Get ready to dive into the world of highway design and construction using Civil 3D! This comprehensive guide will take you through every step of the process, from the initial planning stages to the final construction phases. Whether you’re a seasoned engineer or just starting, this guide provides the knowledge and resources you need to design safe, efficient, and environmentally sound highways.

How to Make a Highway Step-by-Step: A Civil Engineering Guide

Building a highway is a complex undertaking, much like assembling a giant puzzle. Each piece must fit perfectly to ensure a successful outcome. Let’s break down the highway construction process into manageable steps:

Step 1: Laying the Groundwork

Before any construction begins, a thorough understanding of the project’s goals and constraints is essential. This includes:

- Defining Project Goals: What are the primary objectives of this highway? What needs will it address?

- Identifying Limitations: What budget constraints, environmental regulations, or challenging terrain might influence design decisions?

- Conducting a Preliminary Environmental Assessment: Evaluating potential impacts on the surrounding ecosystems, wildlife, and communities is crucial for responsible development.

This stage involves:

- Detailed Site Surveys: Conducting comprehensive topographic surveys to understand the existing terrain, identify potential obstacles, and gather accurate data for design.

- Geotechnical Investigations: Analyzing soil composition, bearing capacity, and potential hazards helps determine the suitability of the ground for supporting the highway infrastructure.

- Preliminary Alignments and Cross-Sections: Based on the collected data, engineers sketch preliminary routes (alignments) and vertical profiles (cross-sections) of the proposed highway, considering factors like minimizing earthwork and avoiding sensitive areas.

Step 2: Designing the Blueprint

With a firm grasp of the site’s characteristics and project requirements, we move on to designing the highway’s intricate details:

- Geometric Design: This stage involves defining the highway’s horizontal and vertical layout. Engineers carefully design:

- Horizontal Alignment: Shaping the highway’s path using curves, tangents, and spiral transitions while adhering to safety standards for sight distances, vehicle speeds, and driver comfort.

- Vertical Alignment: Establishing the elevation profile of the road, including grades, curves, and superelevation to ensure safe vehicle operation and efficient drainage.

- Intersection Design: Planning safe and efficient intersections, considering factors like traffic volume, turning movements, and pedestrian safety.

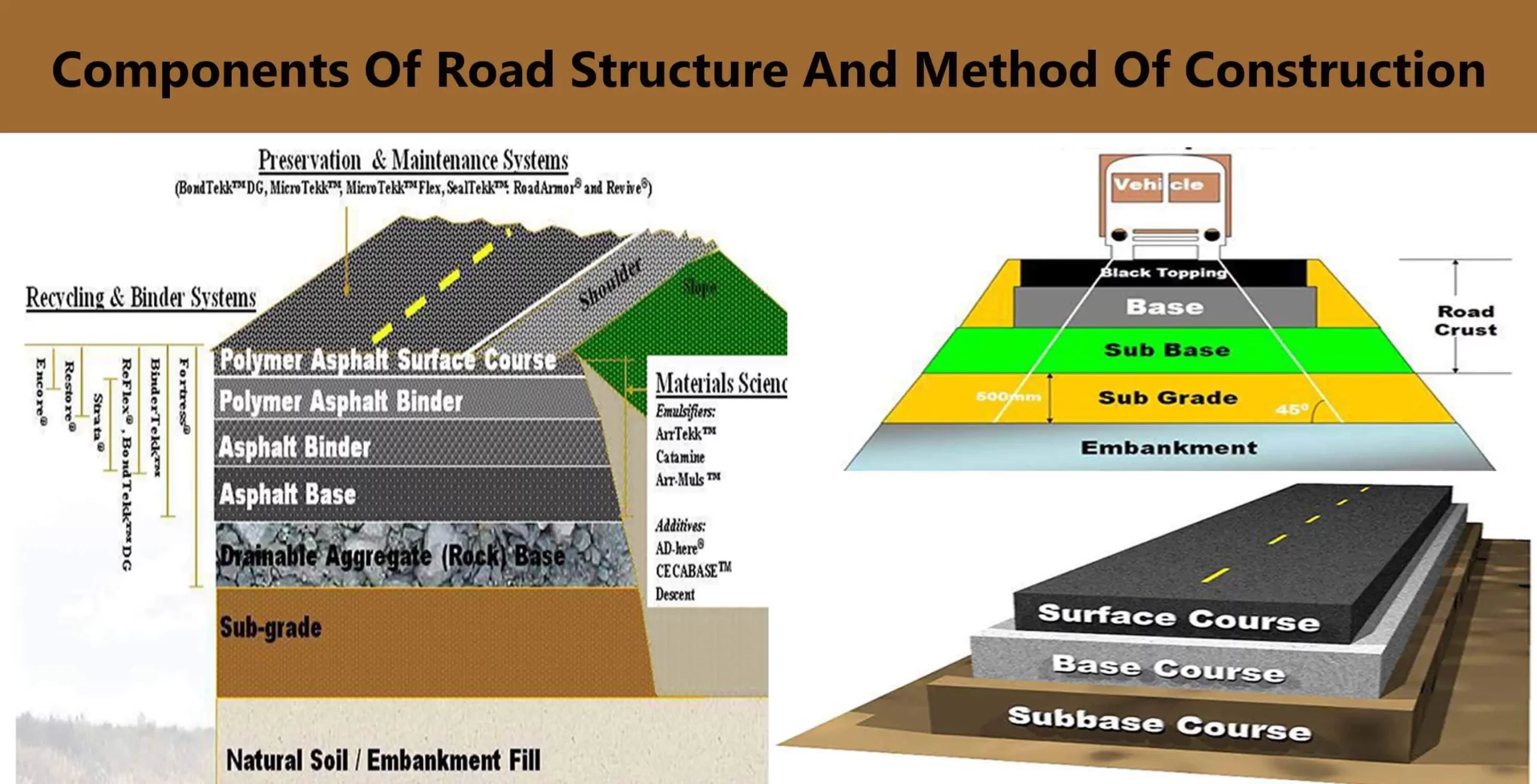

- Pavement Design: Selecting the appropriate materials for the road surface is crucial for its durability and performance:

- Traffic Analysis: Evaluating current and projected traffic volumes, vehicle types, and growth projections helps determine the structural requirements of the pavement.

- Material Selection: Engineers consider factors like cost-effectiveness, durability, skid resistance, and noise reduction when choosing materials for the base, subbase, and surface layers of the pavement.

- Drainage Design: Effective drainage is vital for highway longevity and safety:

- Hydrologic Analysis: Studying rainfall patterns and runoff characteristics helps engineers design drainage systems that can handle even extreme weather events.

- Drainage Structures: Strategically placing culverts, ditches, inlets, and retention ponds ensures efficient stormwater management, prevents erosion, and minimizes the risk of flooding.

- Traffic Control and Safety: Integrating traffic control devices is paramount for ensuring a safe and efficient flow of vehicles:

- Traffic Signals: Determining the appropriate type, phasing, and timing of traffic signals at intersections.

- Signage and Markings: Designing clear and visible signs, pavement markings, and roadway lighting to guide drivers, regulate speeds, and enhance safety.

Step 3: Picking the Right Ingredients

Building a durable and long-lasting highway requires high-quality materials that meet strict industry standards:

- Material Specifications: Engineers develop detailed specifications for each material used in the highway construction, including aggregates for the base and subbase, asphalt binder and aggregates for the pavement, and materials for drainage structures and traffic control devices.

- Quality Control: Implementing rigorous quality control measures ensures that all materials delivered to the site meet the specified standards and perform as expected.

Step 4: From Paper to Pavement – Time to Build!

With the design finalized and materials chosen, the construction phase can commence:

- Site Preparation:

- Clearing and Grubbing: Removing existing vegetation, trees, and obstacles from the construction site.

- Earthwork: Excavating or filling areas as per the design plans to achieve the desired road elevation and grade. This involves cut-and-fill operations, where soil is moved from higher elevations to lower elevations, balancing the earthwork volumes.

- Pavement Construction:

- Base and Subbase Construction: Compacting layers of granular materials to create a stable foundation for the asphalt layers.

- Asphalt Paving: Specialized equipment paves multiple layers of hot-mix asphalt, each compacted to the required density for a smooth and durable road surface.

- Final Touches:

- Shoulder Construction: Building shoulders alongside the travel lanes using compacted granular materials or paved surfaces to provide a stable edge, emergency stopping space, and lateral support for the pavement.

- Traffic Control Devices Installation: Installing traffic signals, signs, guardrails, and pavement markings according to design specifications.

- Landscaping and Erosion Control: Implementing landscaping plans and erosion control measures to enhance aesthetics, restore disturbed areas, and minimize environmental impact.

Step 5: Keeping an Eye on Things – Inspection and Monitoring

Throughout the construction process, rigorous inspection and monitoring are crucial for ensuring quality and adherence to design specifications:

- Quality Assurance/Quality Control (QA/QC): Implementing a comprehensive QA/QC program involving regular inspections of materials, processes, and workmanship helps identify and rectify any deviations from the plans and specifications.

- Testing and Verification: Conducting field tests and laboratory analyses of materials and constructed elements verifies compliance with design standards and ensures the structural integrity of the highway.

Step 6: The Long Haul – Maintenance and Rehabilitation

Maintaining a highway’s condition is essential for preserving its lifespan, ensuring safety, and maximizing its return on investment:

- Routine Maintenance: Regularly scheduled activities like crack sealing, pothole patching, drainage cleaning, vegetation control, and pavement markings refresh help prevent minor issues from escalating into major problems.

- Periodic Rehabilitation:

- Pavement Rehabilitation: Addressing more significant pavement distresses through methods like asphalt overlays, milling and resurfacing, or full-depth reconstruction.

- Structural Repairs: Repairing or rehabilitating damaged drainage structures, bridge components, or retaining walls.

Building a highway is a testament to human ingenuity and engineering excellence, requiring the collaboration of skilled professionals, careful planning, and meticulous execution.

What are the Essential Stages of Highway Construction?

Now that we have a high-level understanding of the highway construction process let’s take a closer look at the critical stages involved:

Breaking Ground and Laying the Foundation

- Clearing and Excavation: The initial step involves preparing the construction site:

- Clearing: Trees, vegetation, and structures within the proposed highway alignment are carefully removed and disposed of according to environmental regulations.

- Excavation: Topsoil is removed and stored for later use in landscaping, while the area designated for the roadway is excavated to the required depth.

- Drainage System Construction: Effective drainage is essential for preventing water from damaging the roadbed and pavement:

- Trenching: Trenches are excavated for the installation of drainage pipes, culverts, and other drainage structures.

- Pipe Installation: Drainage pipes are carefully laid in the trenches, ensuring proper slopes and connections to facilitate efficient water flow.

- Backfilling and Compaction: Trenches are backfilled with suitable materials, and each layer is compacted to prevent settling and ensure stability.

- Base Preparation: The base layer provides a stable foundation for the pavement structure:

- Subgrade Preparation: The subgrade, the soil layer beneath the base, is compacted to the required density to provide adequate support.

- Subbase and Base Layers: Layers of crushed stone, gravel, or other granular materials are placed and compacted to create a strong, stable base that distributes loads evenly and prevents pavement deformation.

Paving the Way: From Asphalt to a Smooth Finish

- Asphalt Paving: Asphalt paving is typically a multi-layered process, with each layer serving a specific purpose:

- Asphalt Production: Asphalt plants combine aggregates and liquid asphalt binder at elevated temperatures to create the hot-mix asphalt used for paving.

- Paving Operations: Specialized paving machines spread and partially compact the hot-mix asphalt, following the designed line, grade, and thickness.

- Compaction: Heavy rollers achieve the final compaction of the asphalt layers, ensuring optimal density, smoothness, and durability.

- Finishing Touches: Once the asphalt layers are in place, the finishing touches are added:

- Joint Construction: Joints are created between adjacent paving lanes to accommodate thermal expansion and contraction of the asphalt, preventing cracking.

- Shoulder Construction: Shoulders are built alongside the travel lanes, providing lateral support for the pavement, emergency stopping space, and a visual delineation of the roadway.

How Can I Design a Highway in Civil 3D Step-by-Step?

Civil 3D is a powerful software application widely used in the civil engineering industry for designing and modeling infrastructure projects, including highways. Here’s a step-by-step guide to designing a highway in Civil 3D:

Step 1: Laying the Groundwork with Your Base Map

- Create a New Drawing: Start a new Civil 3D drawing and choose an appropriate template that aligns with your project units and settings.

- Import Existing Data: Import relevant data, such as:

- Aerial Imagery: Provides a visual context of the project area.

- GIS Data: Integrate existing roads, boundaries, utilities, and other infrastructure data.

- Survey Data: Incorporate points, lines, and surfaces from land surveys to establish accurate ground control.

Step 2: Charting the Course with Alignments

- Create Alignments: Alignments define the horizontal and vertical geometry of your highway.

- Horizontal Alignments: Utilize Civil 3D’s alignment creation tools, such as lines, arcs, and spirals, to draw the proposed centerline of your highway. Specify design standards for minimum radii, superelevation, and sight distances, ensuring compliance with safety regulations.

- Vertical Alignments: Create profiles along the horizontal alignment to define the elevation changes, including grades, vertical curves, and superelevation transitions.

Step 3: Keeping it Dry: Incorporating Drainage

- Design Drainage Networks:

- Define Catchment Areas: Divide the project site into smaller catchment areas based on topography to analyze runoff patterns and calculate peak flow rates.

- Place Drainage Structures: Strategically place inlets, manholes, culverts, and other drainage structures to effectively collect, convey, and discharge stormwater runoff.

Step 4: Slicing and Dicing with Cross-Sections

- Create Assemblies: Assemblies are predefined templates that define the typical cross-section elements of your highway, such as travel lanes, shoulders, curbs, ditches, and slopes.

- Generate Cross-Sections: Once you’ve created assemblies, use Civil 3D’s tools to generate cross-sections at regular intervals along the alignment, visualizing the roadway’s shape and dimensions.

Step 5: Modeling Mother Earth: Terrain Time

- Create a Surface: Use Civil 3D’s surface creation tools to generate a 3D representation of the existing ground. This digital terrain model is crucial for earthwork calculations and visualization.

- Edit the Surface: Modify the surface to reflect proposed grading, such as cut-and-fill areas, to represent how your highway design will reshape the existing terrain.

Step 6: Earthwork Analysis: The Balancing Act

- Calculate Earthwork Volumes: Civil 3D can calculate the volumes of earth to be excavated (cut) and filled based on the difference between the existing ground surface and the proposed design surface.

- Balance Earthwork: Optimize the design to minimize earthwork quantities by adjusting grades or alignments, reducing material transportation costs and environmental impacts.

Step 7: Building the Foundation: Pavement Structure

- Create Corridors: Corridors in Civil 3D represent the 3D model of your highway, combining the alignment, profile, and assemblies to generate a comprehensive model.

- Define Pavement Layers: Within the corridor model, define the different layers of your pavement structure (subbase, base, asphalt layers), specifying their thicknesses and materials.

Step 8: Guiding the Flow: Traffic Control Elements

- Place Traffic Control Devices: Utilize Civil 3D’s extensive library of traffic control devices to place signs, signals, pavement markings, and other elements according to design standards and local regulations.

- Model Vehicle Swept Paths: Simulate vehicle movements to ensure adequate clearance and visibility for safe turning maneuvers and lane changes.

Step 9: Making it Real: Construction Documents

- Generate Plans, Profiles, and Cross-Sections: Civil 3D automates the process of generating construction drawings, including plan views, profiles (side views), and cross-sections at regular intervals, providing contractors with the necessary information for construction.

- Create 3D Visualizations: Generate realistic 3D visualizations and renderings of your highway design to communicate the project effectively to stakeholders, clients, and the public.

Step 10: From Paper to Pavement: Construction Supervision

- Stakeout Assistance: Civil 3D helps create files that can be used by surveyors to stake out the highway alignment, ensuring accurate construction.

- As-Built Modeling: After construction, update the Civil 3D model to reflect any as-built changes, providing an accurate record of the final product.

Pro Tips for Highway Design Success in Civil 3D

- Master Civil 3D’s Tools: Invest time in learning the software’s extensive features and tools, such as corridors, assemblies, and grading tools.

- Utilize Templates and Standards: Leverage existing templates, styles, and design standards to ensure consistency and efficiency in your work.

- Collaborate with Team Members: Use Civil 3D’s collaboration features to share data and drawings with other engineers, surveyors, and stakeholders involved in the project.

- Stay Updated: Civil 3D is continually evolving. Stay current with the latest software updates and new features to maximize your design capabilities.

By following these steps and leveraging the power of Civil 3D, you can effectively design highways that meet the highest standards of safety, efficiency, and sustainability.

What Factors Drive Highway Design Choices?

Designing a highway involves a delicate balancing act, considering a multitude of factors that influence design decisions:

1. Traffic Volume and Patterns:

- Capacity Analysis: Understanding current and projected traffic volumes is crucial for determining the number of lanes, lane widths, and shoulder dimensions required to accommodate traffic flow without causing congestion.

- Level of Service: Highways are designed to meet specific levels of service (LOS), which define the quality of traffic flow, ranging from free-flow conditions (LOS A) to heavily congested conditions (LOS F).

- Peak Hour Demand: Designers pay close attention to peak hour traffic volumes, ensuring the highway can handle the highest traffic loads experienced during rush hours or special events.

2. Topography and Geological Conditions:

- Terrain Adaptation: The existing topography significantly influences highway alignment. Steep slopes might require winding roads, switchbacks, or tunnels, while flat terrain allows for straighter alignments.

- Soil Conditions: Engineers carefully analyze soil properties, such as bearing capacity, stability, and drainage characteristics, to design appropriate foundation solutions and prevent pavement failures.

- Seismic Activity: In earthquake-prone areas, highway designs incorporate seismic considerations to enhance structural integrity and minimize damage during seismic events.

3. Safety Regulations and Standards:

- Design Speed: Highways are designed for specific design speeds, influencing factors like curve radii, sight distances, and superelevation rates.

- Lane Widths and Shoulders: Adequate lane and shoulder widths are crucial for safe vehicle operation, providing sufficient space for lane changes, emergency stopping, and accommodating bicycles or pedestrians.

- Clearance Heights: Vertical clearance heights for overpasses, bridges, and tunnels must adhere to regulations to accommodate trucks and other large vehicles safely.

- Safety Features: Integrating safety features, such as guardrails, crash cushions, median barriers, rumble strips, and lighting, enhances driver awareness and mitigates the severity of accidents.

4. Environmental Concerns and Sustainability:

- Environmental Impact Assessment: Assessing potential environmental impacts, such as noise pollution, air quality, water quality, and wildlife habitat disruption, is paramount in the design process.

- Minimizing Footprint: Engineers strive to minimize the highway’s footprint by optimizing alignments, minimizing earthwork volumes, and preserving existing vegetation.

- Stormwater Management: Sustainable drainage systems mimic natural processes, using techniques like bio-swales, permeable pavements, and retention ponds to filter pollutants, reduce runoff volumes, and promote groundwater recharge.

- Wildlife Crossings: In areas where wildlife habitats intersect highways, incorporating wildlife crossings, such as overpasses or underpasses, allows animals to safely cross the road, reducing wildlife-vehicle collisions.

- Noise Mitigation: Designing noise barriers or berms, using quieter pavement surfaces, and incorporating landscaping can help mitigate noise pollution for nearby communities.

5. Economic Considerations and Cost-Effectiveness:

- Life-Cycle Cost Analysis: Highway design decisions consider not only initial construction costs but also long-term maintenance, rehabilitation, and operational expenses, aiming for cost-effective solutions over the project’s lifespan.

- Value Engineering: Exploring alternative design options, materials, or construction methods can identify opportunities to reduce costs without compromising quality or safety.

- Funding Constraints: Available funding often influences the scope and scale of highway projects, requiring engineers to prioritize essential elements and find innovative solutions within budget limitations.

6. Community and Stakeholder Input:

- Public Involvement: Engaging the public and local communities throughout the design process is crucial for gathering feedback, addressing concerns, and building consensus.

- Stakeholder Collaboration: Collaboration among various stakeholders, including government agencies, transportation authorities, environmental groups, and local businesses, ensures that the highway design considers diverse perspectives and addresses community needs.

Highway design is an intricate dance between engineering principles, safety regulations, environmental stewardship, economic constraints, and community expectations. By carefully considering these factors, engineers can create highways that not only transport people and goods efficiently but also enhance quality of life, protect the environment, and foster sustainable development.

How to Make a Highway Step-by-Step in Civil 3D: Video Walkthroughs for Beginners and Experts

Key Lines:

- Master Highway Design in Civil 3D: Step-by-Step Video Tutorials for Beginners and Experts: This series provides comprehensive video walkthroughs covering all aspects of highway design in Civil 3D, from basic to advanced concepts, suitable for both those new to the software and seasoned professionals seeking to enhance their skills.

- Unlocking Roadway Design with Civil 3D: A Detailed Journey from Start to End: This video course takes you on a deep dive into roadway design principles and techniques using Civil 3D. Through real-world examples and case studies, learners gain practical insights into designing complex highway projects.

- Empowering Civil Engineers: Essential Knowledge and Resources for Advanced Highway Design: Geared towards experienced civil engineers, this resource hub offers advanced tutorials, webinars, and downloadable resources focused on cutting-edge design methodologies, industry best practices, and emerging trends in highway design.

Unique Insights:

- Hands-On Learning: Incorporate interactive exercises or quizzes within the videos to reinforce learning and provide practical experience.

- Case Studies and Best Practices: Showcase real-world highway project case studies, highlighting successful design strategies, overcoming challenges, and incorporating innovative solutions.

- Future Trends in Highway Design: Dedicate videos to exploring emerging technologies and trends impacting highway design, such as autonomous vehicles, connected infrastructure, sustainable materials, and smart city initiatives.

By providing a blend of theoretical knowledge, practical skills, and insights into real-world applications, these video resources empower civil engineers and students to confidently tackle highway design challenges and contribute to a more connected and sustainable future.

If you are wondering about the hoarding meaning in construction, this article will provide you with a clear understanding of the term and how it applies to construction projects. Additionally, if you are curious about the process involves in construction of asphalt concrete road, this article will provide you with a step-by-step guide on how this is done.

- Tile Backsplash With White Cabinets: A Kitchen Design Guide - November 25, 2025

- Best Backsplash For White Cabinets: Ideas To Transform Your Kitchen - November 24, 2025

- Modern White Kitchen Backsplash: A Guide to Stylish Kitchen Designs - November 23, 2025