Unveiling the Intricacies of Asphalt Road Construction Process: A Comprehensive Guide for Professionals

As a skilled civil engineer with over a decade of expertise in asphalt road construction, I am excited to guide you through the intricacies of this vital process. Together, we will delve into the steps involved, starting with demolishing and removing existing asphalt, expertly determining grading and sloping, and meticulously preparing and compacting the sub-base. Additionally, I’ll equip you with the skills to pinpoint potential weak or soft spots, arming you with the knowledge to ensure the longevity and safety of your asphalt roadways. Let’s pave the way to excellence in asphalt road construction!

Key Takeaways:

-

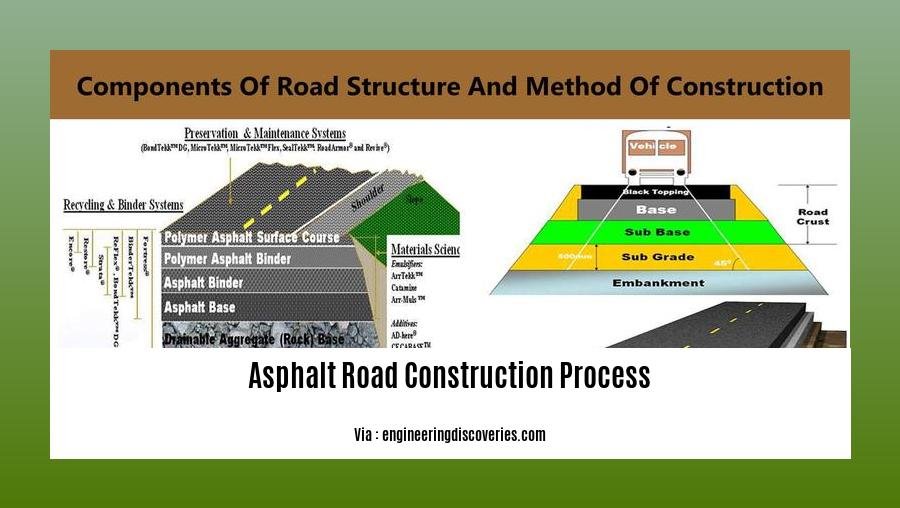

Asphalt road construction involves multiple layers, each serving a specific purpose.

-

Site preparation includes clearing vegetation, removing debris, and leveling the surface.

-

Subbase preparation provides stability and support, typically made of compacted soil or crushed materials.

-

Base course provides structural strength and support, composed of compacted crushed stone or asphalt-treated materials.

-

Binder course binds the base course and surface course together, distributing traffic loads and enhancing stability.

-

Surface course is the final layer that comes in direct contact with traffic, providing durability, skid resistance, and smoothness.

-

Compaction is crucial for achieving the desired density and stability of each layer.

-

Joints and transitions accommodate movement and prevent cracking at different pavement sections, bridges, and intersections.

-

Finishing and curing involve achieving the desired smoothness and texture, as well as allowing the asphalt to gain strength before opening to traffic.

-

Sources:

- Road Construction Process

- The Complete 7-Step Process for Asphalt Pavement Installation

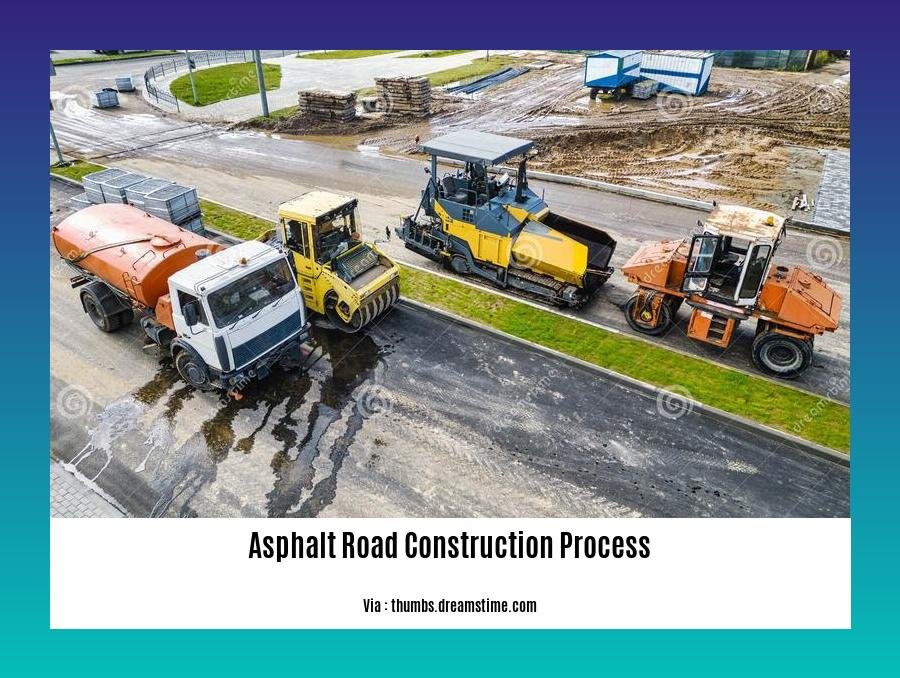

Asphalt Road Construction Process

The asphalt road construction process is a complex and precise endeavor that demands expertise, attention to detail, and adherence to stringent quality standards. This comprehensive guide delves into the intricacies of the asphalt road construction process, providing valuable insights and practical knowledge for professionals involved in this field.

1. Site Preparation:

– Before embarking on road construction, thorough site preparation is essential. This involves clearing vegetation, removing debris, and leveling the surface to create a stable foundation.

2. Subbase Preparation:

– The subbase layer provides stability and support to the road. It is typically composed of compacted soil or a combination of materials like crushed stone, gravel, or recycled asphalt.

3. Base Course:

– The base course is a crucial layer that provides structural strength and support to the road. It is typically made of compacted crushed stone or asphalt-treated materials, ensuring the road’s longevity.

4. Binder Course:

– The binder course acts as a binding agent, connecting the base course and surface course. This hot mix of asphalt cement and aggregate distributes traffic loads and enhances stability.

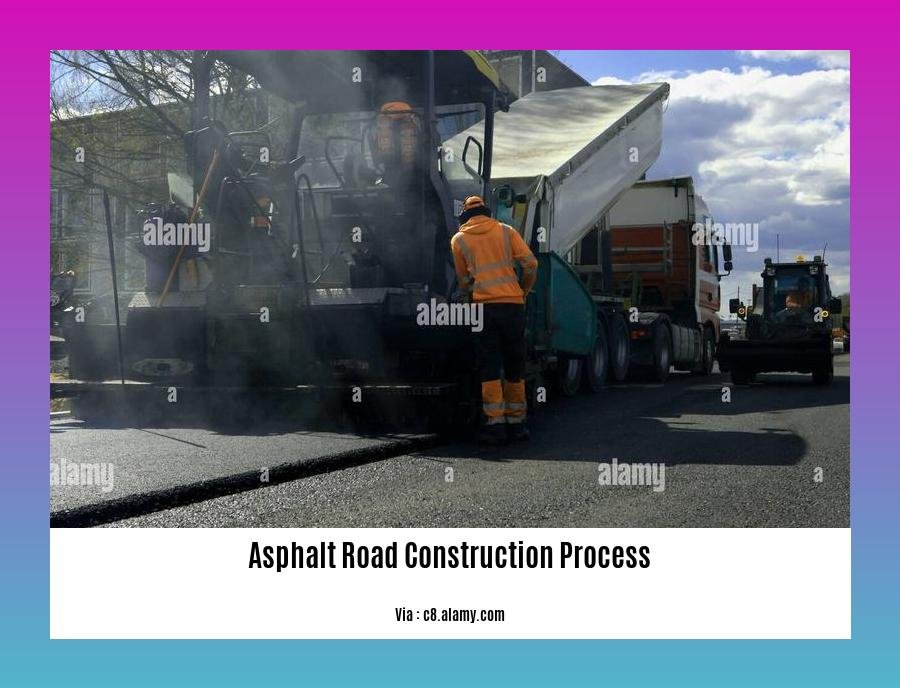

5. Surface Course:

– The surface course is the final layer that directly interfaces with traffic. It is composed of a hot mix of asphalt cement, aggregate, and additives designed to provide durability, skid resistance, and smoothness.

6. Compaction:

– Each layer of the road, including the base course, binder course, and surface course, undergoes compaction using heavy rollers. This process achieves the desired density and stability, ensuring the road’s integrity and longevity.

7. Joints and Transitions:

– Joints and transitions are constructed where different pavement sections meet. They accommodate movement, prevent cracking, and ensure a smooth transition between asphalt and concrete pavements, expansion joints, and bridges or intersections.

8. Finishing and Curing:

– After laying the surface course, it is finished to achieve the desired smoothness and texture. Curing is vital for the asphalt to gain strength, typically achieved by restricting traffic or applying curing compounds.

By understanding and meticulously executing each step of the asphalt road construction process, professionals can ensure the construction of durable, safe, and efficient roadways that will serve communities for years to come.

If you want to explore the construction industry in Australia, then check out Australia’s top construction companies to stay updated with their latest projects and innovations. For more impressive construction work, Avenue Construction Company has been consistently delivering creative and sustainable solutions in the industry, so make sure to visit their portfolio.

3. Prepare and Compact the Sub-Base

When it comes to asphalt road construction, the sub-base is a critical layer responsible for providing stability, preventing frost damage, and ensuring proper drainage. Its preparation and compaction demand precision to create a solid foundation for the asphalt layers.

Key Takeaways:

-

Stability Provision: The sub-base layer plays a vital role in distributing traffic loads and preventing the asphalt layers from cracking and deteriorating.

-

Frost Damage Prevention: In regions prone to freezing temperatures, a well-prepared sub-base acts as a barrier, minimizing frost penetration and protecting the road structure from damage caused by freeze-thaw cycles.

-

Drainage Facilitation: The sub-base assists in draining water away from the asphalt surface, preventing water accumulation and ensuring the road’s longevity.

-

Compaction Necessity: Proper compaction of the sub-base is essential to achieve the desired density, stability, and load-bearing capacity, ensuring the road can withstand traffic loads without deformation or settlement.

Steps for Sub-Base Preparation and Compaction:

-

Excavation and Grading: Excavate the area to the desired depth and grade it to create a uniform surface.

-

Sub-Base Material Selection: Choose the appropriate sub-base material based on factors such as soil conditions, traffic volume, and climatic conditions. Common materials include crushed stone, gravel, recycled asphalt, and soil cement.

-

Laying and Spreading: Spread the sub-base material evenly over the prepared area using dump trucks or specialized equipment.

-

Compaction: Compact the sub-base material using heavy rollers, such as vibratory rollers or static rollers, to achieve the specified density and stability. The compaction process may require multiple passes to achieve the desired results.

-

Adjustment and Recompaction: Inspect the compacted sub-base for any soft spots or uneven areas. Adjust and recompact these areas to ensure a uniform and stable sub-base.

-

Proof Rolling: Conduct proof rolling with a heavy roller to identify any weak areas or potential problems in the sub-base. Address these issues before proceeding to the next construction phase.

Citation:

- Asphalt Pavement Construction: A Guide to the Process

- How to Build an Asphalt Road: Step-by-Step Guide

4. Pinpoint Potential Weak or Soft Spots

To ensure the structural integrity and durability of an asphalt road, thoroughly inspecting and rectifying weak or soft spots in the sub-base is vital. This step plays a critical role in preventing premature deterioration, cracking, and other issues that could compromise the road’s performance.

Key Takeaways:

- Weak or soft spots in the sub-base can lead to structural issues, premature deterioration, and cracking.

- Proof rolling is a common method used to identify these compromised areas.

- Areas with excessive deflection or movement during the proof rolling process should be addressed promptly.

- Repairs can involve removing and replacing the affected section, adding stabilizing materials, or applying geotextiles for reinforcement.

- Proper compaction and quality control measures help minimize the occurrence of weak spots, ensuring the long-term integrity of the asphalt road.

Proof Rolling Technique:

- Proof rolling involves using a heavy roller to simulate traffic loads and expose any weak spots in the sub-base.

- The roller is systematically moved across the sub-base, observing areas that exhibit excessive deflection or movement.

- These areas are marked for further investigation and subsequent repairs.

Remediation Measures:

- If the weak spots are isolated and relatively minor, they can be addressed by removing and replacing the affected section with properly compacted material.

- In cases where the affected area is more extensive, stabilization techniques such as adding cement or lime may be necessary to improve the sub-base’s strength and stability.

- Geotextiles, which are synthetic fabrics, can also be used to reinforce the sub-base and prevent further movement or settlement.

By diligently identifying and rectifying potential weak or soft spots in the sub-base, you can significantly enhance the overall performance and longevity of the asphalt road.

Citations:

FAQ

Q1: Why is it essential to properly demolish and remove existing asphalt during road construction?

A1: Proper demolition and removal of existing asphalt are crucial to ensure a solid foundation for the new asphalt pavement. This process eliminates any weak or damaged areas, ensuring the new asphalt will have a stable base to adhere to and increasing the longevity of the new road.

Q2: What is the significance of grading and sloping in the asphalt road construction process?

A2: Grading and sloping are essential for managing water runoff and preventing damage to the asphalt pavement. Proper grading and sloping allow water to drain efficiently, reducing the risk of erosion and ensuring the asphalt surface remains intact and safe for vehicles.

Q3: How does preparing and compacting the sub-base contribute to the integrity of the asphalt road?

A3: Preparing and compacting the sub-base is crucial for providing a stable and supportive foundation for the asphalt pavement. This process involves compacting the soil or other materials used as the sub-base to ensure it can withstand the weight of the asphalt and traffic loads. Proper compaction prevents the sub-base from settling or shifting, which can lead to cracks and damage to the asphalt surface.

Q4: Why is it important to pinpoint potential weak or soft spots in the sub-base before installing the asphalt pavement?

A4: Identifying and repairing weak or soft spots in the sub-base is essential to prevent premature deterioration and structural issues in the asphalt pavement. Testing the sub-base for these areas allows contractors to address and correct any weaknesses before installing the asphalt, reducing the likelihood of future problems and increasing the overall lifespan of the road.

Q5: How does proper compaction of each asphalt layer contribute to the durability and performance of the asphalt road?

A5: Proper compaction of each asphalt layer is crucial for achieving the desired density and strength of the asphalt pavement. Compaction ensures the asphalt is tightly packed, reducing the risk of air pockets or voids that can weaken the pavement. Proper compaction also enhances the asphalt’s resistance to wear and tear, extending its lifespan and minimizing the need for frequent repairs or maintenance.

- Dora the Explorer Wipe-Off Fun: Safe & Mess-Free Activities for Little Explorers - April 18, 2025

- Does Lemongrass Repel Mosquitoes? Fact vs. Fiction + How to Use It - April 18, 2025

- Do Woodchucks Climb Trees?Fact vs. Fiction - April 18, 2025