Delve into the world of road construction equipment with our comprehensive guide, “Road Construction Equipment: Types, Uses, and Benefits.” This article equips you with the knowledge to navigate the diverse machinery used in the construction and maintenance of roads, from earthmovers and pavers to rollers and stabilizers. Discover the specific applications and advantages of each equipment type, empowering you to optimize your road construction projects for efficiency and quality.

Key Takeaways:

-

Equipment Used for Road Construction:

- Excavators

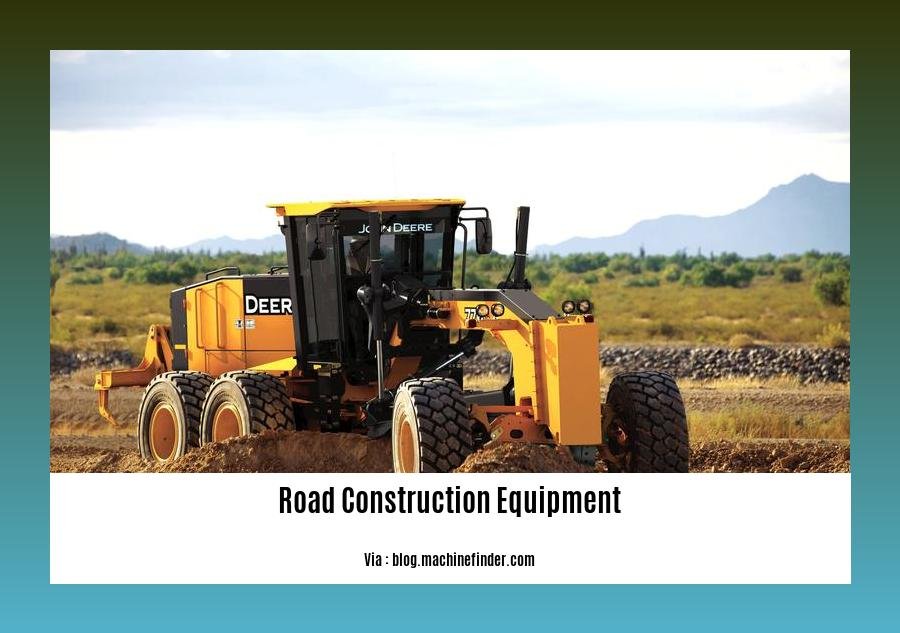

- Motor graders

- Road rollers

- Asphalt mixers

- Loaders

- Semitrailers

- Cranes

- Lifts

-

Benefits of Construction Equipment:

- Increases efficiency and productivity

- Saves labor costs

- Enhances accuracy and precision

Road Construction Equipment

Road construction equipment encompasses a diverse range of machinery specifically designed to construct and maintain roads. These machines are crucial for efficient road building, ensuring accuracy, precision, and labor savings.

Benefits of Road Construction Equipment:

- Enhanced Efficiency and Productivity: Equipment automates tasks, reducing labor requirements and expediting road construction.

- Labor Savings: Machines perform tasks that would otherwise require extensive manual labor, significantly reducing workforce needs.

- Increased Accuracy and Precision: Specialized equipment ensures precise grading, leveling, and compaction, enhancing road quality and longevity.

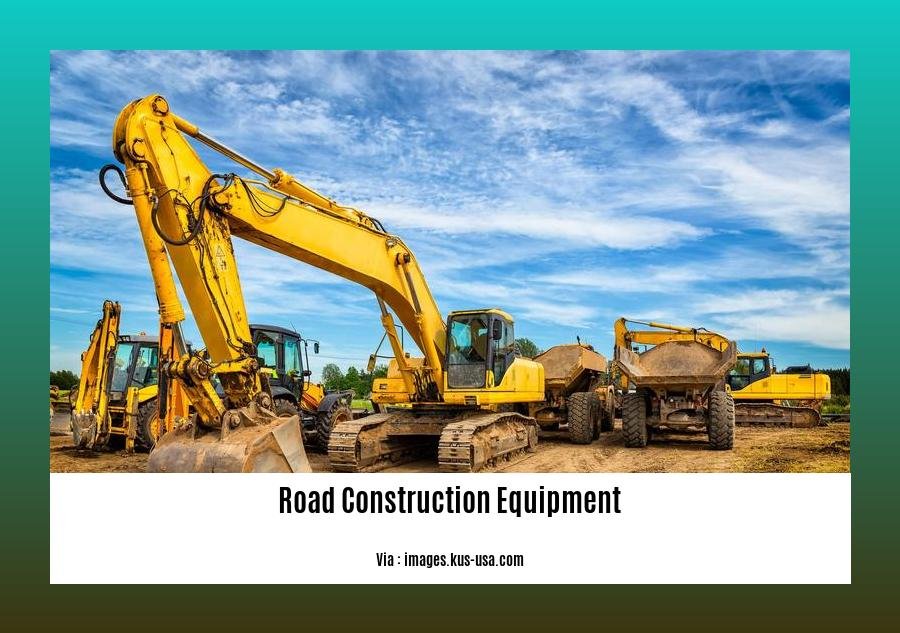

Types of Road Construction Equipment:

1. Excavators: Dig trenches and move earth for foundations, drainage, and utility installation.

2. Motor Graders: Level, shape, and maintain road surfaces, providing smooth and even surfaces.

3. Road Rollers: Compact and smooth asphalt and soil surfaces, ensuring stability and durability.

4. Asphalt Mixers: Mix asphalt materials for paving, creating a durable and wear-resistant road surface.

5. Loaders: Move and load materials such as asphalt, soil, and aggregates, facilitating efficient material handling.

6. Semitrailers: Transport heavy loads of materials and equipment to and from the construction site.

7. Cranes: Lift and position heavy objects, such as bridge beams and equipment, during construction.

8. Lifts: Provide a stable platform for workers to reach heights, enabling safe and efficient equipment maintenance and repairs.

By leveraging road construction equipment, contractors can optimize their operations, ensuring timely and cost-effective road construction while maintaining high standards of quality and safety.

-

Looking for the intricate meaning of rebate in the construction domain? rebate meaning in construction

-

Delve into the crucial details of remedial works – the cornerstone of construction excellence! remedial works in construction

-

Embark on a comprehensive exploration of residential roof construction, unlocking the secrets of a durable and visually appealing roof! residential roof construction

-

Discover the nuances of retrofit definition in construction, empowering you to make informed decisions about building enhancements! retrofit definition in construction

-

Engage in a comparative analysis of retrofit vs new construction windows, deciphering the advantages and disadvantages to guide your choice! retrofit vs new construction windows

-

Unveil the intricacies of reveal in building construction, unearthing its significance in shaping the aesthetics and functionality of structures! reveal in building construction

-

Explore the multifaceted concept of reveal in construction, gaining insights into its various applications and industry-specific nuances! reveal in construction

Benefits of Using Road Construction Equipment

Key Takeaways:

- Enhanced efficiency and productivity.

- Reduced labor costs and construction time.

- Improved work quality and infrastructure durability.

In the realm of road construction, the utilization of modern and efficient road equipment serves as a game-changer. These machines, ranging from excavators to asphalt mixers, are not mere tools but indispensable allies, amplifying project timelines, road quality, and the longevity of our infrastructure.

Firstly, road construction equipment dramatically boosts efficiency and productivity. By mechanizing repetitive and labor-intensive tasks, such as excavation, grading, and paving, these machines expedite the construction process. This not only saves time but also reduces the need for manual labor, leading to significant cost savings.

Secondly, these machines significantly reduce labor costs. Heavy-duty equipment takes on the brunt of strenuous tasks, eliminating the need for large labor forces. This not only reduces project expenses but also enhances job site safety by minimizing the risk of accidents.

Finally, road construction equipment plays a crucial role in improving work quality and infrastructure durability. Advanced machines, equipped with precise sensors and automated controls, ensure accurate grading, paving, and compaction, resulting in smoother, more durable roads. This not only enhances the driving experience but also extends the lifespan of our roadways, reducing the need for costly repairs and maintenance.

In conclusion, the adoption of efficient road construction equipment is paramount for successful road construction projects. These machines not only streamline the process but also reduce costs, improve quality, and enhance safety. By embracing the latest technological advancements in road construction equipment, we can build roads that are not only efficient and cost-effective but also safe and durable for generations to come.

Citations

- Mastering the Roads: The Rise of Efficient Road Equipment

- Role of Road Equipment in Road Construction Process

Challenges of Using Road Construction Equipment

In the realm of road construction, where precision and efficiency reign supreme, equipment plays a pivotal role. However, operating these colossal machines comes with its fair share of challenges. Here’s an exploration of the hurdles that road construction professionals navigate:

Obstacle 1: Environmental Constraints

Road construction often takes place in diverse and unpredictable weather conditions. Inclement weather, from torrential rain to blistering heat, can significantly impact equipment performance. Rain can render soil unstable, making it difficult for heavy machinery to maneuver. Extreme heat, on the other hand, can overheat equipment, leading to breakdowns and delays.

Obstacle 2: Terrain Complications

Terrain irregularities pose another challenge. Uneven ground, steep slopes, and narrow workspaces can make it difficult to operate equipment safely and effectively. Excavators may struggle to maintain stability on uneven surfaces, while cranes may have limited maneuverability in confined spaces.

Obstacle 3: Equipment Wear and Tear

The relentless nature of road construction takes its toll on equipment. Frequent use, coupled with demanding conditions, leads to increased wear and tear. This can result in breakdowns, costly repairs, and downtime, disrupting project schedules and budgets.

Obstacle 4: Operator Skill and Training

Skilled and experienced operators are crucial for the smooth operation of road construction equipment. Inexperienced operators, however, can pose a safety hazard and increase the risk of accidents. Proper training is essential to ensure operators have the knowledge and skills to handle heavy machinery safely and efficiently.

Obstacle 5: Equipment Cost and Maintenance

Road construction equipment is a significant investment. Acquiring, maintaining, and repairing this equipment can be a financial burden for contractors. Regular maintenance is crucial to extend the lifespan and performance of equipment, but it also comes with additional costs and downtime.

Key Takeaways:

- Environmental constraints (weather conditions) can affect equipment performance and safety.

- Terrain complications (uneven ground, slopes, narrow spaces) can hinder equipment maneuverability.

- Equipment wear and tear due to frequent use and demanding conditions can lead to breakdowns and downtime.

- Operator skill and training gaps can increase the risk of accidents and operational inefficiencies.

- Equipment cost and maintenance represent significant financial considerations for contractors.

Relevant Sources:

- Construction Equipment Maintenance: A Comprehensive Guide

- Managing Road Construction Equipment: Best Practices for Efficiency and Productivity

Future Trends in Road Construction Equipment

Key Takeaways:

- Autonomous vehicles: Increased road capacity and improved efficiency.

- Advanced materials and construction techniques: Enhanced road durability and reduced maintenance costs.

- Data analytics and sensors: Predictive maintenance and efficient road management.

- Sustainability and environmental considerations: Reduced ecological impact of road construction.

As technology continues to advance, the road construction industry is witnessing significant transformations. Future trends in road construction equipment hold immense potential to enhance efficiency, improve safety, and reduce environmental impact.

-

Autonomous vehicles: Self-driving construction equipment will revolutionize road construction. Narrower lanes will allow for increased road capacity, while autonomous vehicles perform tasks with greater precision and efficiency.

-

Advanced materials and construction techniques: Innovative materials and advanced construction techniques will enhance road durability and longevity. Self-healing asphalt, for instance, automatically repairs cracks, reducing maintenance costs and extending road life.

-

Data analytics and sensors: Sensors embedded in construction equipment will generate real-time data on equipment performance and road conditions. Predictive maintenance capabilities and data-driven decision-making will lead to more efficient road management.

-

Sustainability and environmental considerations: The future of road construction will prioritize sustainability. Environmentally friendly materials, such as recycled asphalt, will reduce the carbon footprint of construction projects. Advanced equipment with lower emissions will contribute to cleaner air and reduced noise pollution.

Investing in future trends in road construction equipment will drive innovation,提高 productivity, and ensure the longevity and safety of our road infrastructure. As the industry evolves, we can expect even more groundbreaking advancements that will revolutionize the way roads are built and maintained.

Citations:

– McKinsey & Company: Road work ahead: The emerging revolution in the road industry

– Mordor Intelligence: Road Construction Machinery Market – Growth, Trends, COVID-19 Impact, and Forecasts (2023 – 2028)

FAQ

Q1: What are the different types of road construction equipment?

A1: Excavators, motor graders, road rollers, asphalt mixers, loaders, semitrailers, cranes, and lifts are commonly used equipment in road construction.

Q2: What are the benefits of using road construction equipment?

A2: Road construction equipment increases efficiency, productivity, saves labor, and enhances accuracy and precision in the construction process.

Q3: What is the significance of road construction equipment in the industry?

A3: Equipment costs account for 60-70% of road construction project expenditures, emphasizing their importance in the industry.

Q4: How does advanced technology impact road construction equipment?

A4: Advanced technologies enhance productivity, safety, and cost-effectiveness by introducing autonomous vehicles, advanced materials, data analytics, and sensors in road construction equipment.

Q5: What are the emerging trends in road construction equipment?

A5: Sustainability and environmental considerations are influencing innovations in road construction equipment, focusing on reducing the ecological impact through new materials and processes.

- Dora the Explorer Wipe-Off Fun: Safe & Mess-Free Activities for Little Explorers - April 18, 2025

- Does Lemongrass Repel Mosquitoes? Fact vs. Fiction + How to Use It - April 18, 2025

- Do Woodchucks Climb Trees?Fact vs. Fiction - April 18, 2025