Welcome to the comprehensive guide on Highway Construction Steps. In this article, you’ll embark on a detailed journey through each crucial stage of highway construction, providing valuable insights into the complexities of this vital infrastructure development process.

Key Takeaways:

- Planning and design dictate the course and work scope.

- Excavation clears the path by removing obstacles.

- Structural elements (embankments, tunnels, bridges) enhance safety and accessibility.

- Fine grading ensures a smooth surface.

- Base aggregate provides a stable foundation.

- Paving with asphalt or concrete creates the final surface.

- Inspections and maintenance guarantee safety and longevity.

Highway Construction Steps: A Step-by-Step Guide

Navigating the complexities of highway construction steps requires a comprehensive understanding of the entire process. From planning to completion, these critical stages ensure the safety, efficiency, and durability of our roadways.

1. Planning and Design

The foundation of any highway construction project lies in meticulous planning and design. Engineers meticulously analyze traffic patterns, environmental impact, and geological conditions to determine the ideal route and construction methods.

2. Site Preparation

Before construction can commence, the site must be prepared. This involves clearing vegetation, leveling the ground, and excavating areas for embankments, tunnels, and bridges. Proper site preparation sets the stage for a stable and well-drained roadway.

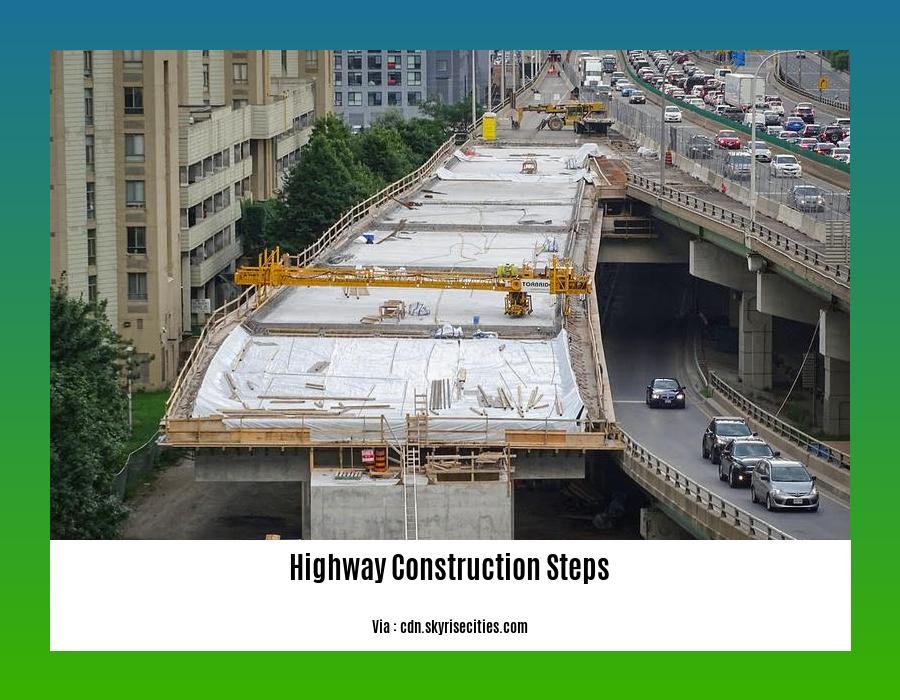

3. Earthwork

Earthwork encompasses the construction of embankments, the structures that elevate the highway above the surrounding terrain. Engineers carefully compact soil and other materials to create a solid foundation for the road surface.

4. Drainage Systems

Effective drainage is paramount for highway safety. Engineers design and install drainage systems to channel water away from the road surface, preventing flooding and erosion.

5. Subbase and Base

Beneath the asphalt or concrete surface lies the subbase and base layers. These layers provide support and stability to the road surface, distributing the weight of vehicles evenly.

6. Paving

The final step in highway construction is paving. Engineers expertly apply asphalt or concrete to create a smooth, durable surface that can withstand heavy traffic loads.

7. Finishing Touches

Once the road surface is complete, final touches such as guardrails, signage, and pavement markings are installed to ensure the safety and visibility of the highway.

Throughout these highway construction steps, engineers adhere to strict quality control measures to ensure the durability and longevity of the roadway. By following these steps, we create highways that facilitate efficient and safe travel for years to come.

Find everything you always wanted to know about highway construction but were afraid to ask when you read our highly detailed article on the topic. To learn the complete highway construction companies in india, we highly recommend you continue reading.

Do you want to know more about the highway construction process? Then, this link is the perfect place to get started! It covers all the basics along with information about highway construction procedure for a beginner.

Construction: Decoding Highway Construction Steps

Key Steps:

- Planning: Set the project’s objectives, budget, and permits; conduct environmental impact studies and determine road design.

- Project Development: Design the highway, including geometry, materials, and drainage systems; acquire right-of-way.

- Final Design: Prepare detailed construction drawings and specifications; finalize alignment and drainage for safety and efficiency.

Construction:

Preliminary Planning:

– Establish construction schedule, equipment, and materials.

Demolition and Removal:

– Clear the site of existing structures and vegetation.

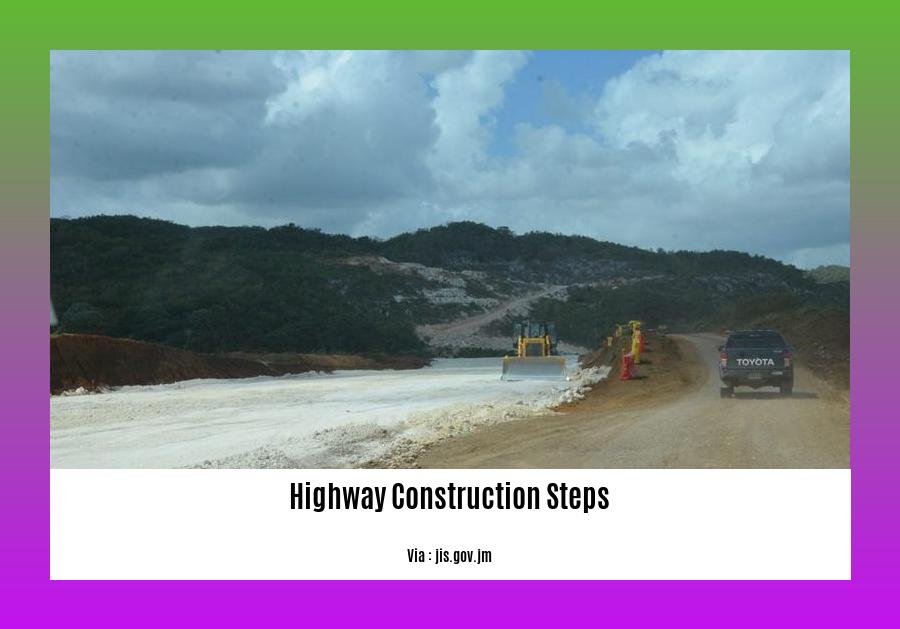

Ground Leveling:

– Excavate and grade the subgrade to the desired elevation.

Sub Base:

– Lay out a stable and draining sub base layer.

Binder Layer:

– Apply a layer to bond the sub base and asphalt.

Asphalt:

– Pave the surface with asphalt for a smooth and durable driving surface.

Transitions:

– Connect the new road to existing roads for seamless travel.

Final Inspection:

– Review the completed project to ensure it meets all specifications.

Sources:

– Road Construction: Step-by-Step Process

– What are the steps in a road construction project?

Inspection and Quality Control

Ensuring the quality and safety of highway infrastructure is paramount. Traditional manual inspection methods are inefficient, subjective, and error-prone. To enhance accuracy and efficiency, integrating Building Information Modeling (BIM) with quality standards is crucial. The road construction industry in China exemplifies the significance of rigorous quality control measures.

Importance of Inspection and Quality Control in Highway Construction

Inspection involves examining the construction process and identifying deviations from specifications. Quality Control ensures adherence to standards and regulations throughout the project lifecycle, from materials sourcing to final delivery. Effective Inspection and Quality Control practices guarantee durable, safe, and cost-effective highway infrastructure.

Integrating BIM for Inspection and Quality Control

BIM provides a digital representation of the highway construction project. By incorporating 3D models, construction plans, and quality standards into the BIM platform, inspectors can:

- Visualize the project’s progress and identify potential issues early on.

- Track and document inspections in real-time, reducing errors and enhancing accountability.

- Simulate construction processes and test different scenarios, optimizing quality and reducing delays.

Key Takeaways:

- Inspection and Quality Control are essential for ensuring the safety, durability, and cost-effectiveness of highway infrastructure.

- Traditional manual inspection methods have limitations; integrating BIM with quality standards improves accuracy and efficiency.

- BIM enables visualization, real-time documentation, and scenario testing, enhancing Inspection and Quality Control practices.

Citations:

- Integrating BIM and Quality Standards for Highway Construction Inspection

- Strategies for Strengthening Highway Construction Testing and Inspection

Project Completion and Acceptance

As your project nears completion, it’s time to ensure a seamless acceptance process. Here’s a step-by-step guide to navigate this crucial phase:

1. Final Inspection:

Conduct a thorough walkthrough with all stakeholders to identify any outstanding items or deficiencies. Address these promptly to ensure project alignment with specifications.

2. Documentation Review:

Gather all project documentation, including construction drawings, permits, and inspection reports. Verify that these documents accurately reflect the constructed facility.

3. Punch List Generation:

Create a list of any remaining minor issues that require attention. Assign responsibilities and timelines for resolution.

4. Substantial Completion:

Once the punch list is complete, declare the project substantially complete. This signifies the transfer of ownership to the client, assuming they have approved the facility.

5. Final Payment Certification:

Issue a formal certificate of substantial completion, outlining the total contract cost and any outstanding payments.

6. Warranty Period:

The warranty period typically begins from the date of substantial completion. Ensure clear communication with the client regarding the scope and duration of the warranty.

7. Project Closeout:

Finalize all project documentation, including change orders, invoices, and any remaining punch list items. Archive all relevant documents for future reference.

Key Takeaways:

- Final inspection ensures the project meets specifications.

- Thorough documentation provides a record of the constructed facility.

- Prompt punch list resolution maintains project momentum.

- Substantial completion transfers ownership and begins warranty period.

- Payment certification ensures financial closure.

- Project closeout secures documentation and accountability.

Relevant URL Sources:

- Construction Project Completion and Acceptance: A Step-by-Step Guide

- Project Completion and Acceptance in Construction: A Comprehensive Overview

FAQ

Q1: What are the key steps involved in highway construction?

A1: Highway construction typically involves planning, project development, final design, and construction phases, which include site preparation, base and subbase construction, and pavement construction.

Q2: What is the process for planning a highway construction project?

A2: Planning involves establishing project goals, scope, and funding, conducting environmental impact assessments, and determining alignment, grade, and drainage.

Q3: What are the considerations for final design in highway construction?

A3: Final design involves preparing detailed construction drawings and specifications, optimizing alignment and drainage to ensure safety and efficiency.

Q4: What are the different types of materials used in highway construction?

A4: Highway construction materials include asphalt, concrete, crushed stones, gravel, and various soil materials for embankments and subgrades.

Q5: How is quality control ensured in highway construction?

A5: Quality control in highway construction involves inspection, testing, and documentation to ensure adherence to design specifications and industry standards, promoting safety and durability.

- Pontoon Boat Seat Covers: The Ultimate Guide to Protection & Buying - April 17, 2025

- Covers for Pipework: A Complete Guide to Materials, Installation & More - April 17, 2025

- Dog Patio Door Inserts: A Comprehensive Guide to Choosing & Installing - April 17, 2025