Unveiling the Step-by-Step Guide to Asphalt Road Construction Procedure: Unraveling the Best Practices: Step into the realm of asphalt road construction and embark on a comprehensive journey through its intricate procedures. From meticulous planning and design to expert execution and vigilant maintenance, this guide will unveil the secrets behind building enduring asphalt roads that withstand the test of time and the rigors of heavy traffic. Discover the nuances of material selection, mix design, and compaction techniques, and delve into the depths of project management, budgeting, and quality control. Prepare to navigate the challenges of asphalt road construction with finesse, ensuring safety, efficiency, and adherence to environmental standards. Embark on this educational odyssey and emerge a maestro of asphalt road construction.

Key Takeaways:

- Demolition and Removal:

-

Remove existing surfaces using machinery and dispose of debris.

-

Grading and Sloping:

-

Level the area and create slopes for water drainage using laser-guided transits and automatic motor graders.

-

Prepare the Sub Base:

-

Lay a stable foundation for the asphalt surface and ensure stability by compacting and leveling.

-

Proof Roll, Undercutting, and Sub Base Repair:

-

Compact the sub base to identify and remove soft spots, then replace them with new material.

-

Binder and Surface Course:

-

Apply a binder course for a strong bond between the sub base and surface course, then lay the top asphalt layer.

-

Install New Asphalt Surface:

-

Spread the asphalt mixture evenly and compact it to achieve desired density and smoothness.

-

Butt Joints and Transitions:

- Create smooth transitions between new and existing asphalt surfaces and saw-cut joints to prevent cracking and ensure a uniform appearance.

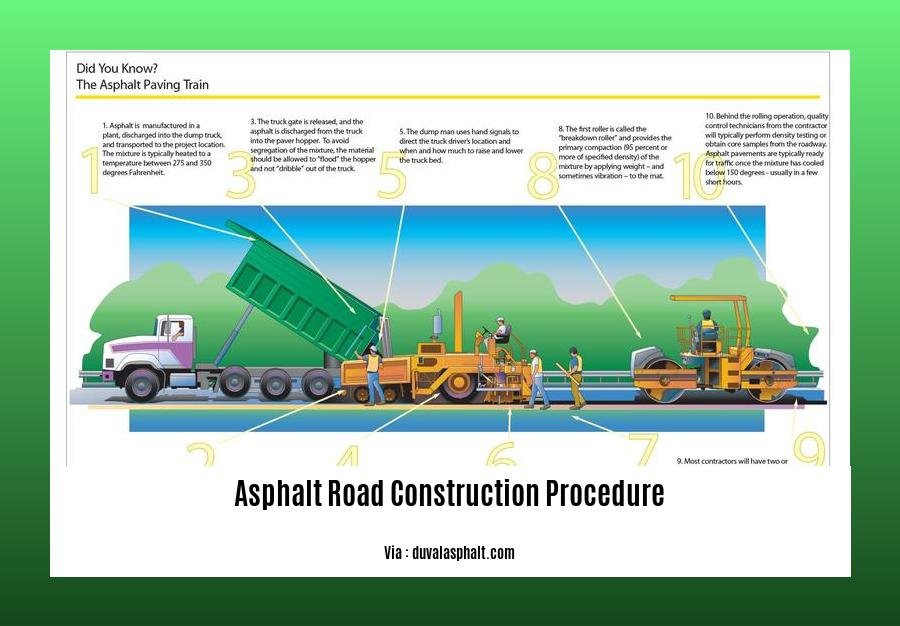

Asphalt Road Construction Procedure

Building or repairing asphalt roads involves a standardized set of steps to achieve a durable and smooth surface. Let’s explore the asphalt road construction procedure, from preparation to final touches:

1. Planning and Design:

– Analyze Site: Assess the area to determine the thickness and type of asphalt required.

– Determine Materials: Select appropriate asphalt mix and materials for base layers.

– Plan Drainage: Design proper drainage systems to prevent water accumulation.

2. Site Preparation and Excavation:

– Demolish Existing Surface: Remove old asphalt or concrete layers using specialized equipment.

– Excavate Subgrade: Dig out the underlying soil to the desired depth.

– Grade and Compact: Shape the subgrade to ensure proper slope and compact it for stability.

3. Laying the Base Layer:

– Install Geotextile Fabric: Place a fabric barrier to separate the subgrade from the base layer.

– Spread Aggregate Base: Apply a layer of crushed rock or gravel, compacting it to create a solid foundation.

4. Asphalt Binder Course:

– Apply Tack Coat: Spray a thin layer of asphalt to ensure proper bonding between layers.

– Lay Binder Course: Install the first asphalt layer, typically composed of larger aggregates.

– Compact and Smooth: Use rollers to compact the binder course and create a uniform surface.

5. Asphalt Surface Course:

– Prepare Tack Coat: Apply a thin layer of asphalt emulsion to enhance bonding.

– Install Surface Course: Lay the final asphalt layer, usually made of finer aggregates.

– Compact and Roll: Compact and smooth the surface course to achieve the desired texture and density.

6. Compaction and Finishing Touches:

– Compact Entire Surface: Use rollers to compact the entire asphalt pavement, ensuring evenness.

– Apply Sealcoat: Spray a protective sealcoat to prolong the life of the asphalt surface.

– Markings and Signs: Paint traffic markings, install signage, and add safety features as needed.

7. Quality Control and Maintenance:

– Regular Inspections: Conduct routine checks to identify any issues early on.

– Repair and Resurface: Address any cracks or повреждения promptly to prevent further deterioration.

– Maintenance Schedule: Develop a long-term maintenance plan to keep the asphalt road in good condition.

By following these steps and best practices, road construction professionals can build or repair asphalt roads that are durable, safe, and withstand heavy traffic loads and environmental conditions.

-

Want to connect with an agency that supplies construction workers in Singapore? Look no further, explore this agency for construction workers in Singapore for more details.

-

If you are considering construction work in London, connect with a reliable agency. Explore this agency work London construction to find the right fit for your career needs.

-

Seeking top-notch asphalt road construction machines? Discover the latest equipment and technologies by visiting our asphalt road construction machines page.

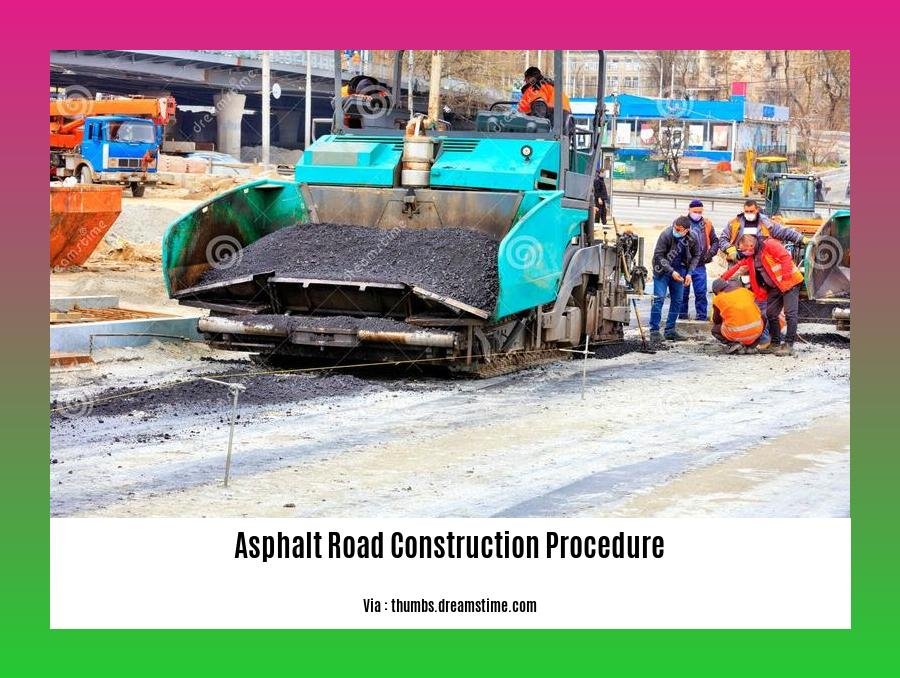

Installing the asphalt surface course: This involves laying down a final layer of hot asphalt mix, which is then compacted to create a smooth and skid-resistant surface.

This step is critical in creating a durable and safe asphalt road surface. Here’s a closer look at the process:

1. Preparation:

- The first step is to prepare the binder course by applying a thin layer of tack coat, which acts as an adhesive between the binder and surface courses.

2. Laying the Surface Course:

- Once the tack coat has dried, the surface course is applied. This course is typically composed of a mix of smaller aggregate and oil.

- It is important to ensure that the surface course is applied evenly and at the correct thickness.

3. Compaction:

- After the surface course is laid, it must be compacted using heavy rollers.

- Compaction helps to eliminate air pockets and create a dense, stable surface.

- Multiple passes with the roller may be necessary to achieve the desired compaction level.

4. Finishing Touches:

- Once the surface course has been compacted, it is typically sealed with a thin layer of asphalt emulsion.

- This sealcoat helps to protect the surface from wear and tear and improves its longevity.

- Additional treatments, such as pavement markings and signage, can also be applied at this stage.

Key Takeaways:

- Preparation: Applying a tack coat to the binder course is crucial for ensuring adhesion between the two layers.

- Laying: The surface course should be applied evenly and at the correct thickness to ensure a smooth and durable surface.

- Compaction: Proper compaction using heavy rollers is essential for eliminating air pockets and creating a dense, stable surface.

- Finishing: Sealing the surface course with asphalt emulsion helps protect it from wear and tear and improves its longevity.

Citations:

Limitless Golden Construct: Asphalt Paving Process – What You Need To Know

Business Partner Magazine: Installing Asphalt Pavement – A Step-by-Step Guide

Quality control: This involves testing the asphalt to ensure that it meets the required specifications.

Asphalt road construction is a complex process that requires careful planning, execution, and quality control. To ensure the finished product is durable, safe, and meets industry standards, regular testing of the asphalt is crucial. Let’s dive into the significance of quality control in asphalt road construction:

Key Takeaways:

- Asphalt testing helps ensure that the materials and construction methods meet project specifications and industry standards.

- Regular testing identifies quality issues early on, preventing costly repairs and ensuring the road’s longevity.

- Quality control measures guarantee a safe and durable road surface that can withstand heavy traffic and extreme weather conditions.

- Proper testing protocols help maintain the integrity of the road, extending its lifespan and reducing maintenance costs.

Benefits of Quality Control in Asphalt Road Construction:

- Increased Durability: Regular testing ensures the asphalt is properly compacted and free of defects, resulting in a longer-lasting road surface.

- Enhanced Safety: Quality control measures help prevent premature road failures and defects, reducing the risk of accidents and ensuring a smooth and safe driving experience.

- Cost Savings: Identifying and addressing quality issues early on helps prevent costly repairs and premature road deterioration, leading to significant savings in maintenance and reconstruction costs.

- Improved Sustainability: By ensuring the asphalt is properly designed and constructed, quality control contributes to reduced energy consumption and lower carbon emissions, promoting sustainable road construction practices.

Types of Asphalt Tests:

Asphalt testing encompasses a wide range of tests to evaluate various properties of the material. Some of the most commonly performed tests include:

- Asphalt Mix Design: This test determines the optimal proportions of aggregate, asphalt binder, and additives to achieve the desired properties of the asphalt mixture.

- Compaction Testing: Compaction tests ensure that the asphalt is properly compacted to achieve the required density and strength.

- Segregation Testing: Segregation testing checks for the uniform distribution of asphalt binder and aggregate throughout the mixture.

- Thickness Testing: Thickness testing verifies that the asphalt layer is laid to the specified depth.

- Durability Testing: Durability tests evaluate the resistance of the asphalt to cracking, rutting, and wear.

Quality Control Process:

The quality control process for asphalt road construction typically involves the following steps:

- Establishing Quality Control Plan: The project’s quality control plan outlines the specific tests to be performed, the frequency of testing, and the acceptance criteria for each test.

- Sampling and Testing: During construction, samples of the asphalt mixture are taken at regular intervals and tested according to the established quality control plan.

- Data Analysis: The test results are analyzed to determine if the asphalt meets the required specifications.

- Corrective Actions: If any test results fall outside the acceptance criteria, corrective actions are taken to address the quality issues. This may involve adjusting the asphalt mix design, construction methods, or equipment.

Conclusion:

Quality control plays a vital role in ensuring the durability, safety, and longevity of asphalt roads. By conducting regular testing and implementing corrective actions when necessary, road construction professionals can deliver high-quality asphalt roads that meet industry standards and provide a smooth and safe driving experience for years to come.

Sources:

- Asphalt Testing: Importance and Benefits

- Quality Control and Quality Assurance in Asphalt Pavement Construction

Maintaining the asphalt road: This includes sealing cracks and repairing potholes to extend the life of the road.

Taking care of your asphalt road goes a long way in ensuring its longevity and smooth experience for drivers. By implementing a proactive maintenance plan that includes sealing cracks and repairing potholes, you can extend the life of your asphalt road, saving both time and money in the long run.

Key Takeaways:

- Seal Cracks Promptly:

-

Cracks, if left unattended, can allow water to seep into the asphalt, causing further damage and premature deterioration. This can be prevented by sealing cracks as soon as they appear.

-

Repair Potholes Quickly:

-

Potholes are another common issue that can cause damage to your asphalt road. These can be filled using a pothole patching kit or by hiring a professional paving contractor.

-

Regular Inspections:

-

Regularly inspect your asphalt road for signs of damage, such as cracks, potholes, or crumbling edges. Promptly address any issues you find to prevent further deterioration.

-

Preventative Maintenance:

-

Preventative maintenance measures, such as sealcoating and crack filling, can help extend the lifespan of your asphalt road by protecting it from the elements and wear and tear.

-

Professional Assistance:

- For larger repairs or if you lack the necessary expertise, consider hiring a professional paving contractor. They can provide the necessary equipment and expertise to effectively repair and maintain your asphalt road.

Essential Steps to Maintaining an Asphalt Road:

1. Seal Cracks Promptly:

- Identify cracks early on by conducting regular inspections.

- Clean the crack thoroughly to remove dirt and debris.

- Apply a crack sealant using a squeegee or specialized equipment.

- Allow the sealant to dry completely before allowing traffic.

2. Repair Potholes Quickly:

- Clean the pothole to remove loose debris and vegetation.

- Fill the pothole with a patching material, such as hot asphalt or cold patch mix.

- Compact the patching material to ensure a smooth and level surface.

- Allow the patch to cure completely before allowing traffic.

3. Regular Maintenance:

- Regularly inspect the asphalt road for signs of damage.

- Address any minor issues promptly to prevent further deterioration.

- Consider sealcoating the road every 2 to 3 years to protect it from the elements.

By following these steps, you can effectively maintain your asphalt road, extending its lifespan and ensuring a smooth and safe driving experience for all.

[Citation]

- Asphalt Maintenance: Guidelines for Long-term Protection

- Asphalt Maintenance and Rehabilitation

FAQ

Q1: What are the key steps involved in asphalt road construction?

A1: Asphalt road construction typically involves several key steps, including demolition and removal of existing surfaces, grading and sloping for proper drainage, preparing the sub base for stability, proof rolling and repairing soft areas, and finally installing the binder and surface course layers.

Q2: How do you prepare the sub base for asphalt pavement?

A2: Preparing the sub base involves laying down a stable foundation material, compacting it to prevent movement and settling, and repairing any soft areas to ensure a strong foundation for the asphalt pavement.

Q3: What is the purpose of the proof roll step in asphalt road construction?

A3: The proof roll step is crucial to identify weak areas in the sub base. By compacting the sub base with a roller truck, soft or unstable areas can be identified and subsequently undercut and repaired to ensure a solid foundation for the asphalt pavement.

Q4: What are the considerations for asphalt pavement maintenance?

A4: Asphalt pavement maintenance involves several important aspects, including sealing the asphalt surface to protect it from the elements, choosing the right sealant, resealing regularly to maintain protection, repairing cracks promptly to prevent further damage, and filling potholes quickly to prevent expansion.

Q5: How can I ensure the longevity and performance of asphalt pavement?

A5: Ensuring the longevity and performance of asphalt pavement requires proper installation techniques, high-quality materials, and regular maintenance practices. Regular testing and quality control measures help ensure the asphalt pavement meets specifications and standards, contributing to its long-lasting performance.

- Black Backsplash Tile: Find The Perfect Style For Your Kitchen - November 6, 2025

- Black Backsplash With White Cabinets: A Bold Kitchen Design - November 5, 2025

- Black and White Kitchen Backsplash: Ideas for Timeless Style - November 4, 2025