Is your floor feeling drafty or are your energy bills sky-high? The culprit might be hiding in plain sight: your rim joist. This unassuming part of your home’s framing plays a vital role in structural integrity, insulation, and overall comfort. In this comprehensive guide, we’ll cover everything you need to know about rim joists, from understanding their purpose to installing, insulating, and repairing them. Whether you’re a seasoned DIYer or just starting out, this guide will equip you with the knowledge you need to tackle any rim joist project.

Understanding the Rim Joist

This section dives into the fundamentals of the rim joist – what it is, what it does, and why it matters. Think of it as your Rim Joist 101.

What is a Rim Joist?

The rim joist is a horizontal beam that runs around the perimeter of your floor frame, sitting directly atop the sill plate (the piece of lumber bolted to your foundation). It connects the floor joists to the foundation walls, creating a crucial link between the bottom of your house and everything above it. It also serves as a nailing surface for your exterior sheathing, siding, and trim.

Rim Joist vs. Band Joist: Is There a Difference?

The terms “rim joist” and “band joist” are often used interchangeably, and in many cases, the distinction isn’t critical. However, some builders use “band joist” to refer to the entire perimeter assembly, including the rim joist and the end joists (the shorter joists at the ends of a floor or deck). Others might use “band joist” specifically for the exterior wall rim joist and a different term for the interior equivalent. While the terminology can be confusing, understanding the basic concept of a horizontal framing member connecting the joists to the walls is key.

| Feature | Rim Joist | Band Joist |

|---|---|---|

| Definition | The horizontal support beam on top of the sill plate | The whole assembly: rim joist + end joists + other horizontal framing |

| Location | Top of the sill plate, perimeter of the floor frame | Outer edge of the floor/deck frame |

| Function | Supports floor joists, connects them to the walls | Provides overall structural integrity, supports floor/deck loads |

Where is the Rim Joist Located, and What is it Made Of?

As mentioned, the rim joist sits on top of your sill plate, which is bolted directly to the foundation wall. It runs along the entire perimeter of your floor frame. Rim joists are typically made of the same lumber as your floor joists, commonly 2×8, 2×10, or 2×12 boards. However, engineered wood products like LVL (Laminated Veneer Lumber) or PSL (Parallel Strand Lumber) are sometimes used for increased strength and resistance to warping or twisting, particularly in areas with heavier loads.

Installing a Rim Joist: A Step-by-Step Guide

This section provides a practical guide to installing a rim joist, covering various methods and best practices.

Choosing Your Materials and Method

Select lumber that matches your floor joists in terms of dimensions and material. Ensure the lumber is straight and free of defects. The installation method you choose will likely depend on the specific construction of your floor framing.

Three Installation Methods

-

Through-Screwing: If you have a beam supporting the joists from below, you can drive 3-inch screws directly through the rim joist and into each floor joist. Pre-drilling pilot holes is recommended to prevent the wood from splitting.

-

Joist Hangers: When access to the outside face of the rim joist is limited, using joist hangers is a good option. Attach the hangers to the joists before positioning the rim joist, then secure the rim joist to the hangers with nails.

-

Parallel Rim Joist: This method is used when a rim joist needs to run parallel to the existing floor joists, like adding a crossbeam. Cut the new rim joist to fit snugly between the existing rim joists and secure it with screws.

Insulating Your Rim Joist: Keeping the Heat In

Insulating your rim joist is a crucial step in maximizing energy efficiency and preventing drafts. This section explains why it’s important and how to do it effectively.

Why Insulate the Rim Joist?

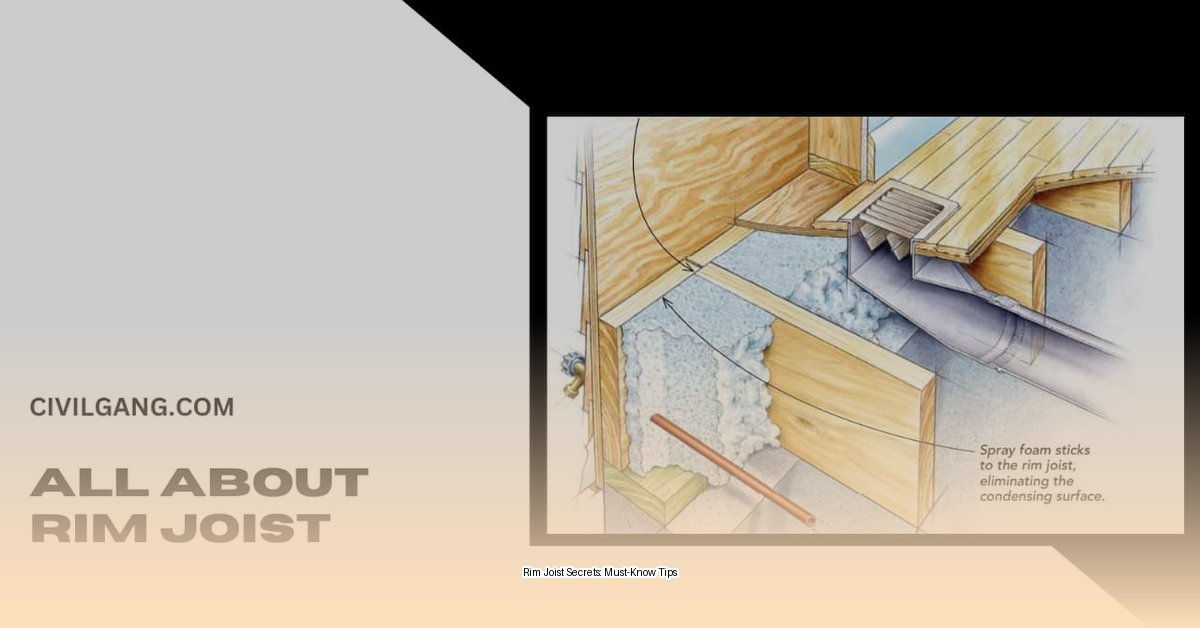

The rim joist is a major source of heat loss in many homes. Proper insulation creates a thermal barrier, reducing energy waste and improving indoor comfort. It also helps to prevent moisture problems by minimizing condensation.

Choosing the Right Insulation

Rigid foam board insulation, typically made of polystyrene or polyisocyanurate, is generally considered the most effective choice for rim joists. It’s moisture-resistant, readily available, and easy to work with. Fiberglass batts are not recommended for rim joists, as they can trap moisture, reducing their effectiveness and potentially leading to rot or mold.

Installing the Insulation

-

Prepare the Area: Clean the rim joist area and seal any gaps or cracks with caulk or expanding foam.

-

Measure and Cut (for rigid foam board): Carefully measure the spaces between your joists and cut the rigid foam board to fit snugly.

-

Install: Friction-fit the rigid foam boards into place or use construction adhesive for extra security.

-

Seal: Seal any remaining gaps around the insulation with expanding foam or caulk to create a complete air barrier.

Repairing Your Rim Joist: Addressing Common Problems

This section covers common rim joist problems and how to fix them, helping you maintain the structural integrity of your home.

Identifying and Addressing Issues

Regularly inspect your rim joist for any signs of damage, such as rot, insect infestation, or cracks.

-

Rot: Minor rot can sometimes be treated with wood hardener and epoxy. More extensive rot usually requires replacing the damaged section of the rim joist. Severely damaged rim joists probably require a professional to assess and recommend the best repair strategy.

-

Insect Damage: If you suspect insect infestation, contact a pest control professional immediately.

-

Cracks: Small cracks can often be sealed with epoxy. Larger cracks may indicate a more serious structural issue and should be evaluated by a professional.

Repairing vs. Replacing: When to Call a Pro

While minor repairs can often be tackled by DIYers, more extensive damage, especially structural issues, should be addressed by a qualified contractor. They have the expertise and tools to ensure the repair is done correctly and safely.

Building Codes and Regulations: Staying Compliant

Always check your local building codes before starting any rim joist project. Codes specify required materials, installation methods, and insulation values. Compliance not only ensures your project is safe and structurally sound but can also prevent issues with inspections and insurance.

Maintaining Your Rim Joist: Prevention is Key

Regular inspections and maintenance are crucial for preventing major rim joist problems. Check for signs of moisture, rot, or insect damage at least annually. Address any issues promptly to prevent them from becoming more serious and costly.

This guide is designed to provide a comprehensive overview of rim joists. While it covers a wide range of topics, remember that every house is unique. If you’re unsure about any aspect of your rim joist project, consulting a qualified building professional is always recommended. They can offer expert advice tailored to your specific situation and ensure the job is done correctly.

- Kitchen Backsplash For White Kitchen: Ideas To Inspire Your Renovation - November 21, 2025

- White On White Kitchen Backsplash: Is It Timeless? - November 20, 2025

- Backsplash Colors for White Cabinets: Find Your Perfect Match - November 19, 2025