Embark on a detailed exploration of [Hazards and Control Measures in Construction Sites: A Comprehensive Guide]. With an emphasis on identifying and managing potential risks, this guide will equip you with a comprehensive understanding of hazard control in construction.

Key Takeaways: Hazards and Control Measures in Construction Sites

- Prioritize worker safety by identifying and mitigating potential hazards.

- Train workers on safety best practices and ensure certification.

- Conduct thorough risk assessments to identify potential risks and implement control measures.

- Establish clear entry and exit points to ensure safety during movement.

- Store chemicals safely and adhere to environmental regulations to protect workers.

Hazards and Control Measures in Construction Sites: A Comprehensive Guide

Introduction:

Construction sites are inherently hazardous environments. As a seasoned safety professional, ensuring worker safety is paramount. This guide will provide a comprehensive understanding of common hazards and control measures in construction sites, empowering you to create a safe and compliant work environment.

Hazard Identification and Control

The key to mitigating hazards in construction sites lies in proactiveness. You must methodically identify and assess potential risks, and then implement effective control measures:

-

Identify Hazards: Conduct thorough inspections to identify hazardous conditions, such as fall risks, electrical hazards, and chemical exposure.

-

Assess Risks: Evaluate the severity and likelihood of each hazard to determine its potential impact on workers.

-

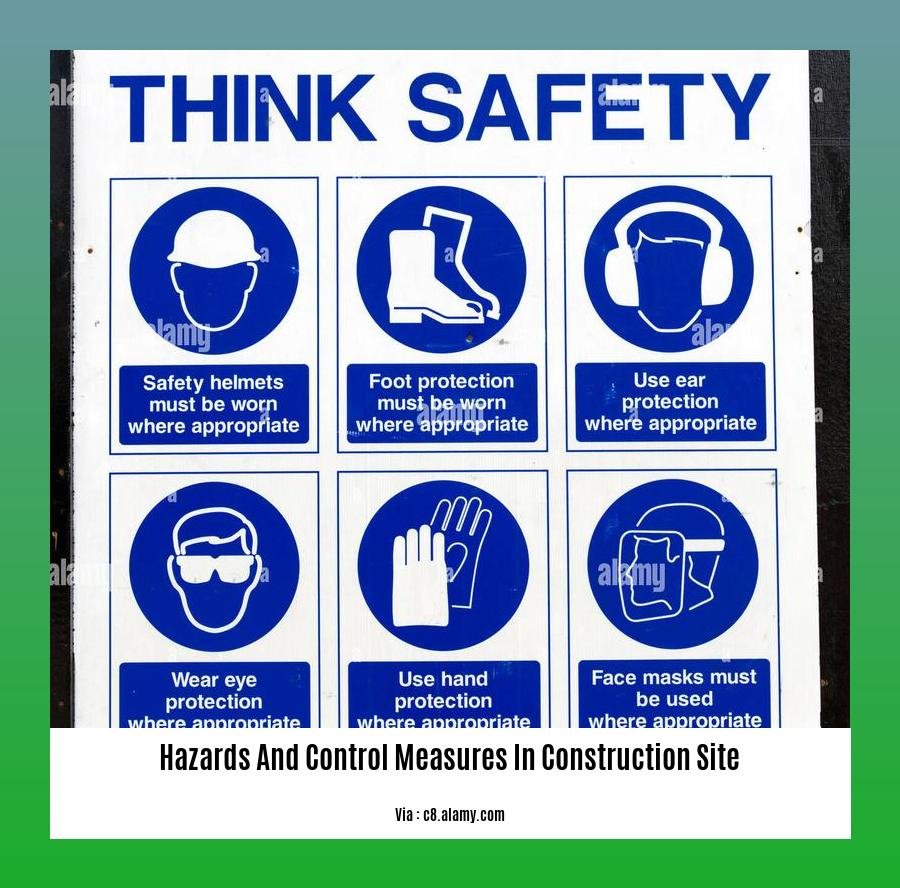

Select Control Measures: Choose appropriate measures to eliminate or minimize identified risks. This may include engineering controls (e.g., guardrails), administrative controls (e.g., training), or personal protective equipment (e.g., safety helmets).

-

Implement Controls: Put control measures in place and ensure they are effectively implemented and maintained.

Common Hazards in Construction Sites

Construction sites present a wide range of hazards. Here are some of the most common:

- Falls from Height: Unprotected edges, open stairwells, and poor housekeeping can lead to serious fall injuries.

- Electrical Hazards: Exposed wires, faulty equipment, and improper grounding can cause electrocution.

- Chemical Exposure: Exposure to hazardous chemicals, such as solvents and paints, can cause respiratory or skin irritation.

- Machinery Hazards: Unguarded machinery, improper use, and lack of training can result in crush injuries, amputations, or electrical shocks.

- Noise: Prolonged exposure to excessive noise levels can damage hearing.

- Vibration: Prolonged exposure to vibration from equipment can cause musculoskeletal disorders.

Control Measures for Common Hazards

Falls from Height:

- Install guardrails and safety nets.

- Use ladders and scaffolds safely.

- Provide fall arrest systems and training.

Electrical Hazards:

- Use properly grounded equipment.

- Inspect cords and wires regularly.

- Train workers on electrical safety.

Chemical Exposure:

- Use proper ventilation and respiratory protection.

- Store chemicals safely and correctly.

- Train workers on chemical handling.

Machinery Hazards:

- Install machine guards and protective devices.

- Provide operator training and certification.

- Establish clear operating procedures.

Noise:

- Use hearing protection devices.

- Limit exposure time to noisy areas.

Vibration:

- Use anti-vibration tools and techniques.

- Limit exposure time to vibrating equipment.

Conclusion:

By understanding the various hazards and control measures in construction sites, you can create a safe and compliant work environment. Remember, safety is not an option but a responsibility. Prioritizing safety practices will not only protect your workers but also contribute to a productive and efficient construction project.

If you are planning a boundary wall for your property and are looking for a way to calculate the cost, then look no further! our boundary wall construction cost calculator is exactly what you need.

Looking for detailed information on boundary wall construction? Our comprehensive guide on boundary wall construction details covers everything you need to know.

Constructing a brick chimney? Get expert guidance with our detailed article on brick chimney construction details.

Need help finding reputable bridge construction companies in India? Check out our directory of bridge construction companies in india.

Searching for bridge construction companies near your location? Explore our curated list of bridge construction companies near me.

Planning a house construction project? Utilize our advanced budget calculator for house construction to estimate costs effectively.

Prioritizing safety in construction? Enhance your knowledge with our comprehensive guide on health and safety in construction environment level 1.

Electrical Hazards and Prevention

Key Takeaways:

- Prioritize Electrical Safety: Minimize risks by establishing clear safety protocols and guidelines.

- Train and Educate Workers: Empower workers with comprehensive training on electrical hazards and prevention measures.

- Utilize Hazard Identification Techniques: Conduct thorough inspections to detect potential electrical hazards and develop targeted control measures.

Precautionary Steps for Electrical Hazard Prevention:

- Lockout/Tagout: Isolate and de-energize circuits to prevent accidental contact with live wires.

- Electrical Grounding: Establish proper grounding systems to ensure the safe flow of electricity and prevent shock hazards.

- Arc Flash Protection: Provide suitable protective clothing and equipment for workers performing welding or electrical maintenance tasks.

- Safe Use of Power Tools: Train workers on the proper handling and use of power tools to minimize the risk of electrical shocks or injuries.

- Electrical Equipment Inspection and Maintenance: Regularly inspect and maintain electrical equipment to ensure it’s in good working condition.

Emergency Preparedness for Electrical Hazards:

- Fire Extinguishers: Ensure the availability of appropriate fire extinguishers specifically designed for electrical fires.

- Designated Escape Routes: Establish clear and well-marked escape routes in case of an electrical emergency.

- Emergency Response Training: Train employees on emergency response procedures, including how to report electrical hazards and administer first aid.

Citations:

- Electrical Hazards: Importance & Examples

- Electrical Hazards On Construction Sites & How To Prevent Them

Confined Space Hazards and Control

Key Takeaways:

- Confined spaces pose unique risks to workers, including falls, electrical hazards, toxic atmospheres, and poor lighting.

- Proper planning, safety measures, and training are crucial to prevent accidents and injuries.

- Follow permit authorization and isolation procedures to ensure the space is safe for entry.

- Conduct gas testing to confirm the absence of harmful gases and provide adequate ventilation.

- Provide appropriate PPE, including confined space entry cards and H2S gas monitors.

- Have an attendant present with an entry sheet and communication device.

- Ensure proper lighting and illumination for clear visibility.

- Display warning signs at the entry point and provide proper access.

Common Confined Space Hazards:

- Atmospheric Hazards: Toxic gases (e.g., carbon monoxide, hydrogen sulfide), combustible gases (e.g., methane, propane), and inert gases (e.g., nitrogen)

- Structural Hazards: Falls from height, uneven surfaces, protruding objects

- Electrical Hazards: Exposed wires, faulty equipment, electrical shock

- Mechanical Hazards: Rotating equipment, moving machinery, crushing hazards

- Entanglement Hazards: Confined spaces with limited mobility can increase the risk of entanglement

Control Measures for Confined Space Hazards:

- Authorization and Isolation: Obtain a permit before entry and isolate the space using barricades, line blinding, or blocking.

- Ventilation: Ventilate the space to remove toxic gases and provide fresh air.

- Gas Monitoring: Use gas detectors to continuously monitor the atmosphere for harmful gases.

- PPE: Provide workers with appropriate PPE, including respirators, gloves, and protective clothing.

- Training: Train workers on confined space safety procedures, rescue operations, and equipment use.

Citations:

- Confined Space and Permit-Required Confined Spaces

- Confined Space Entry

Material Handling and Storage Hazards

When working on construction sites, many tasks involve handling and storing materials like equipment, tools, and supplies. If not handled properly, they can lead to accidents. That’s why understanding the risks associated with material handling and storage hazards is crucial to prevent them.

Common Material Handling and Storage Hazards

Awkward postures when lifting heavy items can result in back injuries, strain, or muscle damage.

Extreme temperatures can cause heat exhaustion, heat stroke, or hypothermia, depending on the conditions.

Improperly stacked materials, especially heavy ones, can collapse, leading to damage to equipment and injuries to workers.

Control Measures for Material Handling and Storage Hazards

-

Proper risk assessment: Conduct thorough assessments of materials to identify potential hazards.

-

Safety measures implementation: Implement safety protocols, such as proper lifting techniques, wearing personal protective equipment (PPE) when handling materials, and adhering to safe storage practices.

-

Safety management systems and procedures: Establish comprehensive safety management systems that include regular inspections, training, and documentation of safe material handling and storage practices.

Key Takeaways:

- Material handling and storage hazards are prevalent in construction sites.

- These hazards include awkward postures, excessive load, and extreme temperatures.

- Control measures like risk assessments, safety measures, and safety management systems are essential for hazard prevention.

- Proper handling and storage practices promote a safe work environment.

Sources:

- Material Handling Hazards and Control Measures in Construction Industry

- Materials Handling and Storage]

FAQ

Q1: What are some common hazards present on construction sites?

A1: Construction sites pose a range of hazards, including electrical hazards, material handling hazards, confined space hazards, slips and falls, and exposure to hazardous substances.

Q2: How can electrical hazards on construction sites be prevented?

A2: Electrical hazard prevention measures include lockout/tagout procedures, training and supervision, welding safety, temporary electrical service safety, and the provision of onsite fire extinguishers.

Q3: What steps should be taken to mitigate material handling hazards on construction sites?

A3: Material handling hazards can be controlled through proper risk assessment, implementing safety measures, and establishing safety management systems and procedures.

Q4: What precautions are essential for confined space safety?

A4: Confined space safety requires authorization and isolation, electrical safety, atmosphere control, gas monitoring, worker protection, attendant presence and communication, and proper lighting and ventilation.

Q5: What measures can be implemented to reduce the risk of slips and falls on construction sites?

A5: Measures to prevent slips and falls include maintaining clean and safe work areas, providing proper footwear and fall protection equipment, and ensuring adequate lighting.

- Island Cabinets: Building Your Own Kitchen Space with Stock Options - October 18, 2025

- Double Kitchen Island: Design Ideas for Cooking and Socializing - October 17, 2025

- Double Island Kitchen Ideas: Design Your Dream Cooking Space - October 16, 2025