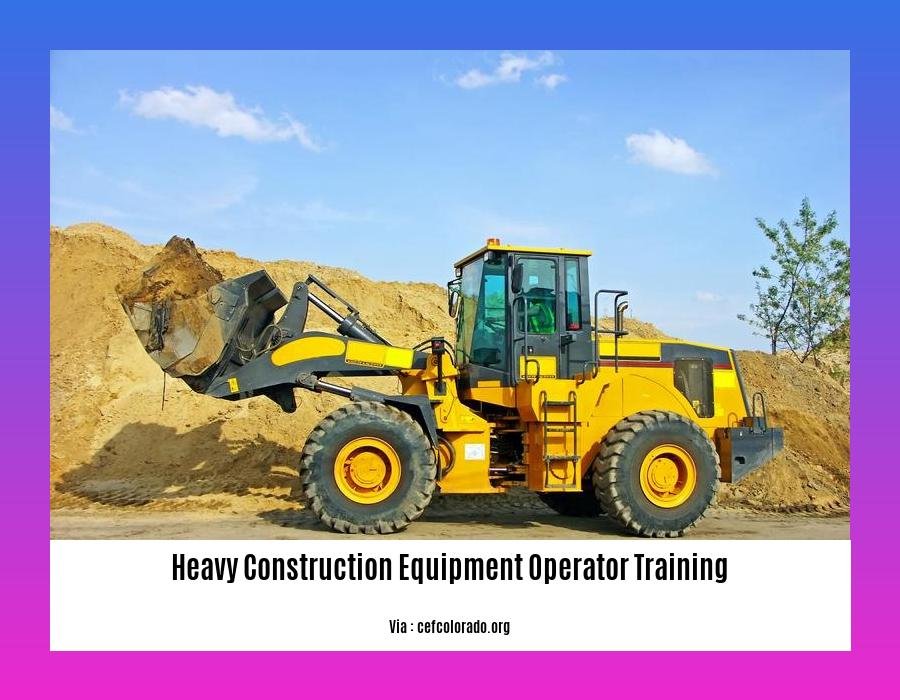

Embark on a journey towards mastering the art of earthmoving with our comprehensive training program, “Heavy Construction Equipment Operator Training: Mastering Earthmoving Mastery.” Delve into the intricacies of operating excavators, bulldozers, and loaders, gaining the expertise to excel in complex construction environments. Our seasoned instructors, with their wealth of experience, will guide you through safety protocols, environmental regulations, and equipment maintenance, ensuring your success as a highly skilled heavy construction equipment operator.

Key Takeaways:

- Education: High school diploma or GED required for apprenticeship or technical school.

- Training: Specialized training from vocational schools, apprenticeships, or on-the-job training.

- Certifications and Licenses: May be required depending on equipment and employer.

- Resume and Professional Development: Continuously update resume and pursue opportunities for learning and skill enhancement.

Heavy Construction Equipment Operator Training

The construction industry relies heavily on skilled professionals who can operate and maintain heavy equipment. If you’re interested in a career as a heavy construction equipment operator, follow these steps to get started:

- Step 1: Obtain Education and Training

Formal training is required for operating heavy machinery safely and efficiently. Consider vocational schools, apprenticeships, or on-the-job training to learn about equipment functions, safety protocols, and maintenance.

- Step 2: Acquire Certifications and Licenses

Depending on your employer and type of equipment, you may need specific certifications or a Commercial Driver’s License (CDL). Stay updated on industry requirements.

- Step 3: Gain Experience

Practical experience is crucial. Join a reputable construction company and work under experienced operators to gain hands-on knowledge and hone your skills.

- Step 4: Enhance Your Resume

Update your resume to highlight your training, certifications, and experience. Network and seek opportunities for continued learning to expand your skillset.

- Step 5: Stay Informed

The construction industry is constantly evolving. Keep up with advancements in equipment technology, safety regulations, and best practices through industry publications and conferences.

Becoming a Master Operator

Mastering heavy construction equipment operation requires a combination of technical expertise and professional attributes:

- Technical Proficiency: Know your machines inside out. Understand their functions, capabilities, and maintenance needs.

- Safety-Conscious: Safety is paramount. Follow established protocols, wear protective gear, and prioritize situational awareness.

- Problem-Solving Mindset: Construction sites present unexpected challenges. Develop problem-solving skills to navigate obstacles efficiently.

- Communication and Teamwork: Collaborate effectively with other operators, supervisors, and project managers to ensure smooth work processes.

With dedication and continuous learning, you can become a highly skilled heavy construction equipment operator, contributing to the success of major infrastructure projects.

When working on a construction site, there are certain high risk activities that workers should be aware of to ensure their safety. For those looking for a construction company that specializes in high-end construction projects, our team of experts can help you achieve your desired results. If you’re in need of a high tech construction company that can provide you with cutting-edge solutions, look no further than our experienced professionals.

Comprehensive Guide to Loader Operation and Material Handling

As an experienced heavy construction equipment operator, I’ve mastered the art of loader operation and material handling. From grading landscapes to hauling heavy materials, loaders are indispensable tools on any construction site. Here’s a comprehensive guide to help you get up to speed.

Loader Operation Basics

- Familiarize yourself with the loader’s controls, including the steering wheel, throttle, brakes, and hydraulic levers.

- Practice maneuvering the loader in both forward and reverse, paying attention to its center of gravity.

- Understand the loader’s capacity and lifting height to avoid overloading or tipping.

Material Handling Techniques

- Use the loader’s bucket to scoop and transport materials like dirt, gravel, and aggregates.

- Position the bucket correctly to maximize the load and minimize spillage.

- Handle materials carefully to prevent damage or injury.

Safety Considerations

- Always wear a seatbelt and proper protective gear while operating a loader.

- Maintain a safe distance from other equipment and personnel.

- Inspect the loader thoroughly before each use to identify any potential issues.

Key Takeaways:

- Master loader controls for safe and efficient operation.

- Practice proper material handling techniques to minimize risks.

- Prioritize safety by following guidelines and wearing protective gear.

Relevant URL Sources

- Construction Equipment Operator Training: A Detailed Guide

- A Beginner’s Guide to Heavy Equipment Operator Training

Effective Maintenance and Strategies for Heavy Equipment

As a seasoned heavy construction equipment operator, I’ve witnessed firsthand the critical importance of effective maintenance and strategies for heavy equipment. When these colossal machines are properly cared for, they not only perform optimally but also ensure safety and longevity on job sites. Here are some key insights I’ve gained over the years:

Conduct Regular Maintenance:

Regular maintenance is the cornerstone of keeping your heavy equipment in tip-top shape. Establish a comprehensive maintenance schedule that addresses:

- Inspection and Inspection: Inspect equipment regularly for leaks, wear, and damage.

- Fluid and Filter Changes: Replace fluids and filters according to manufacturer recommendations.

- Lubrication: Lubricate moving parts to reduce friction and wear.

Use the Right Tools and Lubricants:

Employ the right tools and high-quality synthetic or semi-synthetic heavy-duty oils and grease. They enhance equipment performance and extend component life.

Monitor Equipment Health:

Install condition-monitoring sensors on critical systems. These sensors provide real-time data on temperature, pressure, and vibration, allowing for proactive maintenance and repairs.

Train Your Crew:

Educate your operating crew on proper maintenance techniques. Empowered employees are more likely to identify potential issues early on.

Document and Organize:

Keep detailed maintenance records. This historical data becomes invaluable during troubleshooting and future repairs.

By following these effective maintenance and strategies, you’ll:

- Minimize Downtime: Keep your equipment running smoothly, reducing costly downtime.

- Enhance Safety: Regular maintenance eliminates potential hazards and ensures a safe work environment.

- Improve Efficiency: Well-serviced equipment operates more efficiently, reducing fuel consumption and emissions.

- Extend Lifespan: With proper care, your heavy equipment will last longer, saving you replacement costs.

Key Takeaways:

- Regular maintenance is essential for optimal equipment performance and longevity.

- Use the right tools and high-quality fluids to ensure smooth operation and extend component life.

- Monitor equipment health and train your crew to identify potential issues early on.

- Document and organize maintenance records for future reference.

Sources:

- Maintenance and Troubleshooting Guide for Heavy Equipment Operators

- Heavy Equipment Maintenance Tips From Experienced Pros

Career Advancement Opportunities in Heavy Construction Equipment Operation

From entry-level positions to supervisory roles, the heavy construction equipment operation field offers a diverse range of Career Advancement Opportunities in Heavy Construction Equipment Operation. With the right skills and dedication, you can climb the ladder of success.

Specialize and Certify

As you gain experience, consider specializing in a specific type of equipment, such as excavators, bulldozers, or cranes. Earning certifications and participating in professional development programs will enhance your knowledge and credibility.

Transition to Management

With years of hands-on experience and a strong understanding of construction principles, you can transition into a management role. As a supervisor or foreman, you will oversee operations, manage crews, and ensure project deadlines are met.

Start Your Own Business

If you have a strong entrepreneurial spirit, consider starting your own construction-related business. This could involve renting out heavy equipment, providing specialized services, or becoming a contractor.

Key Features:

- Advancement Path: Equipment training or sales, specialized machinery, construction management, supervisory positions, entrepreneurship

- Skills Required: Specialization, leadership, management

Additional Tips

- Keep abreast of the latest equipment technologies and industry trends.

- Network with other professionals and attend industry events.

- Seek out mentors who can guide your career path.

Relevant Sources:

- 7 Career Progression and Advancement Opportunities for Construction Equipment Operators

- 2022 Construction Equipment Acquisition Trends

FAQ

Q1: What are the key components of heavy construction equipment maintenance?

Q2: How does preventive maintenance benefit heavy construction equipment operations?

Q3: What are the different types of heavy construction equipment training available?

Q4: What career advancement opportunities are available for heavy construction equipment operators?

Q5: What skills are essential for success as a heavy construction equipment operator?

- How to Get Rid of Mushrooms in Your Lawn: A Complete Guide - April 24, 2025

- How to Get Rid of Ground Hornets: A Safe and Effective Guide to Eliminating Nests - April 24, 2025

- How to Get Rid of German Roaches Fast: DIY Methods for Quick Control - April 24, 2025