This guide demystifies LVL span charts, empowering you to choose the perfect beam for your project, whether it’s a l-shaped shower rod installation, a deck, roof, or brainstorming on large white boards. We’ll explain the essentials, avoiding jargon, and focusing on practical application.

Understanding LVL and Its Advantages

What is LVL?

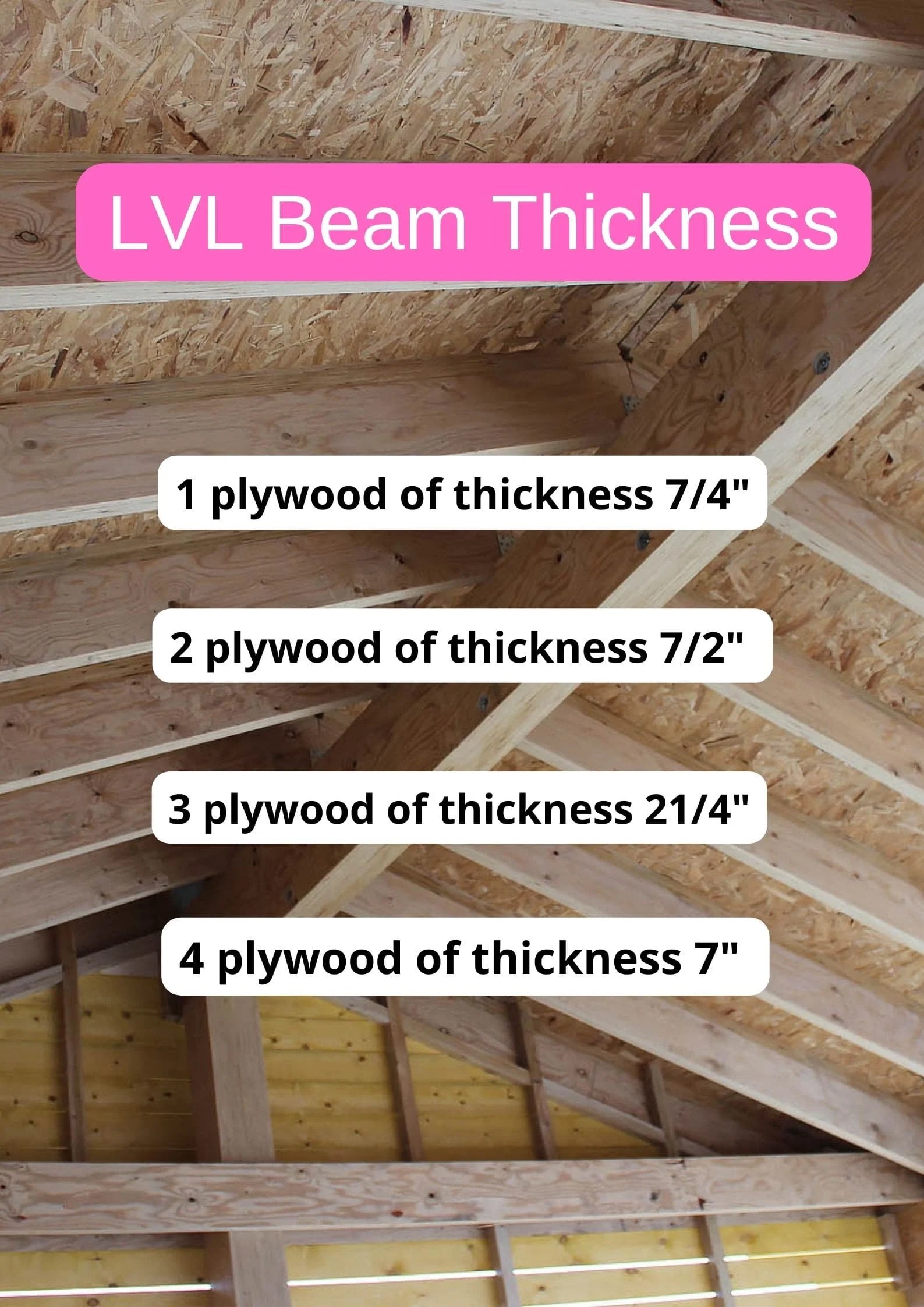

LVL (Laminated Veneer Lumber) is engineered wood made from thin, layered wood sheets glued under pressure. This creates exceptional strength, stiffness, and resistance to warping, making LVL ideal for load-bearing applications like beams, headers, and rim boards. It’s likely a better choice than traditional lumber for long, straight beams needing to support substantial weight.

Decoding LVL Span Charts

Why Use a Span Chart?

A laminated veneer lumber span chart eliminates guesswork when selecting beam sizes. It indicates the maximum distance (span) a beam can safely bridge between supports, based on factors like size, grade, and load. This helps ensure your project’s structural integrity.

How to Interpret a Span Chart

LVL span charts might seem complex initially, but they’re quite straightforward. They typically present data on beam size, LVL grade, load type (dead, live, snow), and the corresponding maximum allowable span. Some charts also include deflection limits (how much the beam can bend). Key components include:

- Beam Size: Nominal dimensions (e.g., 2×10, though actual dimensions are often slightly smaller). The depth of the beam is particularly critical for spanning capacity. A deeper beam generally spans further.

- LVL Grade: LVL comes in different grades, indicating strength and stiffness. Higher grades handle heavier loads.

- Load: The total weight the beam supports: dead load (the structure’s weight), live load (people, furniture), and snow load (where applicable). Accurately calculating the total load is probably the most critical step in selecting the right beam.

- Span: The distance between supporting points (walls, posts).

Finding Reliable Span Charts

Always consult reputable LVL manufacturers like Weyerhaeuser or LP Building Solutions for accurate, up-to-date span charts. Often, they provide helpful online span calculators as well. Avoid unreliable or outdated sources.

Factors Beyond the Chart

While the span chart provides vital information, other crucial factors influence beam selection:

Deflection

Beams bend under load. Excessive bending (deflection) can be problematic. Span charts often include deflection limits to ensure the beam doesn’t sag too much.

Support Conditions

How the beam is supported affects its load-bearing capacity. A beam simply resting on supports performs differently than one built into a wall or one with multiple support points. Support conditions can dramatically impact how much weight a given beam can support.

Load Combinations

Real-world scenarios involve combined loads. When selecting a beam, consider the combined effects of dead, live, and snow loads. Failing to account for load combinations can lead to undersized beams and potential structural issues.

Practical Applications and Safety

Real-World Examples

Consider a deck project: You need a beam to span 16 feet, supporting the deck, furniture, people, and maybe a hot tub. The LVL span chart, combined with local building codes, helps determine the right LVL size and grade.

Consulting a Structural Engineer

Even with a good understanding of LVL span charts, consult a structural engineer, especially for complex projects. They ensure your design meets safety standards and building codes. An engineer can help analyze complex load scenarios, consider nuanced support conditions, and account for factors that might be missed with a simplified approach. Their expertise offers invaluable peace of mind.

Addressing Specific Span Questions

Can LVL Span 40 Feet?

Likely, yes. LVL’s strength makes 40-foot spans achievable, but the specific LVL beam size, grade, and support conditions are crucial. Factors like load, support type (e.g., continuous support, multiple supports), and LVL specifications heavily influence the feasibility and safety of such a span. Steel beams or Glulam could be alternatives depending on the project’s needs.

What Size LVL Beam for a 20-Foot Span?

There isn’t a single answer. The required size depends on the load, LVL grade, and support conditions. A deeper beam is generally necessary for longer spans and heavier loads. For a 20-foot span, a depth of 10-12 inches or more might be needed, but this is a rough estimate. Always refer to the manufacturer’s span chart and consult a structural engineer to ensure safety and code compliance. They can help determine the most appropriate beam size for your specific project, accounting for all the relevant variables.

- Stove Backsplash Ideas: Find Your Perfect Kitchen Style - December 24, 2025

- Stovetop Backsplash Ideas: Stylish Protection for Your Kitchen Cooking Zone - December 23, 2025

- Embossed Backsplash Tile Kitchen: Add Texture And Style - December 22, 2025