Want that perfectly smooth, professional concrete finish? A power trowel is your answer. This comprehensive guide covers everything you need to know, from understanding what a power trowel is to choosing, using, and maintaining one. Whether you’re a DIY enthusiast or a seasoned contractor, this guide will help you achieve flawless concrete surfaces.

What is a Power Trowel?

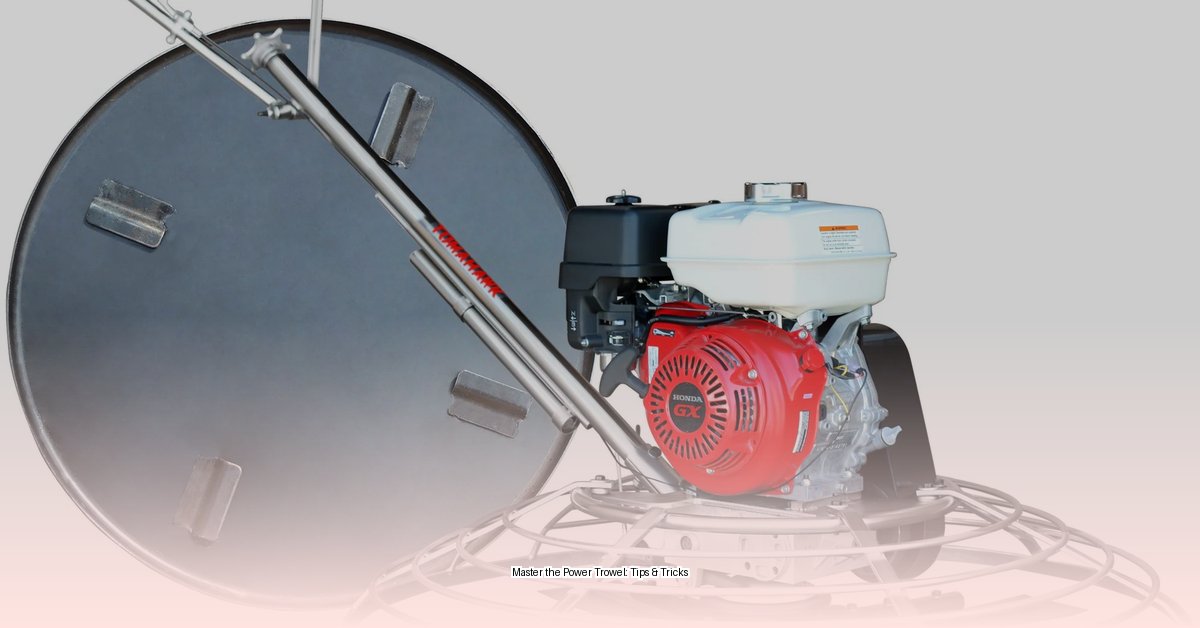

A power trowel, also known as a power float or helicopter, is a motorized tool used to smooth and finish concrete surfaces. It consists of a rotating head with adjustable blades that spin across the concrete, creating a polished, durable finish. Think of it as a giant, powered smoothing iron for concrete. Power trowels are essential for achieving professional-grade finishes, especially on large slabs where hand troweling would be impractical and time-consuming.

Types of Power Trowels: Choosing the Right Machine

Just like choosing the right tool for any job, selecting the correct power trowel is crucial. There are two primary types: walk-behind and ride-on.

Walk-Behind Power Trowels: Maneuverability Matters

Walk-behind trowels are the compact, agile option, perfect for smaller projects or areas with limited access. Imagine navigating a crowded room – a walk-behind trowel offers that same level of maneuverability. They’re ideal for projects such as patios, sidewalks, and smaller driveways. While offering excellent control and a lower price point, walk-behind trowels can be more physically demanding, especially for extended use.

Ride-On Power Trowels: Efficiency for Large Projects

For expansive concrete surfaces, a ride-on trowel offers unparalleled efficiency. Think of it as a comfortable, powerful vehicle designed for covering vast areas quickly and with minimal operator fatigue. Ride-on trowels are best suited for large-scale projects like warehouse floors, parking lots, or any surface exceeding approximately 1,000 square feet. While the initial investment is higher, the time and effort saved can be significant, especially for professionals.

| Feature | Walk-Behind | Ride-On |

|---|---|---|

| Project Size | Small to Medium | Large |

| Maneuverability | High | Lower |

| Cost | Lower | Higher |

| Operator Fatigue | Higher | Lower |

| Best For | Tight spaces, smaller slabs | Large open areas, high-volume projects |

How a Power Trowel Works: From Rough to Refined

The magic of a power trowel lies in its rotating blades. A powerful engine drives a rotating head equipped with typically three or four adjustable blades. These blades spin across the surface, smoothing and polishing the concrete. The angle of the blades, known as the pitch, is adjustable, allowing for different stages of finishing, from initial floating to final polishing. A low pitch is used for initial smoothing, while a higher pitch creates a more polished sheen.

Operating a Power Trowel: A Step-by-Step Guide

While operating a power trowel might seem daunting, with the proper technique, it becomes a manageable and rewarding process.

Pre-Operation Checklist:

- Site Preparation: Ensure the work area is clear of debris, tools, and any obstacles.

- Concrete Readiness: The concrete should be firm enough to support the machine’s weight without leaving deep impressions (approximately ⅛ inch footprint).

- Trowel Inspection: Check the machine for any damage, loose parts, or worn blades. Ensure blades are securely attached and in good condition.

- Safety Gear: Wear appropriate PPE, including eye and ear protection, a dust mask, and sturdy work boots.

Operating Instructions (General Guidelines – Consult your machine’s manual for specific instructions):

- Initial Pass (Floating): Begin with the blades at a low pitch, moving slowly across the surface. This initial pass, often done with a float pan attachment, smooths imperfections and levels the concrete.

- Subsequent Passes (Finishing): As the concrete firms up, gradually increase the blade pitch with each pass. This progressive smoothing creates a finer, more polished surface.

- Final Pass (Burnishing): For a high-gloss finish, use a high blade pitch on the final pass. This creates the ultimate sheen and completes the finishing process.

Walk-Behind Specifics:

- Practice in an open area to get a feel for the controls.

- Typically, pulling the handle up steers left, and pushing down steers right.

- Overlap each pass slightly for consistent coverage.

Ride-On Specifics:

- Familiarize yourself with the controls, as they may vary between models.

- Typically, two levers control forward/reverse movement and steering/speed.

- Operate slowly and avoid abrupt turns.

Power Trowel Blades: Choosing the Right Type

Selecting the correct blades is crucial. Floating blades are for the initial smoothing, combination blades offer versatility for both floating and finishing, and finishing blades put the final polish on the concrete.

Maintaining Your Power Trowel: Extending its Lifespan

Like any machinery, a power trowel requires regular maintenance.

- Cleaning: Remove any concrete buildup after each use. This prevents corrosion and ensures efficient operation.

- Blade Inspection & Replacement: Regularly inspect blades for wear and replace them as needed. Sharp blades are essential for optimal performance.

- Engine Maintenance: Follow the manufacturer’s recommendations for engine maintenance, including oil changes, filter replacements, and other routine tasks. This is crucial for long-term reliability.

| Maintenance Task | Frequency |

|---|---|

| Clean the trowel | After each use |

| Check/Replace Blades | Weekly (heavy use), Monthly (light use) |

| Check/Tighten Bolts | Weekly (heavy use), Monthly (light use) |

Choosing the Right Power Trowel: Factors to Consider

Selecting the right power trowel depends on several factors:

- Project Size: Walk-behind trowels are suitable for smaller projects, while ride-on trowels are designed for larger areas.

- Concrete Type: Different concrete mixes may require specific blade types or troweling techniques.

- Accessibility: Consider the work area’s accessibility. Walk-behind trowels are more maneuverable in tight spaces.

- Budget: Walk-behind trowels are generally more affordable than ride-on models.

- Operator Experience: Beginners may find walk-behind trowels easier to handle, while experienced operators might prefer the efficiency of ride-on models.

Top Power Trowel Brands: A Look at the Leaders

Several reputable brands are known for producing high-quality power trowels:

- Multiquip: Known for their durable and reliable equipment.

- MBW: Offers a range of trowels for various applications.

- Wacker Neuson: Provides high-performance trowels known for their quality.

- Allen Engineering: Specializes in concrete equipment, including a wide selection of power trowels.

- Whiteman: Produces a variety of concrete finishing equipment, including power trowels.

- Bartell: Offers innovative trowel designs and features.

Troubleshooting Common Issues

- Uneven Finish: This could be due to inconsistent speed, improper blade pitch, or variations in concrete consistency. Check your technique and ensure uniform concrete.

- Blade Wear: Dull blades are a common cause of poor finishes. Inspect and replace blades regularly.

- Engine Problems: Regular engine maintenance can prevent many problems. Consult a professional for complex issues.

The Future of Power Troweling

The field of concrete finishing is constantly evolving. Research suggests future developments may include more automated controls, laser-guided systems, and greater emphasis on environmentally friendly practices.

By understanding the different types of power trowels, proper operating techniques, and maintenance procedures, you can achieve professional-quality concrete finishes. Always prioritize safety and consult the manufacturer’s instructions for your specific model. This guide provides a strong foundation – continuous learning and practical experience will further enhance your skills.

- Stove Backsplash Ideas: Find Your Perfect Kitchen Style - December 24, 2025

- Stovetop Backsplash Ideas: Stylish Protection for Your Kitchen Cooking Zone - December 23, 2025

- Embossed Backsplash Tile Kitchen: Add Texture And Style - December 22, 2025