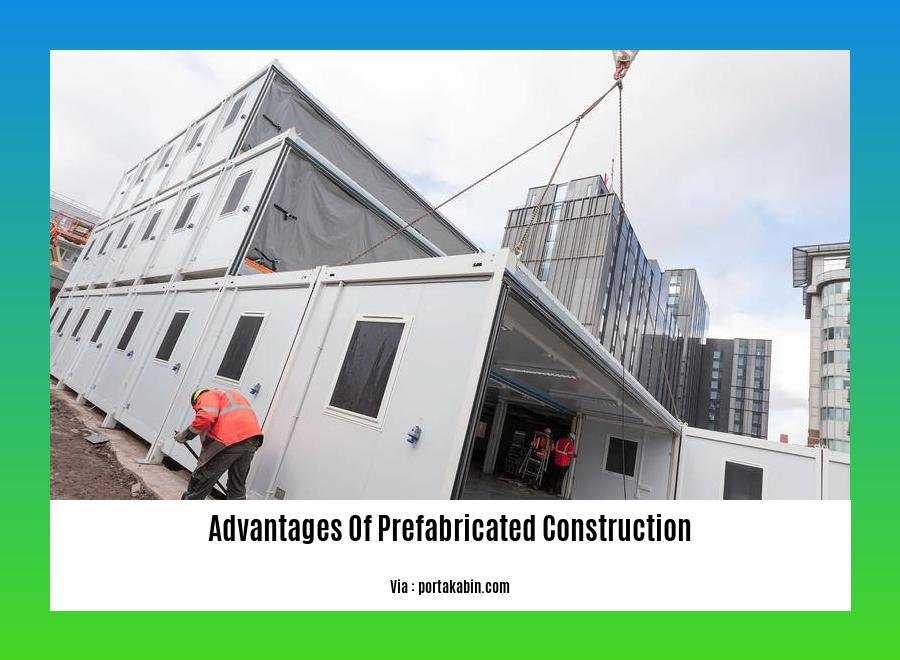

In today’s rapidly evolving construction industry, prefabricated construction has emerged as a beacon of innovation and efficiency. This article delves into the advantages of prefabricated construction, exploring how it can pave the way for a more efficient, sustainable, and cost-effective approach to building. [- The Advantages of Prefabricated Construction: A Path to Innovation and Efficiency]

Key Takeaways:

- Enhanced Durability: Prefabs offer exceptional durability due to robust materials like pre-cast concrete and light-gauge steel frames.

- Accelerated Construction: Prefabrication significantly reduces construction time by assembling pre-manufactured components on-site.

- Reduced Environmental Impact: Prefabs minimize waste, pollution, and environmental disturbances, promoting sustainability.

- Enhanced Quality Control: Prefab components are manufactured in controlled settings, ensuring high quality and precision.

- Safety Enhancement: Prefabrication reduces on-site construction risks as components are pre-assembled and inspected before installation.

- Process Simplification: Prefabs streamline construction processes and timelines, facilitating efficient project management.

- Cost-Effectiveness: Prefabricated construction offers lower costs compared to traditional methods due to reduced labor, materials, and time.

- Eco-Friendliness: Prefabs minimize environmental impact by reducing waste, pollution, and energy consumption during installation and assembly.

- Materials Customization: Prefabricated components allow for flexibility in design and materials selection, catering to specific architectural requirements.

- Off-Site Manufacturing: Off-site manufacturing protects materials from weather conditions and enables continuous production, minimizing delays.

: Maseu/HST: Sax, tsexe te

Explore the advantages of construction equipment, and learn how it can streamline your construction projects. Discover the advantages of construction management to enhance project efficiency and reduce costs. Gain insights into the advantages of prefabrication for faster and more sustainable construction. Unearth the advantages of steel frame for robust and durable structures. And, delve into the advantages of steel structures to unlock cost-effectiveness and aesthetic appeal.

Time efficiency: Prefabrication’s superpower

Prefabricated construction is a time-saving superhero in the construction industry. By producing components off-site and assembling them on-site, prefabrication shaves weeks, even months, off project timelines. Concurrent production and site prep work their magic, making this construction method up to 50% faster than traditional approaches. [1]

How does prefabrication achieve this time-bending feat? Let’s break it down:

-

Factory precision: Prefab components are manufactured in controlled environments, ensuring accuracy and reducing errors. This precision eliminates the need for rework and delays on-site.

-

Concurrent processes: With prefabrication, different project phases can happen simultaneously. While crews assemble foundations on-site, prefabricated modules are being crafted off-site. This overlap significantly reduces overall project duration.

-

Reduced weather impact: Prefabrication takes place indoors, shielding components from weather delays. This means projects can progress steadily, regardless of rain, snow, or shine.

Key Takeaways:

- Concurrent production and site preparation reduce project timelines by up to 50%.

- Prefabrication’s factory precision minimizes errors and rework, saving time on-site.

- Protection from weather delays keeps projects on track.

Citations:

[1] UtilitiesOne:

Reduced environmental impact

Prefabrication offers a multitude of benefits for the environment, contributing to a more sustainable construction industry. By adopting prefabricated techniques, we significantly reduce emissions, conserve natural areas, and minimize disturbance to local wildlife.

Conserving Resources

The controlled factory environment of prefabrication leads to efficient resource utilization. Water conservation is achieved through automated processes, while recycling of materials is facilitated, reducing waste and promoting sustainability.

Mitigating Emissions

Prefabrication reduces emissions by optimizing transportation logistics and minimizing on-site construction activities. The centralized production of prefabricated components eliminates the need for multiple deliveries of materials to the construction site.

Key Takeaways:

- Reduces emissions and conserves natural areas

- Facilitates recycling and efficient resource utilization

- Promotes sustainable construction practices

Relevant URL Sources:

- L1: Prefabrication: All Advantages & Disadvantages Explained. (2021, January 18). VinCivilWorld.

- L2: Teng, Y., Li, K., Pan, W., & Ng, T. (2018). Environmental and Economic Performance of Prefabricated Construction. ScienceDirect, 2(22), 386-395.

Enhanced Sustainability: A Key Advantage of Prefabricated Construction

Prefabrication has gained recognition as an innovative construction method, not just for its efficiency and cost-effectiveness but also for its significant contributions to sustainability. Let’s dive into how prefabrication enhances sustainability in the construction industry:

-

Reduced Waste Generation: Prefabricated structures are meticulously planned and manufactured in controlled factory settings, minimizing material waste and reducing emissions associated with on-site construction.

-

Energy Efficiency: Prefabricated buildings often incorporate energy-efficient features such as high-performance insulation and efficient lighting systems. This reduces energy consumption and lowers operating costs.

-

Environmental Compliance: Prefabricated structures can meet green building standards, ensuring a healthier indoor environment for occupants and contributing to the overall eco-friendliness of the project.

Key Takeaways:

- Prefabricated construction reduces waste generation during construction, minimizing environmental impact.

- Energy-efficient design features in prefabricated structures decrease overall energy consumption, resulting in lower utility costs.

- Meeting green building standards ensures a healthier indoor environment for occupants and contributes to eco-friendliness.

Relevant Sources:

- Sustainable Prefabricated Modular Buildings: A Review

- Environmental and economic performance of prefabricated construction

FAQ

Q1: What are the key reasons behind the increasing adoption of prefabricated construction?

A1: Prefabricated construction offers numerous advantages, including enhanced durability, accelerated construction timelines, reduced environmental impact, enhanced quality control, safety enhancement, process simplification, cost-effectiveness, eco-friendliness, material versatility, and off-site manufacturing capabilities.

Q2: How does prefabrication contribute to reduced construction waste?

A2: Prefabrication minimizes construction waste by employing precise manufacturing processes in controlled factory settings. It eliminates the need for extensive on-site cutting and assembly, resulting in less material wastage.

Q3: In what ways does prefabrication promote sustainability in the construction industry?

A3: Prefabrication contributes to sustainability by reducing waste generation, minimizing environmental disturbances, conserving natural resources, and facilitating the adoption of energy-efficient designs. It promotes responsible construction practices and contributes to a greener built environment.

Q4: How does prefabrication positively impact the project duration and cost?

A4: Prefabrication streamlines construction processes by allowing for concurrent production of components and efficient on-site assembly. This approach reduces overall construction timelines by up to 50% and leads to significant cost savings due to reduced labor requirements, material waste, and project delays.

Q5: What are the potential challenges associated with prefabricated construction?

A5: While prefabrication offers numerous benefits, it also presents certain challenges. These may include potential design limitations due to standardized component dimensions, the need for specialized transportation and handling equipment, and the potential for delays caused by disruptions in the manufacturing process or supply chain logistics. However, these challenges can be effectively addressed through careful planning, collaboration, and quality control measures.

- 30+ Beautiful Flowers That Start With N (Pictures and Growing Guides) - April 22, 2025

- 40+ Flowers That Start With L: A Comprehensive Guide - April 22, 2025

- 20+ Fabulous Flowers That Start With J: A Complete Guide - April 22, 2025