Welcome to the ultimate guide for headwall construction! As a seasoned construction professional specializing in this field, I’m excited to share my expertise and provide you with [10 Essential Tips for Headwall Construction].

Key:

- Definition of headwall

- Purpose of headwalls

- Use of wing walls

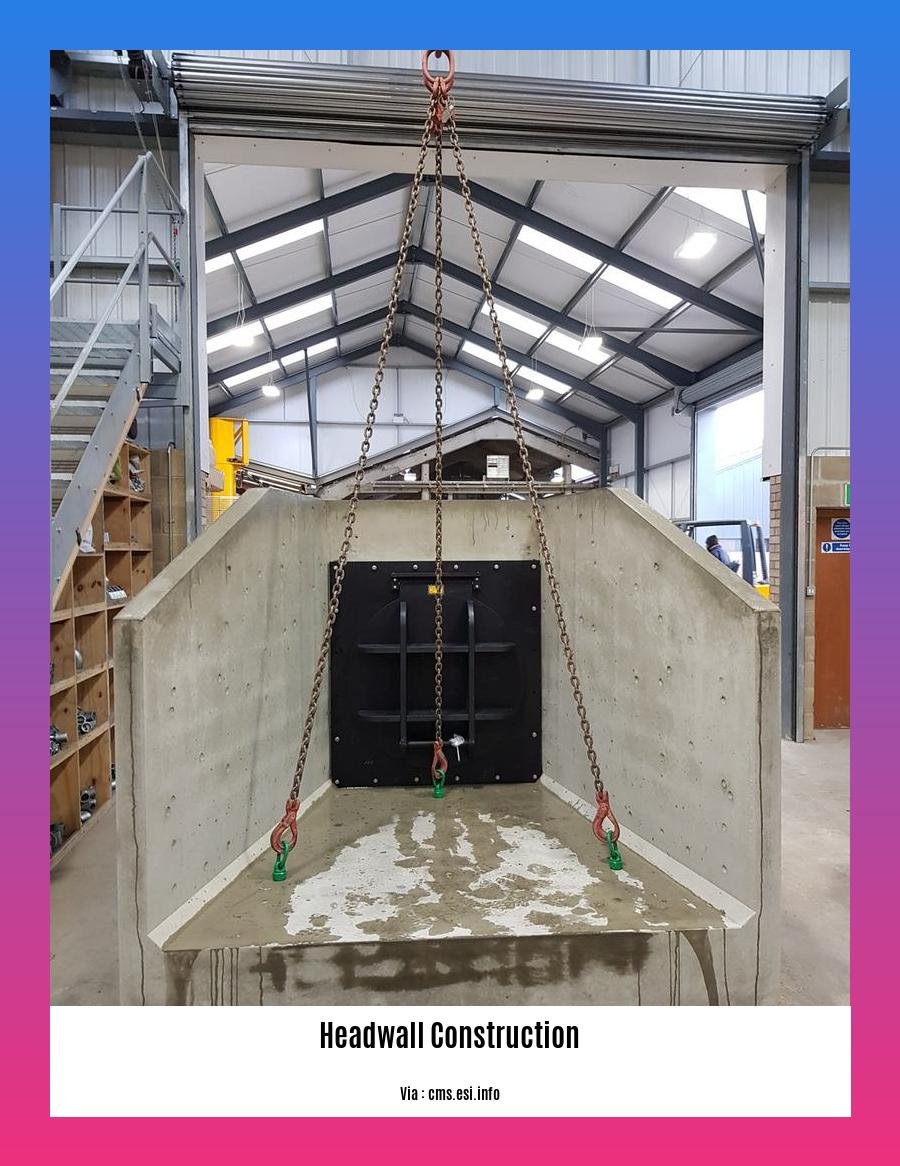

- Benefits of precast headwalls

Headwall Construction: A Comprehensive Guide

Building a headwall requires careful planning and precise execution to ensure structural integrity and longevity. Here’s a comprehensive guide to help you construct a headwall that meets industry standards and withstands the test of time:

1. Plan meticulously

Before you begin construction, it’s crucial to plan meticulously. Determine the size, shape, and location of your headwall. Consider the flow of water, soil conditions, and any potential obstructions. Proper planning will save you time and effort in the long run.

2. Prepare the foundation

Excavate the area where the headwall will be built, ensuring a solid foundation. Compact the soil to prevent settlement and create a level base. Installing a crushed stone base will provide additional stability and drainage.

3. Build the formwork

Construct formwork using wood or metal panels to create the shape of the headwall. Ensure that the formwork is sturdy and securely fastened to prevent concrete leaks. Leave openings for any pipes or conduits that will pass through the headwall.

4. Reinforce with rebar

Reinforce the headwall with rebar to enhance its strength and durability. Position the rebar according to the engineered design to resist the forces exerted by water flow.

5. Pour the concrete

Use high-quality concrete specifically designed for headwall construction. Pour the concrete into the formwork in layers, vibrating it to remove any air pockets. Smooth the surface and screed it to achieve a level finish.

6. Cure the concrete

Allow the concrete to cure properly for several days. Keep it moist by covering it with plastic or burlap and sprinkling it with water. Curing allows the concrete to gain strength and achieve its full potential.

7. Backfill and compact

Once the concrete has cured, backfill the area around the headwall with soil. Compact the soil in layers to ensure stability and prevent erosion.

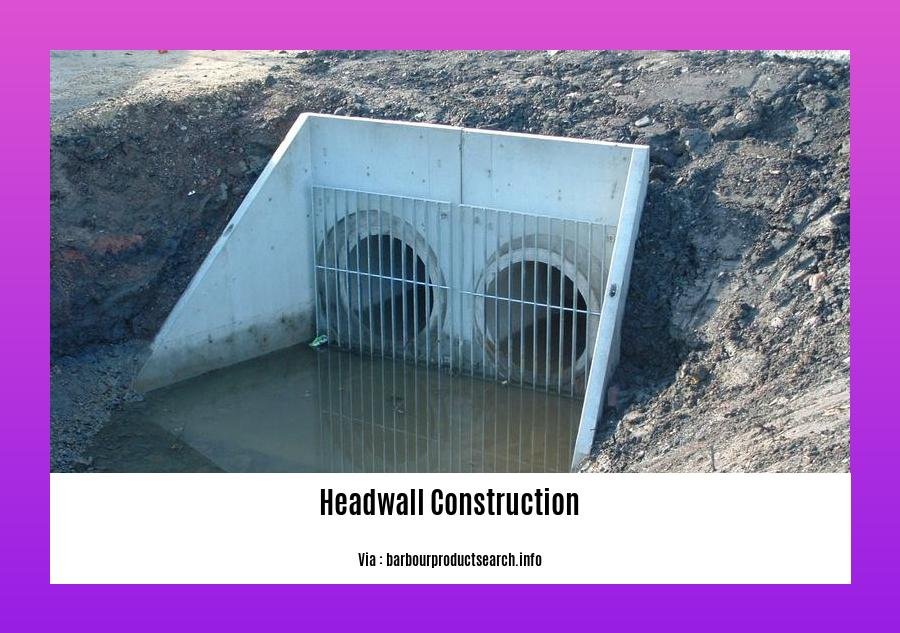

8. Install wing walls (optional)

Wing walls are often used in conjunction with headwalls to divert water flow. They are typically made of concrete and can be attached to the headwall to extend its reach. Wing walls help prevent erosion and improve the overall functionality of the headwall.

9. Seal the joints

Seal any joints between the headwall, wing walls, and pipe connections to prevent water infiltration. Use a flexible sealant or caulk that is compatible with the materials used in your headwall construction.

10. Monitor and maintain

Regularly inspect your headwall for any signs of damage or erosion. Perform maintenance as needed, such as repairing cracks or cleaning debris from the joints. Proper maintenance will ensure the longevity and effectiveness of your headwall.

Curious about the benefits of letting children engage in imaginative construction play? Discover the myriad of developmental advantages associated with this activity by following the link here.

In addition to exploring the advantages of construction play, you may also be interested in learning about the rewarding aspects of a career in construction. Click here to delve into the fulfilling opportunities and benefits this industry offers.

Headwall Construction Techniques

Greetings, my fellow construction enthusiasts! Today, I’m diving deep into the world of Headwall Construction Techniques. Headwalls, those critical structural components, play a pivotal role in managing water flow and preventing erosion, making them indispensable for any infrastructure project.

Key Takeaways:

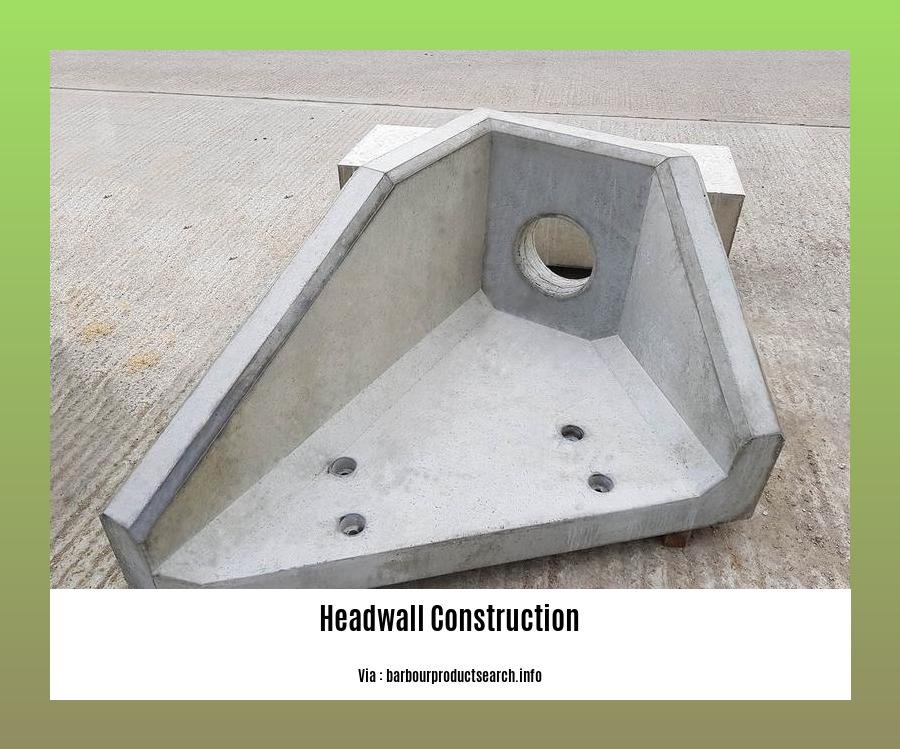

- Headwalls are vertical structures that support bridges or culverts, preventing erosion.

- They are typically made of concrete and must withstand the forces of water flow.

- Component types include wingwalls, headwall aprons, and endwalls.

- Design considerations include soil conditions, drainage patterns, and traffic loads.

- Ensure proper planning, foundation preparation, formwork, reinforcement, concrete pouring, curing, backfilling, and sealing for successful headwall construction.

1. Laying the Foundation: A Solid Base

Delving into the intricacies of Headwall Construction Techniques, we begin with the foundation, the very bedrock of any robust structure. Excavating the designated area to the precise depth and dimensions, we meticulously compact the soil to create a stable and supportive base. Then, we reinforce this base with a layer of crushed stone, providing an additional layer of durability and drainage.

2. Formwork: Shaping the Headwall

Next, we craft the formwork, the mold that will shape our headwall. Using precision and attention to detail, we assemble wooden or metal panels into the desired shape and size. This formwork serves as a guide for the concrete, ensuring its accurate placement.

3. Reinforcement: Strength in Numbers

To enhance the strength and durability of our headwall, we strategically position rebar within the formwork. These steel rods work in harmony with the concrete, resisting tensile forces and ensuring the headwall can withstand the rigors of its environment.

4. The Concrete Pour: A Critical Moment

With precision and care, we pour high-quality concrete into the formwork, filling every nook and cranny. Utilizing a vibrator to eliminate air pockets, we achieve a smooth and dense concrete surface, ensuring the headwall’s integrity.

5. Curing: Time for Strength

After the concrete pour, we nurture our creation by covering it and regularly sprinkling it with water. This curing process allows the concrete to gradually gain strength and reach its full potential.

6. Backfilling: Securing the Headwall

Once the concrete has cured, we backfill the area around the headwall with soil. Compacting this soil in layers ensures the headwall remains securely in place, providing long-lasting stability.

7. Sealing: Preventing Water Infiltration

To prevent water infiltration, we apply a flexible sealant or caulk to all joints and seams. This meticulous attention to detail ensures the headwall’s longevity and effectiveness.

8. Monitoring and Maintenance: Ensuring Longevity

Regular inspections and timely maintenance are crucial for maintaining the headwall’s integrity. By addressing any potential issues promptly, we prolong its lifespan and preserve its functionality, ensuring it continues to serve its purpose for years to come.

Sources

- Headwalls & Endwalls

- Headwall: Considerations for Design and Construction

Backfilling and Compaction

When building a headwall, Backfilling and Compaction play pivotal roles in ensuring structural stability and longevity. Here’s a concise guide to these essential steps:

Backfilling

- After the headwall is constructed, the excavated space around it needs to be filled with suitable material.

- Select well-draining materials such as coarse sand or crushed stone to prevent water accumulation and potential damage to the headwall.

- Place the backfill in layers, each approximately 6-8 inches thick, to allow for proper compaction.

Compaction

- Compaction is crucial to provide adequate support for the headwall and prevent settlement.

- Use a mechanical compactor, such as a plate compactor or rammer, to achieve the desired density and stability.

- Compact each layer thoroughly, ensuring consistent compaction throughout the backfill area.

Key Takeaways:

- Proper backfilling and compaction are essential for headwall stability and longevity.

- Use well-draining backfill materials and compact in layers.

- Compact each layer thoroughly to achieve the desired density and support.

Sources:

- Backfilling in Foundation

- An Intro to Fill and Backfill for Structures

Headwall Maintenance and Repair

Ensuring the longevity and functionality of your headwalls is crucial for maintaining efficient water flow and preventing costly repairs. Here are some essential tips for effective Headwall Maintenance and Repair:

Importance of Inspections

Regular inspections are vital for detecting and addressing minor issues before they escalate into major problems. Inspect headwalls for cracks, erosion, joint damage, and debris accumulation. Prompt attention to repairs can extend the life of your headwalls significantly.

Debris Control

Headwalls are prone to debris accumulation, which can obstruct water flow and cause backups. Regularly remove debris around and inside headwalls to prevent blockages and maintain efficient drainage.

Drainage Management

Proper drainage is essential to prevent erosion and structural damage to headwalls. Ensure that the surrounding area slopes away from the headwall to direct water away. Consider installing drainage systems, such as French drains or sump pumps, to control excess water.

Erosion Prevention

Erosion can weaken the foundation of headwalls and lead to collapse. Protect headwalls from erosion by installing riprap or erosion control blankets around the base. Regular monitoring and maintenance of erosion control measures are crucial.

Crack Repairs

Minor cracks in headwalls can be repaired using patching compounds, epoxy, or mortar. For more severe cracks, professional repair or replacement may be necessary. Timely repairs prevent further damage and ensure the structural integrity of the headwall.

Grading

Improper grading can lead to water accumulation and erosion around headwalls. Ensure that the surrounding area is graded to direct water away from the structure and prevent soil erosion. Regular grading and maintenance are essential for long-term performance.

Key Takeaways:

- Regular inspections are crucial for detecting potential issues early on.

- Debris removal prevents blockages and ensures efficient drainage.

- Proper drainage protects headwalls from erosion and structural damage.

- Erosion control measures prevent foundation weakening and collapse.

- Crack repairs maintain structural integrity and prevent further damage.

- Grading ensures proper water flow and prevents erosion.

Citations:

- Headwall Maintenance and Repair: A Guide to Prolonging Headwall Lifespan

- Importance of Headwall Maintenance and Repair for Infrastructure

FAQ

Q1: What is the primary purpose of a headwall in construction?

A1: A headwall is a vertical or sloping structure at the end of a bridge, culvert, or stormwater drainage system that provides support and prevents erosion.

Q2: What materials are commonly used to construct headwalls?

A2: Headwalls are typically made of concrete or precast concrete due to their durability and ability to withstand the forces of water flow.

Q3: What are the different types of headwalls?

A3: There are various types of headwalls, including parallel-sloped, sloped-parallel, vertical, and endwalls, each designed to suit specific site conditions and flow requirements.

Q4: What factors should be considered when designing a headwall?

A4: Design considerations for headwalls include soil conditions, drainage patterns, traffic loads, and the surrounding environment.

Q5: What are the key steps in headwall construction?

A5: The construction process involves excavation, footing installation, headwall placement, backfilling, and compaction to ensure stability and proper drainage.

- 30+ Beautiful Flowers That Start With N (Pictures and Growing Guides) - April 22, 2025

- 40+ Flowers That Start With L: A Comprehensive Guide - April 22, 2025

- 20+ Fabulous Flowers That Start With J: A Complete Guide - April 22, 2025