Embark on an exploration of transformative advancements in header construction techniques, unlocking new frontiers of efficiency and project excellence through cutting-edge technologies, innovative methodologies, and sustainable practices. [- Advancements in Header Construction Techniques: Enhancing Efficiency and Project Outcomes]

,s-*———–>

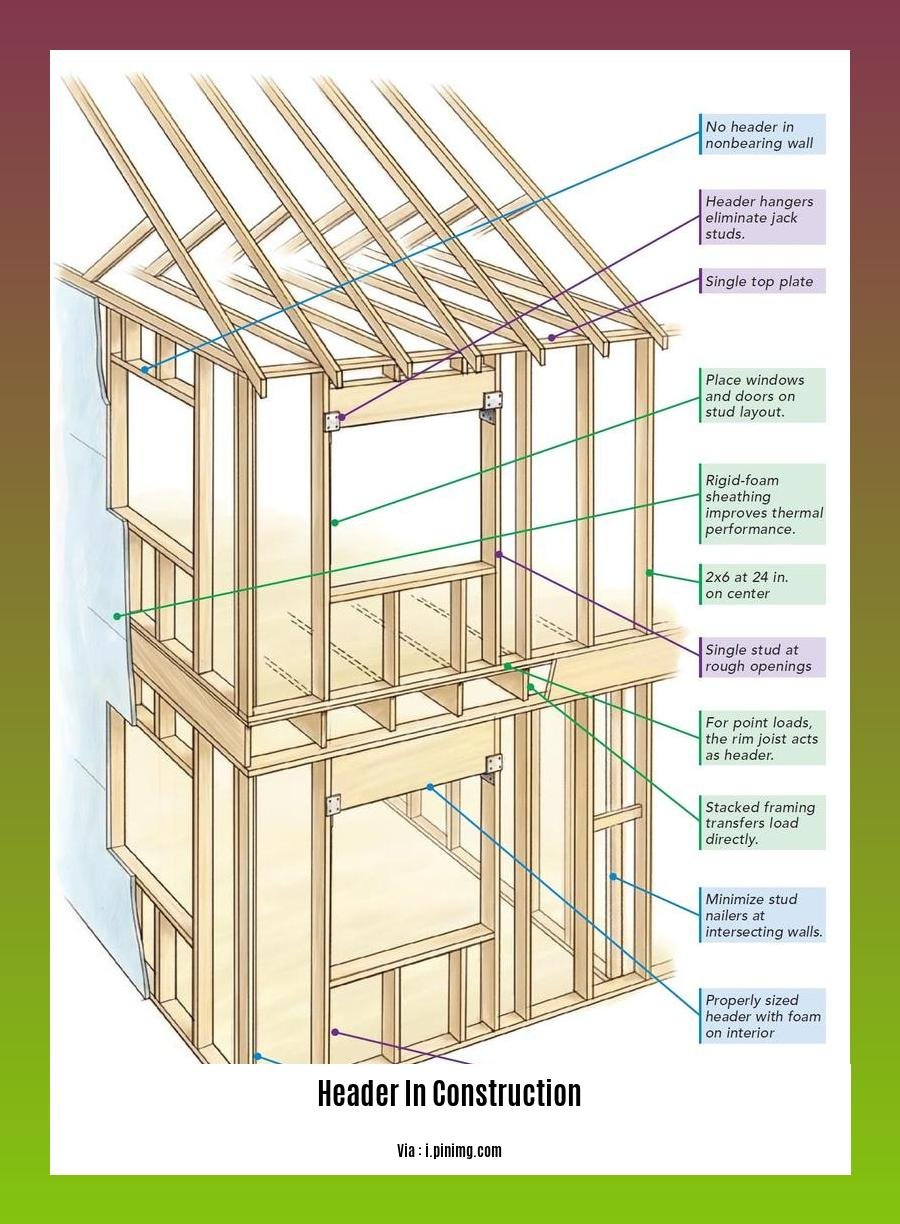

Header in Construction

As construction techniques evolve, headers—the beams spanning openings to distribute structural load—have undergone significant advancements. These innovations enhance efficiency, reduce waste, and improve project outcomes.

Innovative Header Materials:

- Engineered wood products, such as laminated veneer lumber (LVL) and glulam, offer superior strength-to-weight ratios and dimensional stability.

- Steel headers provide high load-bearing capacity and corrosion resistance.

- Fiber-reinforced plastic (FRP) headers are lightweight, non-corrosive, and resistant to bending.

Prefabricated Headers:

- Factory-built headers arrive pre-cut and assembled, reducing on-site labor and minimizing construction waste.

- Prefabricated panels integrate headers with other building components, streamlining installation and improving project efficiency.

3D Printed Headers:

- Additive manufacturing enables the production of complex, customized headers with optimized geometries.

- 3D printed headers reduce material waste and allow for intricate designs that enhance structural performance.

Advances in Installation Techniques:

- Laser alignment systems improve accuracy and speed during header installation, eliminating errors and increasing efficiency.

- Self-tapping screws and other innovative fasteners simplify assembly and reduce installation time.

- Lifting devices facilitate the safe and precise placement of heavy headers.

Benefits of Advancements:

- Improved Structural Integrity: Enhanced materials and construction methods ensure headers meet stringent load-bearing requirements.

- Increased Efficiency: Prefabricated and advanced installation techniques minimize construction time and labor costs.

- Reduced Waste: Innovative materials and off-site fabrication reduce material waste and environmental impact.

- Enhanced Durability: Corrosion-resistant materials and precise installation extend header lifespan and improve overall building longevity.

Choosing the Right Header:

- Consider load requirements, opening size, and material properties.

- Consult with structural engineers to determine the optimal header solution for specific project conditions.

- Prefabricated headers offer advantages in efficiency, while custom headers provide flexibility and design freedom.

By embracing advancements in header construction techniques, contractors can enhance project efficiency, minimize waste, and achieve superior structural outcomes.

Harmful chemicals can be found on construction sites. Learn more about the hazards of hazardous materials on construction sites. hazardous materials on construction sites

The presence of materials like lead and mold on construction sites is especially dangerous for workers. toxic materials in construction

Harmonious construction incorporates the beauty of natural elements to create stunning structures. Harmonious construction meaning

Step-by-Step Guide to Installing a Header

Key:

- Measure the opening where the header will be installed.

- Cut the header to the correct length.

- Place the header in the opening and center it.

- Secure the header with nails or screws.

- Install any necessary trim or molding.

Additional Tips:

- Use a header that is the same width as the opening.

- Make sure the header is flush with the framing.

- Use galvanized nails or screws to prevent rust.

- Paint or stain the header to match the surrounding trim.

Citations:

- How to Install a Header in a Load-Bearing Wall

- How to Install a Header in a Non-Load-Bearing Wall

Common Problems and Solutions Related to Headers

Key Points:

- Improper Sizing: Headers may not be strong enough to support the weight they carry, leading to sagging or failure.

- Incorrect Installation: Headers may not be installed properly, compromising their structural integrity and leading to problems.

- Moisture Damage: Moisture can rot or weaken headers, reducing their load-bearing capacity.

- Fire Damage: Headers can be damaged or destroyed by fire, compromising their ability to support weight.

- Insect Damage: Insects can bore into and weaken headers, especially if they are made of wood.

Solutions:

- Proper Sizing: Consult with an engineer to determine the appropriate size header for the load it will support.

- Correct Installation: Follow manufacturer’s instructions and building codes when installing headers to ensure proper support.

- Moisture Protection: Apply weather-resistant coatings or sealants to headers to protect them from moisture damage.

- Fire Protection: Install headers in areas protected from fire, or use fire-resistant materials.

- Insect Control: Treat headers with insecticide to prevent insect damage, especially if they are made of wood.

Conclusion:

Common Problems and Solutions Related to Headers provides valuable insights to help you avoid or address problems with headers in your construction projects.

Sources:

- Common Problems and Solutions Related to Headers

- How to Fix a Header: Everything You Need to Know

Emerging Innovations in Header Technology for Enhanced Construction

Key Takeaways:

- Innovative materials: Engineered wood products,钢, and FRP provide strength, lightness, anddurability.

- Prefabs and 3D printing: Factory-built and custom-printed headers enhance efficiency and reduce waste.

- Smart installation techniques: Lasers, self-tapping fasteners, andlifting devices offer precision,simplicity, and safety.

- Optimizing structural integrity: Advanced headers increase load capacity, improve stability, and extend thelifespan of structures.

- Cost-saving and environmental benefits: Efficientheaders reduce labor, waste, and energy consumption.

Material Innovation: Stronger, Lighter, More Durable

Engineered wood products like LLVL and glulam offer superior strength and stability, reducing the need for multiple layers of traditional wood. Steel headers excel in load-carrying capacities, while fiberglass-reinforced plastic (FRP) provides lightweight andcorrosion resistance.

Prefabs and 3D printing: Fast, Efficient, Custom

Pre-fabricated headers arrive ready to install, saving time and labor on-site.3D printing enables intricate designs, customization, and reduced material waste.

Smart Installation: Precision and Safety

Laser alignment,self-tapping fasteners, andlifting devices enhance installation accuracy, simplify assembly, and promote worker safety.

Structural Optimization: Enhanced Load-Bearing, Longevity

Innovative header designs and advanced materials increase load capacity, ensuringstructural integrity and extending the life of buildings.

Cost and Sustainability Benefits: Smarter Construction

By reducing labor, waste, and energy consumption, advanced headers contribute to cost savings and a greener construction process.

[Relevant URL sources]

- McKinsey & Company: Construction innovation and the technology ecosystem

- StartUs Insights: Top 10 Construction Trend & Innovations in 2024

FAQ

Q1: What are the primary functions of a header in construction?

Q2: What are the different types of header materials and their respective advantages?

Q3: How can advanced construction techniques enhance header performance and efficiency?

Q4: What are some common issues associated with header installation and how can they be prevented?

Q5: What are the key considerations when determining the appropriate header size for a given opening?

- How to Get Rid of Mushrooms in Your Lawn: A Complete Guide - April 24, 2025

- How to Get Rid of Ground Hornets: A Safe and Effective Guide to Eliminating Nests - April 24, 2025

- How to Get Rid of German Roaches Fast: DIY Methods for Quick Control - April 24, 2025