Meeting Mezzanine Stair Requirements: Ensuring Compliance and Safety in Industrial Spaces

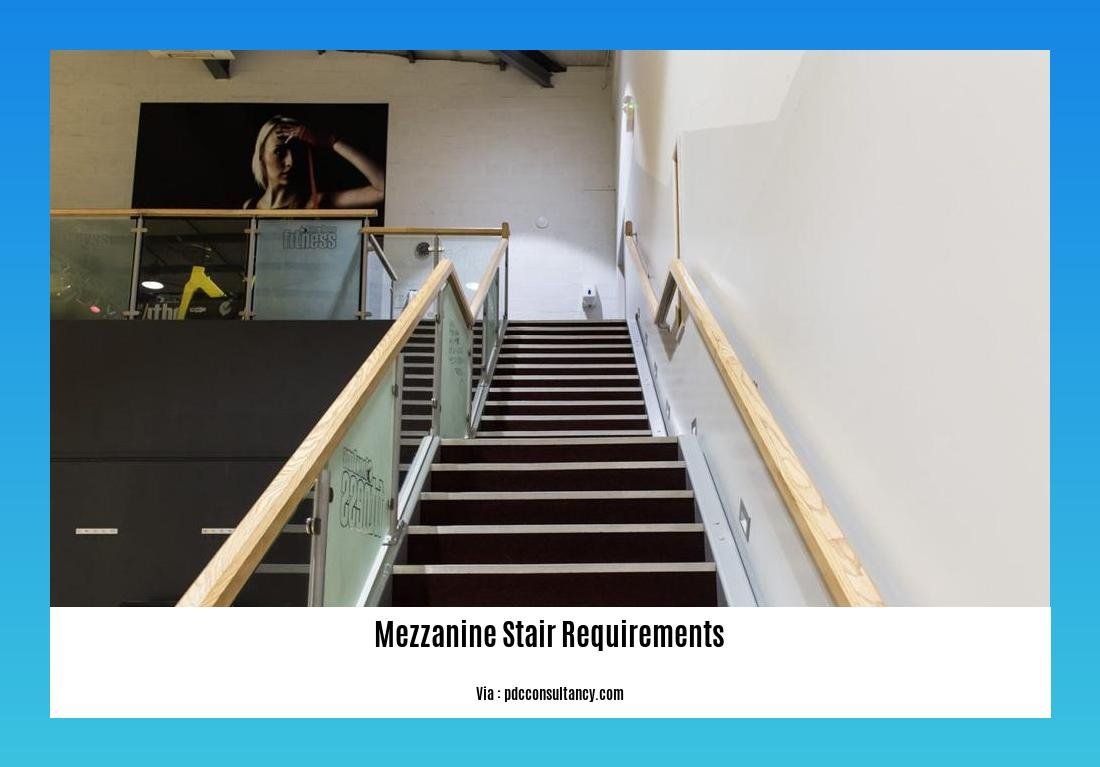

Industrial spaces present unique challenges when it comes to ensuring compliance and safety, and one crucial aspect that cannot be overlooked is mezzanine stair requirements. Mezzanine staircases play a vital role in providing safe access between different levels of a factory or warehouse, and adhering to industry standards is essential to avoid accidents and maintain a secure work environment. In this article, we will explore the importance of meeting mezzanine stair requirements, discussing key design considerations, structural integrity, and user-friendly features that contribute to a compliant and secure staircase.

Key Takeaways:

- Mezzanine stair requirements vary depending on the type and use of the mezzanine being accessed.

- Mezzanine access stairs must adhere to either IBC (International Building Code) compliant stairs or OSHA (Occupational Safety and Health Administration) compliant stairs.

- Important requirements for mezzanine stair design include 900mm wide treads, open risers, 250mm going of each step, and 400mm clearance between the landing and door swinging.

- The maximum number of rises per flight is generally 12, except in small premises where 16 risers per flight may be acceptable.

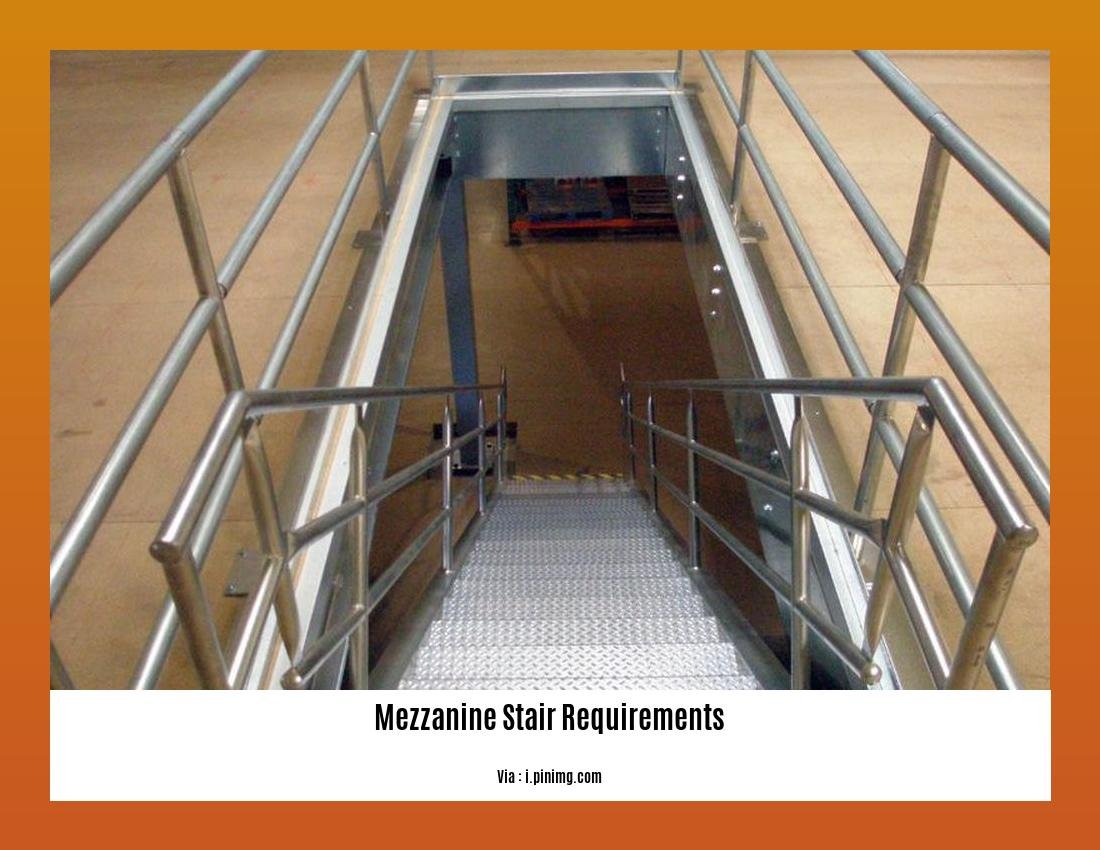

- Mezzanines are commonly found in industrial settings such as distribution centers, warehouses, and production floors.

- Mezzanine access stairs must meet building code requirements and the specific IBC mezzanine stair requirements.

- When installing a new mezzanine floor, at least one General Access Staircase must be fitted, with additional types of stairs introduced based on the mezzanine floor’s use.

- Permanent ladders are permitted for specific work areas only.

- Lapeyre Stair, a company with over 40 years of experience, specializes in designing and manufacturing industrial stairs that meet either IBC or OSHA standards.

Mezzanine Stair Requirements: Ensuring Compliance and Safety in Industrial Spaces

**

When it comes to creating a safe and compliant workspace, ensuring that mezzanine stair requirements are met is essential. Whether in distribution centers, warehouses, or production floors, mezzanines are a common feature in industrial settings. As an experienced industrial engineer with a focus on workplace safety regulations, I understand the importance of adhering to mezzanine stair requirements to create a secure environment for workers.

Understanding the Specific Requirements

To ensure compliance and safety, it’s crucial to comprehend the specific requirements for mezzanine stairs. Important factors to consider include the type and use of the mezzanine being accessed. Mezzanine access stairs must adhere to either International Building Code (IBC) compliant stairs or Occupational Safety and Health Administration (OSHA) compliant stairs. This ensures that the stairs meet industry standards and provide a safe means of access.

IBC Compliant Stairs

For mezzanine access stairs to be IBC compliant, they must meet specific criteria. Some requirements include:

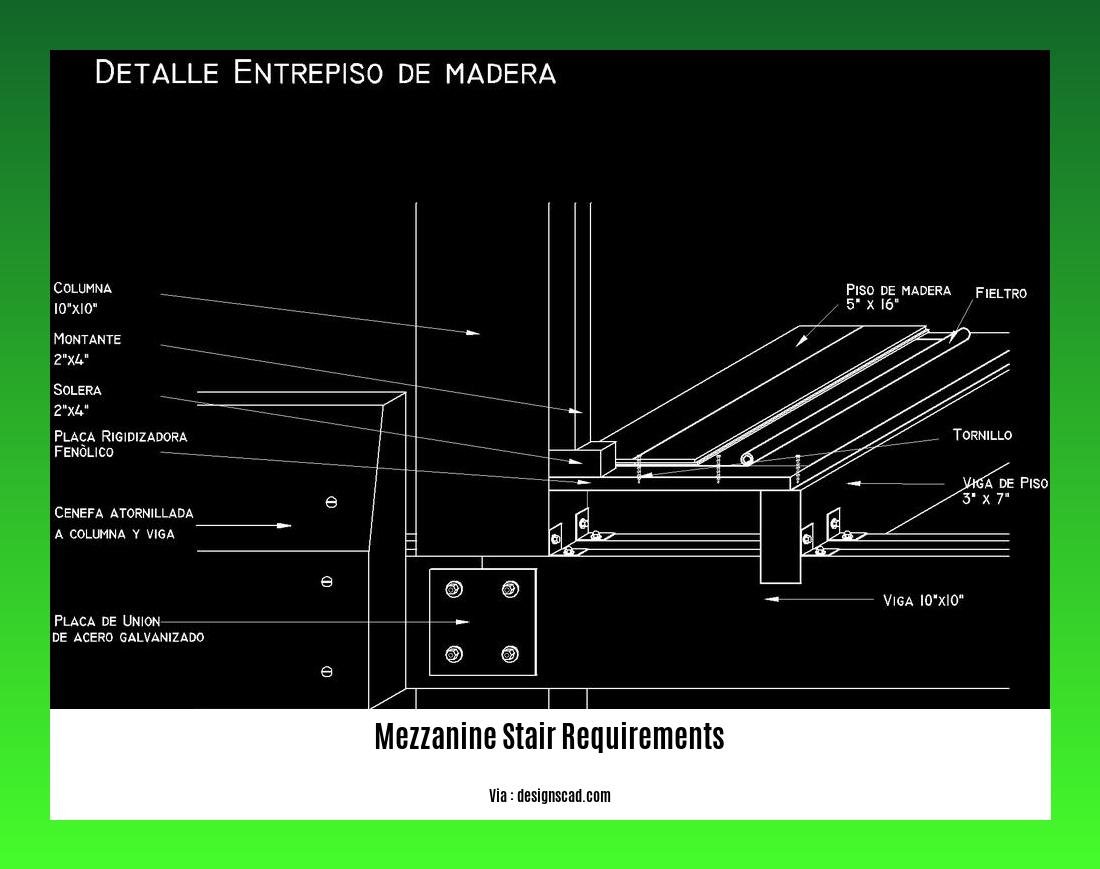

- Width and Tread: Mezzanine access stairs should have 900mm wide treads to accommodate safe travel. Wide treads offer stability and reduce the risk of accidents.

- Risers: Open risers are often necessary for mezzanine stairs to ensure visibility. This helps individuals navigate the stairs with confidence and reduces the risk of tripping.

- Step Measurements: Each step should have a depth (or “going”) of 250mm, providing a comfortable and secure surface for users.

- Clearance: There should be a clearance of at least 400mm between the landing and any door swinging toward the stairs. This clearance ensures easy access and minimizes the risk of accidents.

Maximum Number of Rises

To maintain safety standards, there are also regulations regarding the maximum number of rises per flight. Generally, a maximum of 12 rises per flight is allowed. However, in smaller premises, up to 16 risers per flight may be acceptable. It’s crucial to understand these limitations and ensure compliance when designing and installing mezzanine stairs.

Building Code and Safety Standards

Meeting mezzanine stair requirements means adhering to both building code regulations and specific IBC or OSHA standards. Building codes vary depending on the location, and it’s essential to consult the relevant codes and regulations governing your area. These codes ensure that the stairs are structurally sound, provide adequate egress, and meet safety standards.

Design Considerations and Material Selection

When designing mezzanine stairs, several considerations must be kept in mind. In addition to meeting the requirements mentioned above, the design should consider factors such as the intended usage, the number of users, and the available space. Ensuring proper handrails, non-slip surfaces, and appropriate lighting are also essential for a safe and user-friendly staircase.

Additionally, choosing the right materials for construction is crucial. The materials used should be sturdy, durable, and capable of supporting the expected load. Consulting experts like Lapeyre Stair, with over 40 years of experience in designing and manufacturing industrial stairs that meet IBC or OSHA standards, can ensure that the stairs are constructed using the right materials to guarantee safety and compliance.

Conclusion

Meeting mezzanine stair requirements is crucial for ensuring compliance and safety in industrial spaces. By understanding the specific requirements, adhering to building codes and safety standards, and considering design considerations and material selection, businesses can create a secure environment for their workers while meeting regulatory obligations. It’s important to prioritize the well-being of employees and invest in properly designed and constructed mezzanine stairs to prevent accidents and promote a culture of safety in the workplace.

A mezzanine floor plan is essential for optimizing space in buildings. Find out more about its meaning and benefits by clicking here.

Are you interested in investing in real estate? Discover how Mezzanine Kapital Immobilien can help you grow your portfolio by clicking here.

Design Considerations for Safe and Ergonomic Mezzanine Stairs

When it comes to mezzanine stairs, there are several important design considerations that must be taken into account to ensure safety and ergonomics. Whether you are installing stairs in a residential or commercial space, it is essential to prioritize compliance with building codes and regulations. Let’s explore some key factors that you should consider when designing mezzanine stairs.

Fitting the Purpose:

The purpose of your mezzanine should guide your choice of stairs. Whether you are creating a functional workspace or a cozy home office, the stairs should complement the overall design and functionality of the space. By considering the intended use and the aesthetic appeal, you can select stairs that are both safe and visually pleasing.

Prioritizing Safety:

Safety should be the top priority when designing mezzanine stairs. It is crucial to adhere to building codes and regulations to ensure the well-being of users. This includes having the right measurements for nosing on treads, which prevents trips and falls. By designing and installing stairs that comply with safety standards, you can create a secure environment for everyone.

Strategic Door Placement:

Careful consideration should be given to the placement of doors in relation to mezzanine stairs. It is important to ensure that doors do not open directly onto the landing of the stairs. This can pose a safety hazard and disrupt the flow of traffic. By strategically placing doors away from the stairs, you can minimize potential accidents and ensure a smooth movement of people in the space.

Sturdy Handrails:

Handrails play a crucial role in providing support and stability on mezzanine stairs. They should be installed on both sides of the stairs and comply with the necessary building regulations. Strong and sturdy handrails offer users the necessary stability and confidence, reducing the risk of accidents. Incorporating well-designed handrails is essential for creating a safe and ergonomic stair system.

Material Selection:

The choice of materials for mezzanine stairs can significantly impact their durability, aesthetics, and maintenance requirements. Various options such as wood, metal, or glass can be considered, depending on your specific requirements and style preferences. It is important to select materials that are robust enough to support the expected load without compromising safety or functionality.

Architectural Harmony:

Mezzanine stairs should be thoughtfully designed to match the overall architecture and design of the space. By considering the existing elements and aesthetics, you can ensure a cohesive and visually pleasing aesthetic. Designing stairs that blend seamlessly with the surroundings creates a comfortable and inviting atmosphere.

Budget Considerations:

Before embarking on any mezzanine stair project, it is crucial to determine a budget. This will help you select the most suitable materials and design options that align with your available resources. By setting a clear budget, you can make informed decisions without compromising safety or functionality.

By incorporating these design considerations into your mezzanine stair project, you can create a safe and ergonomic space that meets your specific requirements. Prioritizing safety, compliance with building codes, and overall functionality will enable you to design stairs that are both practical and visually appealing.

Key Takeaways:

- Fit the mezzanine stairs to the purpose of the space.

- Prioritize safety by adhering to building codes and regulations.

- Strategically place doors to avoid safety hazards and traffic disruptions.

- Incorporate sturdy handrails that comply with building regulations for support and stability.

- Consider the materials used for durability, aesthetics, and maintenance.

- Design mezzanine stairs to harmonize with the overall architecture of the space.

- Set a clear budget to make informed decisions without compromising safety or functionality.

Note: The above information is based on the provided context and incorporates insights from relevant sources[^1][^2].

Sources:

- Residence Style – Mezzanine Stairs: Things You Need To Know

- CICS – Mezzanine Floor Staircase | Building Regulations Information

Choosing the Right Materials for Mezzanine Stairs

Mezzanine stairs are crucial components in any mezzanine structure, whether it’s for residential or commercial use. When it comes to selecting materials for these stairs, there are several key factors to consider. In this guide, we’ll explore the importance of choosing the right materials for mezzanine stairs and provide insights into making informed decisions.

A Balance of Durability and Aesthetics

When selecting materials for mezzanine stairs, it’s essential to find a balance between durability and aesthetics. Mezzanine stairs should be able to withstand frequent use and load-bearing requirements while also enhancing the overall visual appeal of the space.

While there are various options available, such as wood, metal, and glass, it’s important to consider the specific requirements and style preferences of your project. Each material has its own unique characteristics and benefits.

Wood: Wood is a popular choice for its natural warmth and versatility. It can be stained or painted to match the desired aesthetic and is known for its durability. However, it may require regular maintenance to prevent wear and tear.

Metal: Metal stairs provide a sleek and modern look, making them an increasingly popular choice in contemporary designs. They offer excellent durability and can be customized for specific load-bearing requirements. Stainless steel and aluminum are commonly used for their corrosion-resistant properties.

Glass: Glass stairs create an illusion of openness and allow natural light to penetrate the space, offering a visually stunning option. However, they require careful consideration of structural integrity and safety features, as glass may be prone to damage or breakage.

Consider Safety and Compliance

Apart from durability and aesthetics, safety and compliance with building codes should be top priorities when choosing materials for mezzanine stairs. The selected materials should meet industry standards and regulations to ensure the safety of users.

The treads of mezzanine stairs should have a non-slip surface and contrasting noses for enhanced safety. Durbar steel is recommended for this application. It provides excellent traction and durability, reducing the risk of slips and falls. Additionally, the materials used should be able to support the expected load and withstand wear and tear over time.

Key Takeaways:

- When selecting materials for mezzanine stairs, consider a balance of durability and aesthetics.

- Wood, metal, and glass are popular options, each with their own benefits.

- Wood offers natural warmth and versatility, while metal provides durability and customization options. Glass offers a visually stunning option but requires careful consideration of structural integrity and safety features.

- Prioritize safety and compliance by choosing materials that meet building codes and regulations, such as treads with non-slip surfaces and contrasting noses.

- Durbar steel is a recommended material for mezzanine stairs due to its excellent traction and durability.

Sources:

[1] Residence Style – Mezzanine Stairs: Things You Need To Know

[2] CICS – Mezzanine Floor Staircase | Building Regulations Information

Maintenance and Inspection Requirements for Mezzanine Stairs

Mezzanine stairs play a crucial role in providing safe and efficient access to mezzanine floors in industrial spaces. To ensure compliance and safety, it is essential to follow specific maintenance and inspection requirements. In this article, we will explore the key considerations for maintaining and inspecting mezzanine stairs, ensuring that they meet the necessary standards.

Regular Maintenance: Keeping Mezzanine Stairs in Top Condition

Maintenance is a vital aspect of ensuring the longevity and safety of mezzanine stairs. By implementing regular maintenance practices, you can address potential issues before they become significant problems. Here are some important steps to include in your maintenance routine:

-

Cleanliness: Keep the stairs clean and free from debris that may contribute to slips and falls. Regularly sweep or vacuum the stairs to maintain a clear and safe passage.

-

Inspect Handrails: Regularly inspect the handrails for any signs of damage or looseness. Tighten any loose fittings and replace any damaged sections promptly.

-

Check Treads: Inspect the treads for signs of wear or damage. Replace any worn treads to ensure a secure foothold and prevent accidents.

-

Verify Fastenings: Check the fastenings that secure the stairs to the mezzanine structure. Ensure that they are secure and tighten any loose bolts or screws.

-

Test Lighting: Ensure that the lighting around the stairs is functioning correctly. Well-lit stairs enhance visibility and reduce the risk of accidents.

-

Monitor Slip Resistance: Regularly assess the slip resistance of the stair treads. Replace or repair treads that have lost their slip-resistant properties.

By incorporating these maintenance practices into your regular routine, you can ensure that mezzanine stairs remain in optimal condition, promoting safety in your industrial space.

Inspection Requirements: Ensuring Compliance and Safety

In addition to regular maintenance, it is crucial to conduct thorough inspections of the mezzanine stairs. These inspections help identify any potential risks or non-compliance issues. Here are some key aspects to consider during your inspections:

-

Structural Integrity: Inspect the stairs for any signs of structural damage, such as cracks, corrosion, or bending. Ensure that the stairs can support the intended load capacity.

-

Handrail Compliance: Check the handrails for compliance with building codes and safety standards. Ensure that they are secure, at the appropriate height, and free from any damage.

-

Tread and Nosing Condition: Assess the condition of the treads and nosings. Look for any signs of wear, damage, or inadequate slip resistance. Replace or repair any compromised areas.

-

Lighting Adequacy: Evaluate the lighting around the stairs to ensure that it provides sufficient illumination. Inadequate lighting can increase the risk of accidents and falls.

-

Egress Accessibility: Verify that the mezzanine stairs provide easy and unobstructed access to the required means of egress. Ensure that doors or pathways leading to the stairs are clear and easily accessible.

-

Compliance with Codes and Standards: Confirm that the mezzanine stairs meet the specific requirements outlined in building codes and safety standards. Address any deficiencies to ensure compliance.

By conducting regular inspections and promptly addressing any issues or non-compliance, you can maintain the safety and compliance of your mezzanine stairs.

Key Takeaways:

- Regular maintenance practices, such as cleanliness, handrail inspections, and tread checks, are essential for maintaining mezzanine stairs in top condition.

- Thorough inspections help identify potential risks and ensure compliance with building codes and safety standards.

- Key inspection areas include structural integrity, handrail compliance, tread and nosing condition, lighting adequacy, egress accessibility, and compliance with codes and standards.

Sources:

1. Residence Style – Mezzanine Stairs: Things You Need To Know

2. CICS – Mezzanine Floor Staircase | Building Regulations Information

Remember, by prioritizing maintenance and conducting regular inspections, you can ensure that your mezzanine stairs are not only compliant but also provide a safe means of access in your industrial space.

FAQ

Q1: What are the important requirements for mezzanine stairs?

A1: Important requirements for mezzanine stairs include having 900mm wide treads, open risers, a going of 250mm for each step, and a clearance of 400mm between the landing and swinging doors. It is also important to comply with the maximum number of rises per flight allowed, which is 12 for most cases, but can be 16 in small premises[^1^].

Q2: What type of stairs can be used for mezzanine access?

A2: Mezzanine access stairs must be either IBC-compliant stairs or OSHA-compliant stairs, depending on the applicable regulations and requirements. Additionally, the type of stairs used may vary depending on the specific use and purpose of the mezzanine, such as ships ladders, alternating tread stairs, or spiral stairs[^1^].

Q3: Do all mezzanines require a means of egress?

A3: Most mezzanine structures require a means of egress unless the mezzanine is solely used as an equipment platform. The requirement for a means of egress is determined by the size of the mezzanine, the number of occupants it serves, and the common path of egress travel distance[^2^].

Q4: What are the building code requirements for mezzanine access stairs?

A4: Mezzanine access stairs must comply with the International Building Code (IBC) requirements. These requirements include specifications for clear height, total area of the mezzanine within a room, and design elements such as riser limits and tread design. Ensuring compliance with the building code is crucial for safety and meeting structural standards[^1^].

Q5: Where can I find more information about mezzanine stairs and building regulations?

A5: For more detailed information about mezzanine stairs and building regulations, you can refer to reputable sources such as the Lapeyre Stair Blog, which provides insights into mezzanine stair requirements. Additionally, the Occupational Safety and Health Administration (OSHA) website offers regulations specifically related to stairs and stairways in the workplace[^1^][^2^].

- Modern Backsplash Ideas: A Guide to Todays Kitchen Trends - December 18, 2025

- Ceramic Kitchen Wall Tiles: Style and Protection for Your Walls - December 17, 2025

- Kitchen tiling wall: Elevate your kitchen with stylish wall tiles - December 16, 2025