[[- The Importance of Prime Coat in Road Construction: Enhancing Pavement Performance and Longevity -]] Prime coat plays a vital role in road construction, serving as the bonding agent between the existing surface and the new asphalt layer. It creates a strong foundation, preventing water infiltration and ensuring the stability and durability of the pavement. This article provides insights into the significance of prime coat in road construction, highlighting its benefits and best practices for effective application. By understanding the role of prime coat, engineers and contractors can optimize road construction projects, leading to enhanced pavement performance and longevity.

Key Takeaways:

- Prime coat is a crucial layer between the base and asphalt surface of a road.

- It seals the surface, binds aggregates, enhances adhesion, and protects against moisture.

- Prime coats also harden the base, serve as a platform for equipment, and safeguard the substrate.

Prime Coat in Road Construction

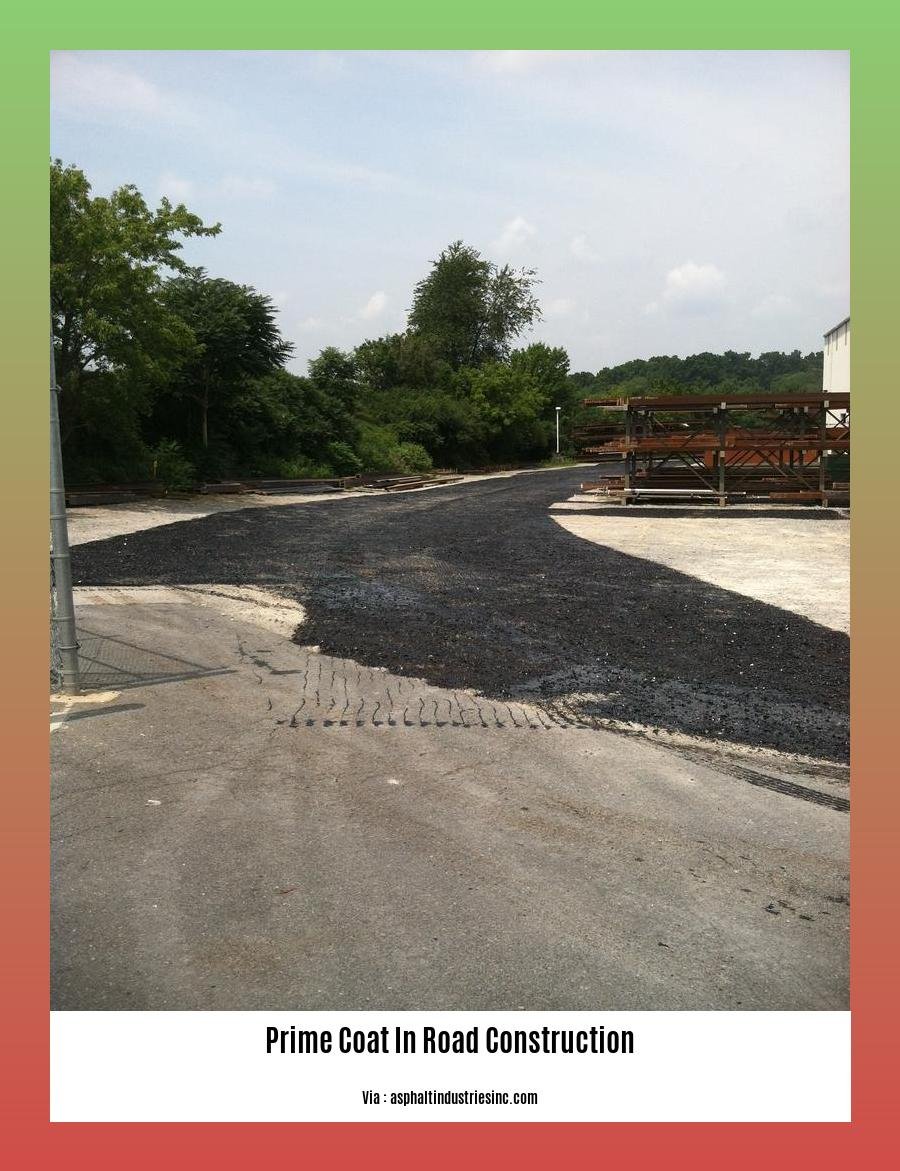

Prime coat is a key component of road construction, providing a strong foundation for pavement and enhancing its performance and longevity. It’s a thin layer of asphalt applied to the granular base, serving multiple crucial purposes:

-

Sealing the Surface: Prime coat seals the surface, preventing moisture and air from penetrating and weakening the base.

-

Binding Aggregates: It binds together loose aggregates, creating a stable and cohesive base.

-

Adhesion Promoter: Prime coat promotes adhesion between the base and the subsequent asphalt layers, ensuring a strong bond.

-

Base Protection: It protects the base from moisture damage and erosion, extending its life.

Benefits of Prime Coat

-

Improved Pavement Performance: Prime coat contributes to the overall strength and stability of the pavement structure, reducing cracking and rutting.

-

Extended Pavement Longevity: It helps protect the base from deterioration, extending the lifespan of the road.

-

Enhanced Safety: Prime coat provides a stable and even surface for vehicles, improving traction and reducing the risk of accidents.

Application Process

Applying prime coat involves several key steps:

-

Surface Preparation: The base surface is prepared by sweeping or blowing to remove any loose materials or debris.

-

Prime Coat Application: The prime coat is applied using a specialized sprayer or distributor. The application rate varies depending on the type and condition of the base.

-

Curing: After application, the prime coat is allowed to cure, typically for at least 24 hours. During this time, traffic should be avoided to allow the prime coat to fully adhere and harden.

Conclusion

Prime coat plays a vital role in road construction, enhancing pavement performance and longevity. It’s an essential component of a well-built road, providing a strong foundation that supports heavy traffic and withstands the elements. Understanding the importance and application of prime coat is crucial for ensuring the durability and safety of our roads.

If you are looking for construction materials in Ethiopia, you can check out our price list of construction materials in Ethiopia or visit our page for a price list for construction materials.

Materials and Application Techniques for Prime Coat

Hey there! Let’s dive into the nitty-gritty of Materials and Application Techniques for Prime Coat in road building.

Materials:

- Cutbacks: Liquid asphalt blended with solvents

- Prime Asphalt Emulsions: Water-mixed asphalt with emulsifying agents

- Non-Asphalt Emulsions: Binders such as rubber or polymers

Application Techniques:

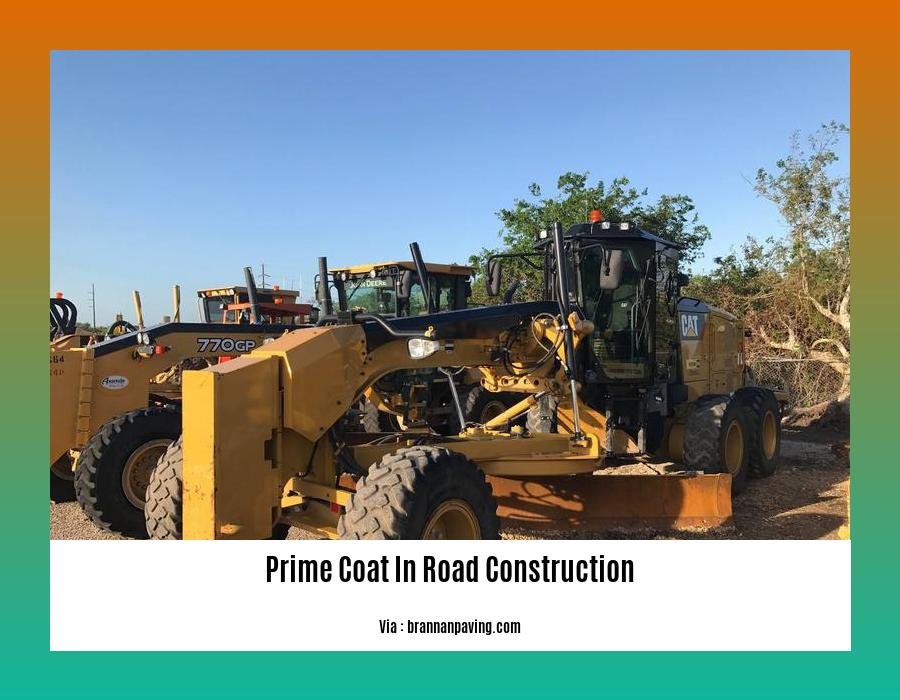

- Sprayed Prime Coat: Applied with a sprayer at a controlled rate

- Penetration Prime Coat: Poured directly onto the base and allowed to absorb

Steps to Apply Prime Coat:

- Prepare the Base: Clean and remove any loose materials.

- Choose the Prime Coat Material: Based on soil conditions and traffic requirements.

- Determine Application Rate: Calculated to achieve proper bonding and sealing.

- Apply the Prime Coat: Using either spraying or penetration methods.

- Cure the Prime Coat: Allow time for the prime coat to dry and adhere to the base.

Key Takeaways:

- Prime coat provides a crucial bond between base and asphalt layers, enhancing pavement strength.

- Selecting the right prime coat material and application technique is key for long-lasting pavement performance.

- Proper preparation and curing of prime coat ensure optimal results.

Citations:

Quality Control Measures for Prime Coat

Ensuring the quality of prime coats is paramount for successful road construction. Here are some crucial quality control measures to consider:

Surface Preparation:

– Verify that the surface is clean, dry, and free of debris to ensure proper adhesion.

Material Quality and Application Rate:

– Confirm that the prime coat material meets specifications and is applied at the correct rate (0.1-0.3 gallons per square yard).

Equipment Calibration:

– Calibrate spray equipment regularly to ensure accurate application and uniform coverage.

Weather Conditions:

– Monitor weather conditions and avoid applying prime coat in wet or freezing weather to prevent issues with curing.

Curing Time:

– Allow sufficient curing time (minimum 24 hours) before applying subsequent layers to ensure proper bonding and prevent premature damage.

Visual Inspection:

– Inspect the prime coat for any defects such as patchy coverage, bubbling, or peeling to identify and address issues promptly.

Key Takeaways:

- Proper surface preparation enhances adhesion and ensures longevity.

- Controlled application rate prevents over- or under-application, ensuring effective bonding.

- Calibrated equipment guarantees uniform coverage and consistency.

- Favorable weather conditions promote proper curing and prevent compromising the prime coat’s integrity.

- Adequate curing time allows for complete bonding and durability.

- Thorough visual inspection identifies potential problems and facilitates timely resolution.

Sources:

* Roadresource.org: https://roadresource.org/treatment_resources/prime_coat/quality_testing

* Theconstructor.org:

Case Studies and Best Practices

In the realm of road construction, prime coat stands as a crucial component, enhancing the performance and longevity of road pavements.

Case Study:

A highway project in California utilized a high-quality prime coat to bind an aggregate base to the asphalt surface. As a result, the road exhibited exceptional resistance to cracking and premature deterioration, even under heavy traffic loads.

Best Practice:

To ensure prime coat effectiveness, engineers recommend:

- Selecting the appropriate prime coat material based on soil conditions and traffic volume.

- Applying the prime coat at the correct rate and timing to avoid excessive or insufficient coverage.

- Allowing ample time for the prime coat to cure before applying subsequent layers.

Step-by-Step Process:

- Site Preparation: Clean the base surface to remove dust and debris.

- Prime Coat Application: Spray or apply the prime coat as per the manufacturer’s instructions.

- Curing: Allow the prime coat to cure for the specified time to ensure proper bonding.

- Inspection: Before proceeding with subsequent layers, inspect the prime coat for uniform coverage and adhesion.

Key Takeaways:

- Prime coat serves as a bonding agent between the road base and surface layer.

- Proper selection and application of prime coat enhances pavement durability and longevity.

- Adhering to best practices in prime coat application ensures optimal performance.

Relevant URL Sources:

- American Concrete Paving Association

- National Asphalt Pavement Association

FAQ

Q1: What is the purpose of applying a prime coat in road construction?

Q2: What factors should be considered when selecting the appropriate prime coat material?

Q3: How does the thickness of the prime coat affect its effectiveness?

Q4: What is the recommended curing time for a prime coat before applying additional pavement layers?

Q5: How does a prime coat contribute to the overall durability of a road pavement?

- Dora the Explorer Wipe-Off Fun: Safe & Mess-Free Activities for Little Explorers - April 18, 2025

- Does Lemongrass Repel Mosquitoes? Fact vs. Fiction + How to Use It - April 18, 2025

- Do Woodchucks Climb Trees?Fact vs. Fiction - April 18, 2025