Understanding PSL Beams: Strength and Versatility

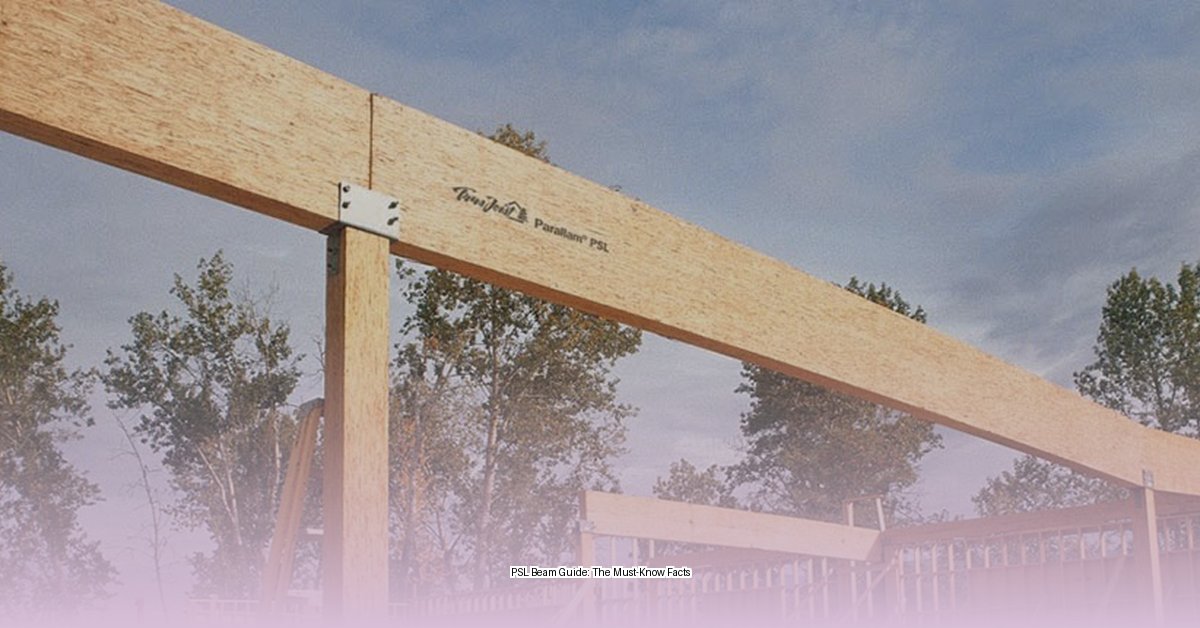

Planning a construction project? PSL (Parallel Strand Lumber) beams might be the solution for your structural needs. Whether you’re a homeowner tackling a DIY project or a contractor managing a large-scale build, understanding PSL’s benefits can be a game-changer. This guide provides a comprehensive overview of PSL beams, from their composition and uses to installation and maintenance.

What is PSL? Deconstructing the Super Lumber

Imagine thin wood strands, coated in adhesive, and pressed together under immense pressure. That’s PSL – an engineered wood product designed for superior strength and stability. This manufacturing process creates a beam that’s more consistent and predictable than traditional lumber, minimizing issues like warping, twisting, and shrinking.

Why Choose PSL? Advantages and Benefits

PSL offers a range of advantages that make it an attractive option for various construction projects:

- Exceptional Strength and Stiffness: Supports longer spans with fewer support columns.

- Dimensional Stability: Resists warping, twisting, and shrinking due to moisture changes.

- Consistent Quality: Predictable performance simplifies design and construction.

- Workability: Can be cut and shaped with standard woodworking tools (sharp blades recommended).

- Treatable: Can be treated for enhanced fire, insect, and decay resistance.

- Sustainable: Often manufactured from fast-growing, renewable wood.

- Long-Term Cost Savings: While the initial cost might be higher, durability and minimal maintenance can lead to long-term savings.

PSL Beams in Action: Residential and Commercial Uses

PSL beams play a crucial role in a variety of construction projects, both big and small:

Residential:

- Headers: Support walls above windows and doors, preventing sagging and cracks.

- Beams and Floor Joists: Enable open-concept designs by spanning longer distances without intermediary supports.

- Posts and Columns: Provide sturdy vertical support in post-and-beam construction.

- Rim Boards: Create a solid foundation around the perimeter of floors.

Commercial:

- Long-Span Beams and Columns: Essential for creating large, open spaces in warehouses, malls, and office buildings.

- I-Joists: Used as a key component in floor and roof systems, contributing to their strength and stiffness.

Sizing Up Your Needs: Dimensions and Specifications

PSL beams come in various sizes and lengths to fit diverse project requirements. Consult manufacturer specifications or work with a structural engineer to select the right size for your specific load and span needs.

(Include a table of common PSL beam sizes and their typical applications, referencing manufacturer specifications. Example below – replace with actual manufacturer data):

| Nominal Size (inches) | Typical Lengths (feet) | Potential Applications |

|---|---|---|

| 3 ½ x 11 ⅞ | Up to 60 | Residential headers, beams, smaller spans |

| 5 ¼ x 15 | Up to 72 | Longer residential spans, lighter commercial applications |

| 7 ¼ x 18 | Up to 60 | Larger openings, heavier commercial applications, long spans |

Note: This table provides general examples. Always consult manufacturers’ specifications for comprehensive size and load capacity information.

PSL vs. the Competition: LVL, Glulam, and LSL

How does PSL compare to other engineered wood products? Each has its own strengths and weaknesses:

| Feature | PSL | LVL | Glulam | LSL |

|---|---|---|---|---|

| Strength | Highest | High | High | Moderate to High |

| Consistency | Excellent | Good | Fair | Good |

| Cost | Higher | Moderate | Moderate to High | Moderate |

| Applications | Wide Range | Primarily beams | Beams & Arches | General Framing |

While PSL often exhibits greater bending strength and consistency, it may have a higher initial cost. The optimal choice depends on your project’s specific requirements and budget.

Installing PSL Beams: A Step-by-Step Guide

Proper installation is paramount for ensuring the structural integrity and safety of your project. While PSL is generally DIY-friendly, consulting a professional is recommended, especially for complex projects. Always follow manufacturer guidelines and local building codes:

- Planning: Verify that the underlying structure can support the PSL beams.

- Measuring: Double-check all measurements before making any cuts.

- Cutting: Use sharp blades and appropriate safety gear.

- Fastening: Use approved connectors and fasteners, following manufacturer recommendations.

- Inspection: Thoroughly inspect installed beams for proper alignment and secure connections.

Cost and Sustainability: The Long View

While PSL might have a higher upfront cost than traditional lumber, its longevity and low maintenance requirements often result in long-term savings. It’s a durable investment that pays off over time. Moreover, PSL’s use of renewable wood resources aligns with sustainable building practices. Ongoing research continues to explore and improve the environmental impact of PSL production, including the adhesives used.

Caring for Your PSL: Maintenance Tips

PSL beams require minimal maintenance. However, applying protective coatings can extend their lifespan, especially in exterior applications or areas with high moisture. Regular inspections are also recommended to identify and address any potential issues early on. Ongoing research explores new protective coatings that may further enhance the durability of PSL beams in harsh environments.

Finding Your PSL Supplier: Where to Buy

PSL beams are readily available at most lumberyards and building supply stores. You can also use online dealer locators provided by manufacturers like Weyerhaeuser (Parallam® PSL) to find local suppliers. The APA – The Engineered Wood Association (https://www.apawood.org/) offers additional resources and technical information.

- Grass Forever in Livermore: Your Guide to Artificial Turf - April 22, 2025

- German Roaches vs. American Roaches: Key Differences and Control - April 22, 2025

- 150+ Flowers That Start With S: A Comprehensive Guide - April 22, 2025