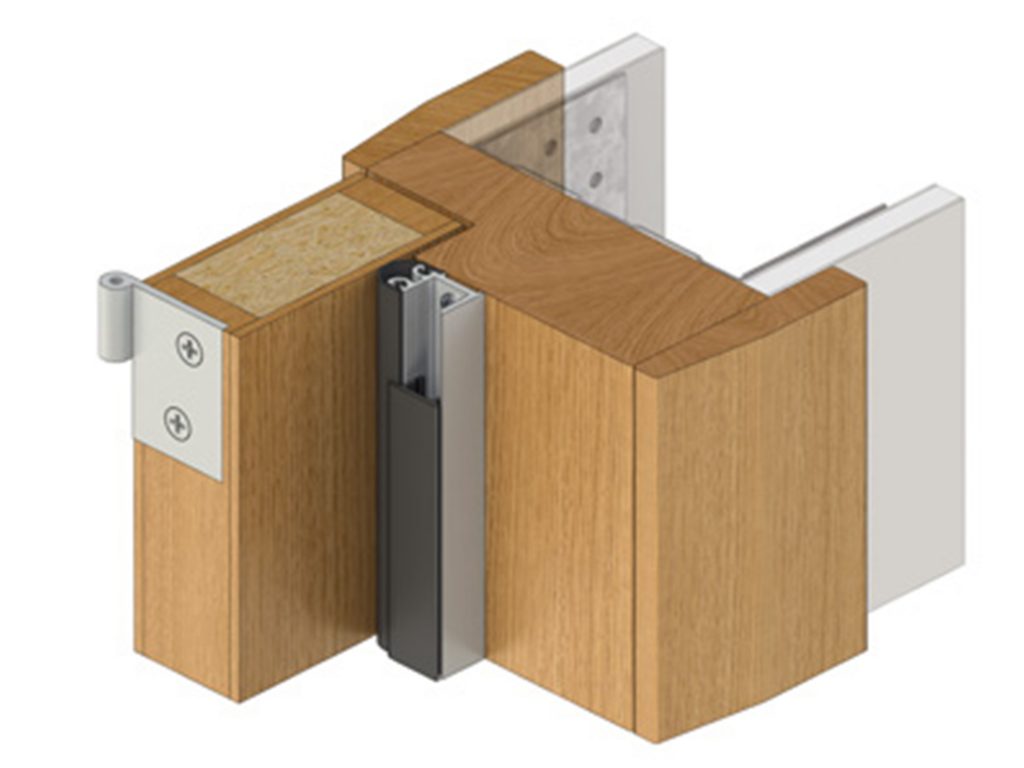

- Construction and Renovation: Essential for sealing around windows, doors, pipes, ductwork, electrical outlets, and wall joints. Declutter your closet and make it more organized with our adjustable closet panels and further enhance your renovation project.

Choosing the Right Sealant

Selecting the right acoustic sealant involves considering a few key factors:

- Base Material: Options include water-based, solvent-based, and silicone, each with its own properties. Water-based is generally easiest to use, solvent-based may be more durable, and silicone offers flexibility and temperature resistance.

- Application Method: Choose between caulk gun, spray can, or brush application based on your project and comfort level.

- Specific Properties: Consider additional needs like fire-rating, paintability, or weatherproofing.

Applying Acoustic Sealant: A Step-by-Step Guide

- Prepare the Surface: Clean and dry the surfaces thoroughly for optimal adhesion.

- Apply the Sealant: Apply a continuous bead, ensuring full coverage of gaps and cracks.

- Smooth the Sealant: Use a wet finger or a smoothing tool for a neat finish.

- Cleanup: Remove excess sealant immediately with a damp cloth or scraper.

Does Acoustic Sealant Really Work?

Acoustic sealant can significantly reduce unwanted noise, especially when used correctly. While it won’t magically create perfect silence, it’s a valuable tool for a quieter environment. It works by blocking airborne sounds and dampening vibrations, unlike standard caulk which can harden and crack, losing its effectiveness over time.

How Does it Work?

Sound travels as waves, causing vibrations upon hitting surfaces. These vibrations travel through your house’s structure. Acoustic sealant plugs the gaps and cracks that these sound waves exploit, disrupting their journey and minimizing noise.

Where to Use Acoustic Sealant

Maximize effectiveness by applying acoustic sealant in key areas:

- Windows and Doors: Seal gaps around frames to minimize outside noise.

- Walls and Ceilings: Seal cracks and joints to improve sound insulation.

- Pipes and Ducts: Reduce noise and vibration transmission.

- Electrical Outlets: Seal around outlets to prevent sound transfer between rooms.

Applying Acoustic Sealant: A Step-by-Step Guide

- Clean the Surface: Wash surfaces with mild soap and water, and allow to dry completely.

- Apply the Sealant: Use a caulking gun to apply a continuous bead, filling the gap entirely.

- Smooth the Bead: Smooth with a putty knife or gloved finger for good surface contact.

- Drying Time: Follow manufacturer instructions for drying time.

Is it a Good Investment?

Acoustic sealant is a cost-effective DIY solution compared to professional soundproofing. Combining it with other strategies like sound-dampening curtains or rugs maximizes noise reduction.

Combining Strategies

Acoustic sealant works best as part of a layered approach. Ongoing research suggests new materials and techniques are continuously evolving the field of soundproofing.

Important Considerations

Effectiveness varies depending on gap size, your space’s construction, and noise type. While reducing noise considerably, complete elimination is unlikely.

| Feature | Acoustic Sealant | Professional Soundproofing |

|---|---|---|

| Cost | Low | High |

| Installation | DIY-friendly | Requires Expertise |

| Effectiveness | Moderate to high for specific noise issues | Potentially higher, broader range |

| Longevity | Dependent on conditions | Potentially longer-lasting |

Acoustic Sealant vs. Silicone: Which is Right for You?

When it comes to soundproofing, acoustic sealant is generally the superior choice. Think of it as the performance vehicle compared to silicone’s standard model. Both seal, but acoustic sealant is engineered for lasting soundproofing.

Key Differences

One major advantage is acoustic sealant’s flexibility, maintaining an airtight seal over time. Silicone tends to harden, crack, and compromise soundproofing efforts.

They also tackle sound differently. Silicone primarily acts as an air barrier, while acoustic sealant is designed to absorb vibrations, providing superior noise reduction, particularly for those pervasive low-frequency sounds. Research suggests some acoustic sealants even dissipate sound energy as heat.

Adhesion is another key differentiator. Acoustic sealant adheres strongly to various building materials, minimizing sound leakage. Silicone can be more selective, impacting effectiveness. While research continues to explore adhesive technologies, acoustic sealant currently holds an edge.

Finally, some acoustic sealants are fire-retardant, meeting standards like ASTM E-84, an advantage over standard silicone.

| Feature | Acoustic Sealant | Silicone Sealant |

|---|---|---|

| Flexibility | Remains flexible | Hardens and may crack |

| Sound Dampening | Absorbs vibrations | Primarily blocks airflow |

| Adhesion | Excellent, versatile adhesion | Adhesion can vary |

| Fire Retardancy | Some formulations are fire-retardant | Typically not fire-retardant |

While silicone suits general sealing, acoustic sealant excels at soundproofing, offering long-lasting seals and potential fire protection. Proper application is crucial for optimal performance – always follow manufacturer instructions.

Why Use Acoustic Sealant on Vapor Barriers?

Vapor barriers are crucial for moisture protection, but even the best installations can have tiny gaps. Acoustic sealant seals these gaps, creating a robust, airtight barrier. Think of it as boosting your vapor barrier’s superpowers.

Benefits

- Quieter Spaces: Dampens sound vibrations traveling through gaps.

- Energy Savings: Seals air leaks, improving insulation and lowering energy bills.

- Moisture Protection: Further reduces moisture infiltration, preventing mold and mildew.

- Easy Application: Simple DIY application with a caulk gun.

Applying Acoustic Sealant on Vapor Barriers: A Step-by-Step Guide

- Prepare the Surface: Ensure the vapor barrier is clean and dry.

- Apply the Sealant: Apply a continuous bead along gaps and cracks.

- Smooth the Sealant: Use a putty knife or gloved finger for a smooth, effective seal.

- Drying Time: Allow to dry completely according to the manufacturer’s instructions.

Considerations

While generally effective, temperature extremes can influence acoustic sealant’s performance. Ongoing research is exploring how different formulations perform in various climates. Always choose a high-quality sealant designed for acoustic applications.

Looking Ahead

Scientists are continually developing sealant technologies. Research into nanomaterials, for instance, promises further advancements in soundproofing and insulation. Using acoustic sealant on vapor barriers is a simple, cost-effective way to achieve a quieter, more comfortable, and energy-efficient home.

Key Points of Acoustic Sealant:

- Definition: A sound-absorbing material that blocks sound transmission by converting vibrations into heat energy.

- Benefits: Reduces noise, enhances sound quality, may offer fire resistance, protects against drafts and moisture, improves energy efficiency.

- Applications: General soundproofing, sealing air leaks, construction and renovation projects.

- Choosing Acoustic Sealant: Consider base material, application method, and specific properties.

- Applying Acoustic Sealant: Clean surfaces, apply a continuous bead, smooth, and remove excess.

- Greenhouse Storage Shed Combos: Your Guide to Combining Growing and Storage - April 21, 2025

- Greenhouse Shed Combo: Design, Build & Grow Year-Round - April 21, 2025

- Gingham vs. Plaid: What’s the Difference? A Complete Guide - April 21, 2025