Want a fence that can withstand a gale, a deck ready for a party, or a mailbox that stands tall? It all begins with secure post anchoring. This comprehensive guide walks you through every step, from choosing the right anchor to troubleshooting wobbles, whether you’re a DIY novice or a seasoned pro. Let’s get those posts set right!

Prepping for a Rock-Solid Foundation

Concrete Prep: The Unsung Hero

Before diving into anchors, prepping the concrete is crucial. Think of it like painting – a clean canvas yields the best results. Sweep away debris, patch cracks, and ensure a smooth surface for maximum anchor grip. This sets the stage for a truly secure and lasting connection.

Anchor Selection: Choosing the Right Tool for the Job

Selecting the right anchor can feel overwhelming, but it boils down to three factors: post size, material, and the weight it’ll bear. Here’s a breakdown:

- Wedge Anchors: The heavyweights, ideal for decks, pergolas, and large fences. These anchors offer exceptional holding power for demanding projects.

- Sleeve Anchors: Versatile workhorses for medium-duty projects like fences, gates, and signs. They provide a good balance of strength and ease of installation.

- Post Base/Anchor Brackets: The simplest option for lighter loads like mailboxes and small signs. They’re surface-mounted and quick to install.

- Epoxy Anchors: The ultimate solution for maximum strength, essential for critical structures and heavy machinery. These anchors use a chemical adhesive for a rock-solid bond.

Here’s a quick reference table:

| Anchor Type | Load Capacity | Installation Difficulty | Best Use Case |

|---|---|---|---|

| Wedge Anchor | High | Easy | Decks, Pergolas |

| Sleeve Anchor | Medium-High | Easy | Fences, Railings |

| Post Base/Bracket | Low | Very Easy | Mailboxes, Signs |

| Epoxy Anchor | Very High | Medium | High-Tension Applications |

Always consult the manufacturer’s specifications for weight limits. Choosing a slightly stronger anchor than you think you need is always a good idea—better safe than sorry!

Drilling: Precision Matters

Accurate drilling is key for a secure anchor. Measure twice, drill once! Use the correct drill bit size for your chosen anchor and drill to the specified depth. A snug fit is essential; too shallow, and the anchor won’t hold; too deep, and you risk weakening the concrete. A piece of masking tape on your drill bit can help mark the correct depth.

Installing the Anchor and Securing the Post

Follow the manufacturer’s instructions precisely when installing your chosen anchor. Some require tightening, others hammering, and still others a setting tool. Once the anchor is secure, attach your post using appropriate fasteners, ensuring it’s plumb and level.

Troubleshooting and Safety

Wobbly Posts and Loose Anchors: Quick Fixes

Encountering a wobbly post? Shims can often solve the problem. A loose anchor may require a stronger anchor type, a deeper hole, or simply more tightening. If in doubt, consult an expert at your local hardware store or search online for solutions.

Safety First: Protecting Yourself

Post anchoring involves power tools and sometimes heavy materials, so safety glasses and gloves are non-negotiable. Eye protection is paramount! Enlist help for lifting heavy posts, and don’t hesitate to call a professional if needed.

Local Codes and Green Anchoring

Always check local building codes before starting your project, as regulations may exist, especially for larger structures like decks. You may even need a permit. Consider sustainable anchoring options; some methods are more eco-friendly than others. Building strong doesn’t have to mean harming the planet.

Understanding Post Anchoring and Its Applications

What is Post Anchoring?

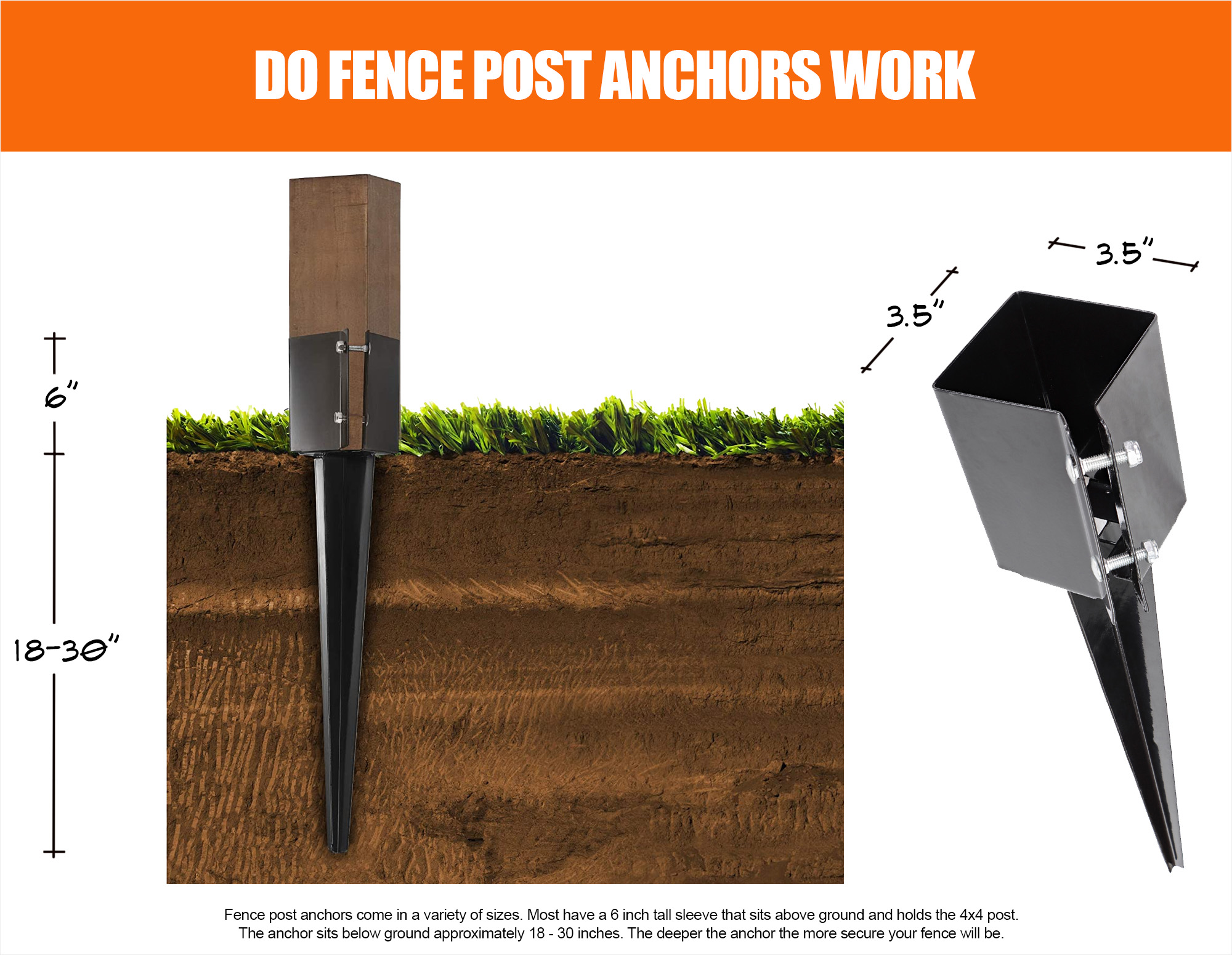

Post-anchoring is the fundamental process of attaching structures securely to existing concrete. This is how fences, decks, mailboxes, and more become firmly connected to their concrete base, ensuring stability and longevity. The post to beam connector streamlines the process of joining posts to beams. Choosing the correct anchor and proper installation are crucial for a secure and lasting result.

Matching Posts and Concrete: A World of Options

Different posts (wood, metal) and concrete types (poured, block) may require specific anchoring methods. Researching the best combination for your project is crucial, like selecting the perfect wine pairing for a meal.

Accessibility: DIY for Everyone

Post anchoring can be strenuous, but adaptive tools and techniques make these projects accessible to DIYers of all abilities.

Deep Dive into Surgical Anchors

Anchoring in Surgery: A Different Perspective

Surgical anchors are miniature devices used to securely attach soft tissues (tendons, ligaments) to bone inside the body. Much like drywall anchors, they provide a strong point of attachment.

Arthroscopic Applications: Minimally Invasive Solutions

These anchors are frequently employed in minimally invasive arthroscopic procedures, commonly used in shoulder, knee, and foot/ankle surgeries. Their precise and secure attachment helps restore stability and function.

Anchor Materials and Design: Built for the Body

Surgical anchors are crafted from materials like titanium or bioabsorbable polymers (special plastics that the body absorbs over time). Some anchors have barbs or sutures to grip the bone, while others have self-anchoring mechanisms.

Common Uses and Benefits: Restoring Joint Stability

Surgical anchors are instrumental in rotator cuff repairs, ACL reconstructions, and other procedures involving soft tissue attachment to bone. They facilitate quicker healing and improved joint function, like a strong internal knot holding tissues together.

Risks and Recovery: Navigating the Healing Process

While rare, potential risks include loosening, breakage, or infection. Ongoing research aims to improve anchor design and materials to minimize these risks. Post-surgery, a rehabilitation program is typically necessary to regain strength and mobility.

| Material | Fixation Method | Common Uses |

|---|---|---|

| Metal (Titanium) | Suture, Screw | Rotator Cuff Repair, ACL Reconstruction |

| Bioabsorbable Polymer | Barbs, Screws, Sutures | Ligament Repair, Cartilage Fixation, Meniscus Repair |

This information is for general knowledge; always consult a healthcare professional for personalized advice.

The Long Haul: Post Anchor Lifespan

How long do post anchors last? It depends on various factors, including material, installation quality, and environmental conditions.

Material Matters: Steel, Concrete, and More

- Steel Spikes: Can last up to 50 years, with galvanized or stainless steel offering superior rust resistance.

- Concrete Anchors (Brackets): The metal typically lasts for decades, but the concrete’s integrity is the limiting factor.

- Wedge Anchors: Their lifespan is tied to the concrete they’re embedded in, potentially lasting decades with proper concrete installation.

- Screw Anchors: Lifespan varies but can be extensive with proper installation and corrosion protection.

- Adhesive Anchors: Longevity depends on the adhesive quality and correct application.

Factors Affecting Lifespan: Environment and Maintenance

Coastal environments accelerate corrosion, and heavy loads stress anchors. Regular maintenance, like checking for rust or concrete cracks, extends lifespan.

Choosing the Right Anchor: A Summary

Consider post size, load requirements, and environmental factors when selecting your anchor.

| Anchor Type | Lifespan (Years) | Best For |

|---|---|---|

| Steel Spikes | Up to 50 | Fences, light-duty posts |

| Concrete Brackets | Decades+ | Decks, pergolas, heavier structures |

| Wedge Anchors | Decades+ | Heavy-duty applications |

| Screw Anchors | Varies | Versatile, many applications |

| Adhesive Anchors | Varies | High-strength applications |

These are estimates, and ongoing research may reveal different lifespans in the future. Proper anchor selection and installation are essential for a secure and long-lasting structure. Plan ahead and choose wisely for the best long-term results.

- Dora the Explorer Wipe-Off Fun: Safe & Mess-Free Activities for Little Explorers - April 18, 2025

- Does Lemongrass Repel Mosquitoes? Fact vs. Fiction + How to Use It - April 18, 2025

- Do Woodchucks Climb Trees?Fact vs. Fiction - April 18, 2025