Discover the multifaceted world of GRC (Glass Reinforced Concrete) in construction. This innovative material revolutionizes the industry, offering unparalleled benefits for architects, engineers, and contractors alike. Delve into the GRC meaning in construction and uncover its transformative potential for your next project.

Key Takeaways:

- GRC (Glassfibre Reinforced Concrete) is widely used in construction.

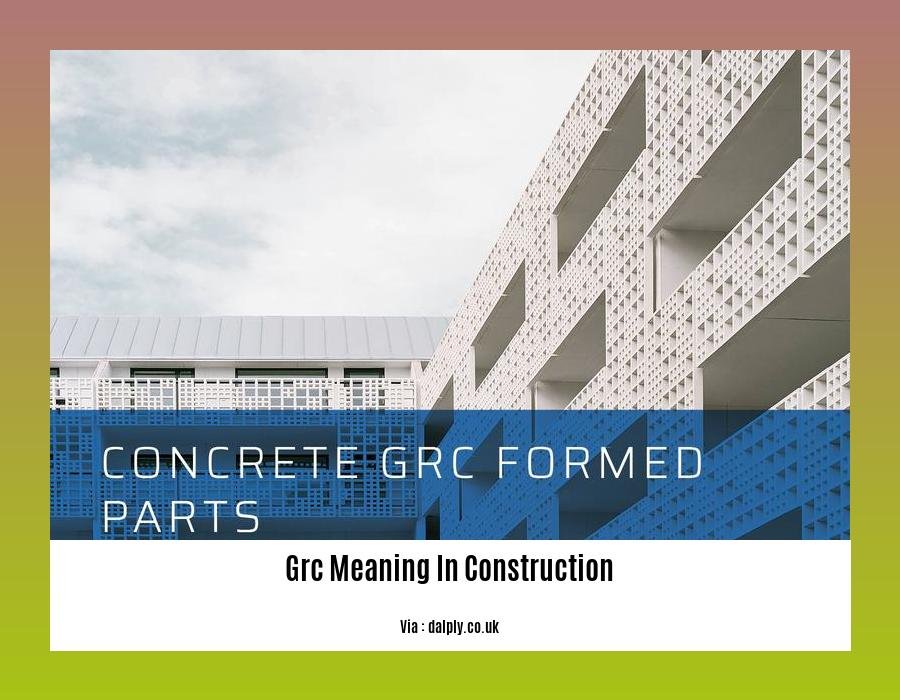

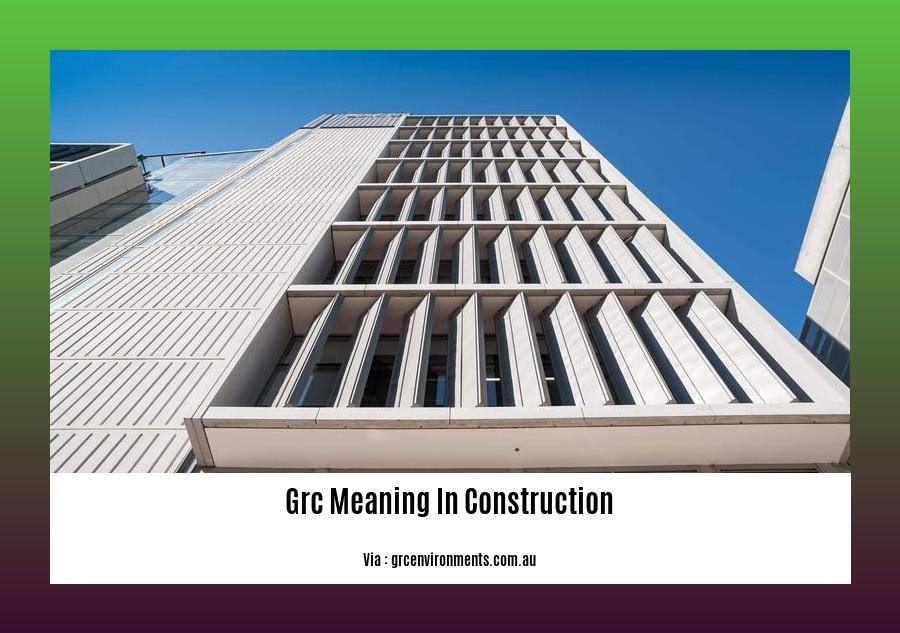

- GRC serves as exterior building facade panels and architectural precast concrete.

GRC Meaning in Construction

Glass Reinforced Concrete (GRC) is a versatile and unique building material that combines the strength of concrete with the flexibility of glass fibers. It’s a high-performance composite that offers exceptional durability, aesthetics, and design versatility.

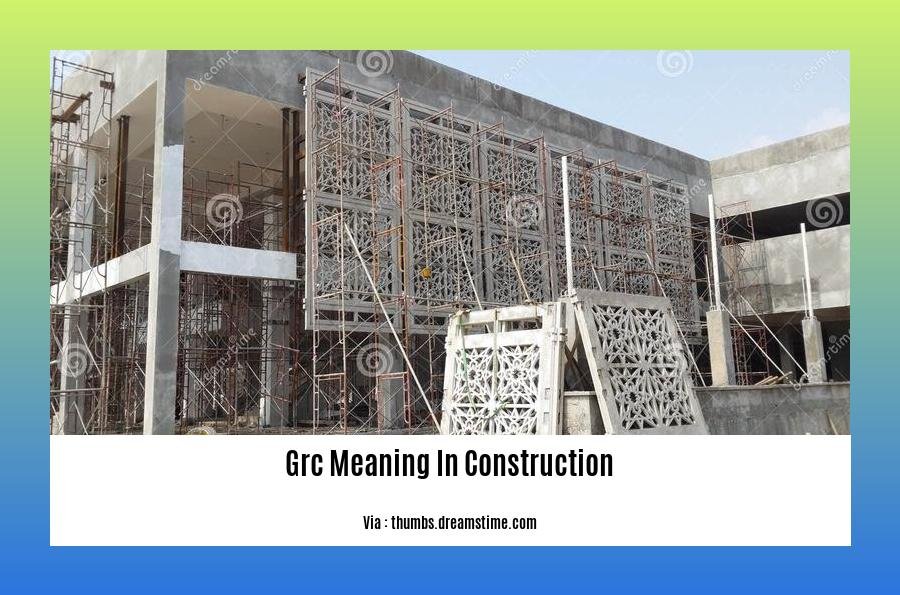

GRC is a type of concrete reinforced with glass fibers, making it incredibly strong and resistant to cracking. It’s commonly used in exterior building façade panels and architectural precast concrete elements. GRC can be molded into complex shapes, allowing for intricate architectural designs.

One of the key advantages of GRC lies in its strength and durability. The glass fibers enhance the concrete’s tensile strength, making it resistant to bending and impact forces. It also exhibits excellent fire resistance and weatherability, ensuring longevity and low maintenance costs.

Aesthetically, GRC provides architects with a wide range of design options. It can be finished in various colors and textures, mimicking the look of natural materials like stone or wood. GRC’s versatility allows for seamless integration with different architectural styles, from traditional to contemporary.

In terms of sustainability, GRC offers several benefits. It’s a lightweight material, reducing the overall weight of structures and transportation costs. Additionally, GRC can incorporate recycled materials, contributing to environmental conservation.

Overall, the GRC meaning in construction signifies a high-performance building material that combines strength, durability, aesthetics, and design flexibility. It’s an ideal choice for architects and engineers seeking innovative and sustainable solutions for their projects.

Unveiling the Science Behind buffing in construction, a Technique for Enhancing Structural Integrity.

Discover the Significance of Gradation in Construction, a Factor Influencing Concrete Quality and Durability.

Unlocking the Mystery of GRC Full Form in Construction: Glassfiber Reinforced Concrete and Its Applications in Modern Building.

Different types of GRC and their uses

Glass Reinforced Concrete (GRC) is a type of fiber-reinforced concrete that uses glass fibers to enhance its strength and durability. GRC is a versatile material that can be used in a variety of applications, including:

- Exterior building façade panels

- Architectural precast concrete

- Cladding

- Renovation

- Foundations

Key Takeaways:

- GRC is a lightweight and thin material, making it easy to transport and install.

- GRC is durable and strong, making it resistant to cracking and other damage.

- GRC is fire-resistant and fireproof, making it a safe choice for buildings.

- GRC has acoustic absorption properties, making it a good choice for buildings in noisy areas.

- GRC is flexible and moldable, making it possible to create complex shapes.

Types of GRC

There are several different types of GRC, each with its own unique properties and applications. Some of the most common types of GRC include:

- Sprayed GRC: Sprayed GRC is a type of GRC that is applied to a surface using a spray gun. Sprayed GRC is often used for cladding and other applications where a thin, lightweight material is required.

- Precast GRC: Precast GRC is a type of GRC that is cast in a mold. Precast GRC is often used for architectural precast concrete and other applications where a strong, durable material is required.

- Extruded GRC: Extruded GRC is a type of GRC that is extruded through a die. Extruded GRC is often used for cladding and other applications where a long, thin material is required.

Conclusion

GRC is a versatile material that can be used in a variety of applications. Its unique properties make it a good choice for buildings in a variety of climates and environments.

Citations:

- International Glassfiber Reinforced Concrete Association (GRCA)

- Glass Fiber Reinforced Concrete (GFRC) – Wikipedia

The manufacturing process of GRC and quality control

From its inception, GFRC has undergone rigorous testing processes to ensure its quality and performance. International organizations like ASTM (American Society for Testing and Materials), PCI (Precast/Prestressed Concrete Institute), and BS (British Standards) have established stringent standards that GFRC must adhere to before being used in construction projects.

The manufacturing process of GRC

There are two main methods for manufacturing GFRC: the sprayed process and the premix process.

Sprayed process

In the sprayed process, a mixture of cement, sand, water, and glass fibers is sprayed onto a mold or formwork. The mixture is compacted using a vibrating screed or roller, and the fibers are distributed evenly throughout the material.

Premix process

In the premix process, the cement, sand, water, and glass fibers are mixed together in a batch mixer. The mixture is then poured into a mold or formwork, and the fibers are distributed evenly throughout the material using a vibrating screed or roller.

Quality control

Quality control is essential in the manufacturing of GFRC to ensure that the final product meets the required specifications. The following quality control measures are typically employed:

- Raw material testing: The raw materials used in the manufacture of GFRC, such as cement, sand, water, and glass fibers, are tested to ensure that they meet the required specifications.

- Mix design testing: The mix design is tested to ensure that it produces a GFRC product that meets the required specifications.

- Product testing: Finished GFRC products are tested to ensure that they meet the required specifications.

Key Takeaways

- The manufacturing process of GFRC ensures the quality and performance of the final product.

- GFRC undergoes rigorous testing processes to ensure that it meets the international standards established by ASTM, PCI, and BS.

- Quality control measures are implemented throughout the manufacturing process to ensure that the final product meets the required specifications.

Relevant Sources:

- International Glassfibre Reinforced Concrete Association (GRCA)

- Glass Fiber Reinforced Concrete (GFRC) – Wikipedia

Sustainability and environmental impact of GRC in construction

Sustainability and environmental impact have become buzzwords in the construction industry as the world grapples with the effects of climate change. GRC (Glass Reinforced Concrete), a greener alternative to traditional precast concrete, offers a unique solution for sustainable construction. Let’s delve into the sustainability benefits of GRC and explore how it can help reduce our environmental footprint.

Reduced embodied energy

Embodied energy refers to the energy consumed during the production, transportation, and installation of a building material. GRC has a significantly lower embodied energy than traditional concrete due to its lighter weight and reduced material content. This means that using GRC can help reduce the overall carbon footprint of a construction project.

Reduced weight

GRC is a lightweight material, weighing up to 80% less than traditional concrete. This reduced weight not only makes it easier to transport and install but also reduces the structural load on buildings, leading to smaller foundations and less energy consumption during construction.

Energy efficiency

GRC panels can be used as exterior cladding, eliminating the need for additional energy-intensive materials such as insulation. GRC’s high thermal mass helps regulate indoor temperatures, reducing the reliance on heating and cooling systems and lowering energy consumption.

Key Takeaways:

- GRC has a lower environmental impact by up to 60% due to its reduced weight and embodied energy.

- GRC is lighter and stronger than concrete, making it a more sustainable option.

- GRC panels can be used for exterior cladding, reducing the need for additional energy-intensive materials.

Citations:

- GRC and Sustainable Building Design

- GRC: The Eco-Friendly Innovation Material That Transformed Construction]

FAQ

Q1: What exactly is GRC (Glass Reinforced Concrete)?

A1: GRC stands for Glass Reinforced Concrete, a versatile building material composed of a mortar blend of hydraulic portland cement, fine aggregate, and alkali-resistant glass fibers.

Q2: What are the primary advantages of using GRC in construction?

A2: GRC offers multiple benefits, including lightweight and thin design, enhanced durability and strength, fire resistance, acoustic absorption, and flexibility in molding.

Q3: Where is GRC commonly employed in construction projects?

A3: GRC finds applications in exterior building façade panels, architectural precast concrete, cladding, renovation projects, and foundations.

Q4: Are there recognized standards for GRC testing and validation?

A4: Yes, GRC undergoes quality assessments following standards such as ASTM, PCI, and BS to ensure its fire resistance, weather resistance, durability, and stiffness.

Q5: Can GRC contribute to sustainable building design and construction?

A5: Yes, GRC showcases a lower environmental footprint compared to traditional precast concrete due to its reduced weight and embodied energy, making it a more sustainable choice for building facades and other architectural elements.

- Finishes For Butcher Block Counters: Choosing The Right Food-Safe Option - December 28, 2025

- Kitchen Countertop Ideas: Find the Perfect Surface for You - December 27, 2025

- Stove Backsplash Design: Ideas to Elevate Your Kitchen Style - December 26, 2025