In the construction industry, ensuring the safety of workers is paramount. Safety nets are an essential component of this, providing a crucial barrier to prevent falls and minimizing the risk of serious injuries or fatalities. In this comprehensive guide, we will explore the importance of safety nets for construction sites, their types, applications, and best practices for their selection and deployment.

Key Takeaways:

- Safety nets are crucial for protecting against accidental falls on construction sites.

- They are the most cost-effective fall prevention system.

- Nets are made of flexible and durable high-density polyethylene (HDPE).

- Nets are required when work areas are 10 feet or higher above the ground.

- ANSI-ASSE A10.11 provides guidelines for the design, installation, and use of safety nets.

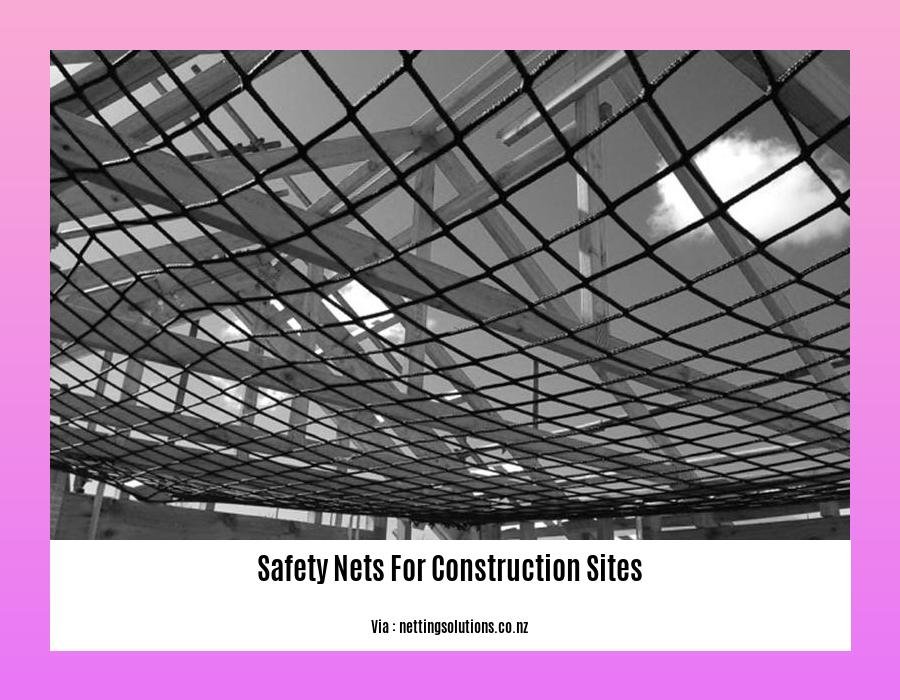

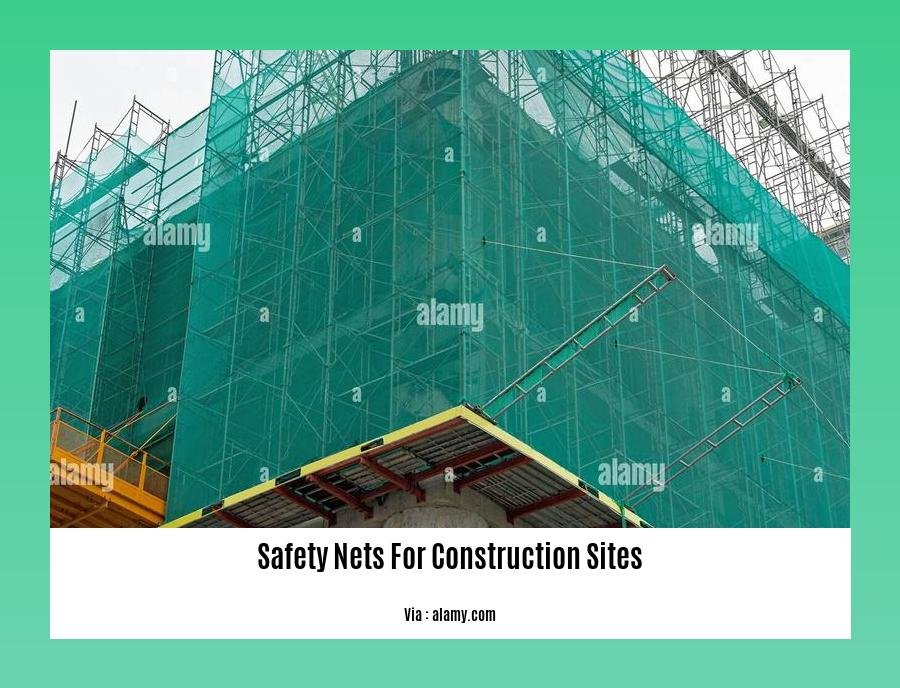

Safety Nets for Construction Sites

Safety nets are an essential piece of safety equipment for construction sites. They provide a safety net, literally, in the event of a fall.

Types of Safety Nets

There are two main types of safety nets used on construction sites:

- Horizontal safety nets are used to protect workers from falls from heights.

- Vertical safety nets are used to protect workers from falling objects.

When to Use Safety Nets

Safety nets are required on construction sites when the work area is 25 feet or higher above the ground. However, they can also be used in other situations where there is a risk of a fall, such as when working on scaffolding or ladders.

Benefits of Safety Nets

Safety nets provide a number of benefits for construction sites, including:

- They protect workers from falls.

- They are a cost-effective way to prevent accidents.

- They can improve morale and productivity.

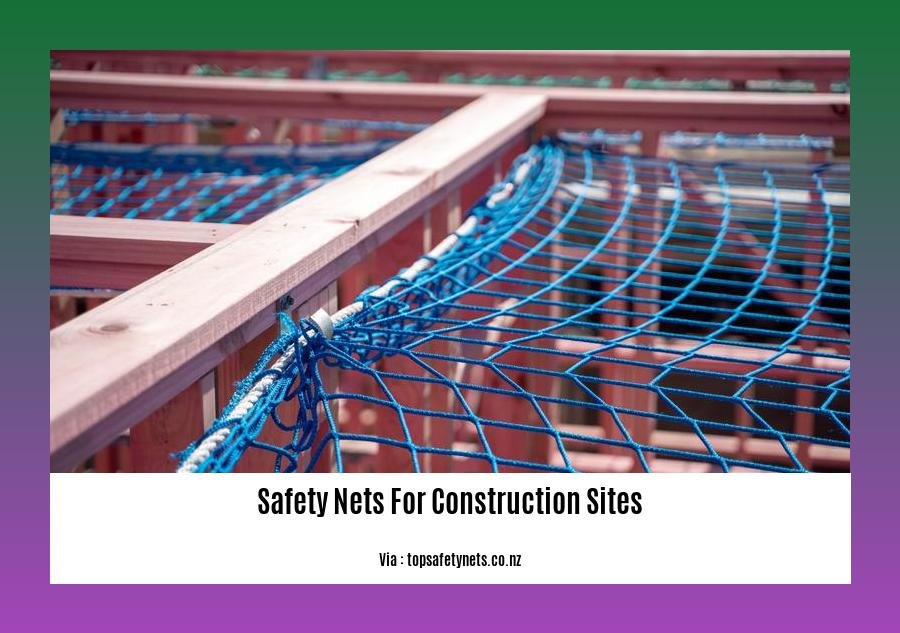

Installation and Maintenance

Safety nets must be installed and maintained according to the manufacturer’s instructions. This includes inspecting the nets regularly for damage and replacing them when necessary.

Conclusion

Safety nets are an essential piece of safety equipment for construction sites. They provide a safety net in the event of a fall, and they can help to prevent accidents and improve productivity.

If you are concerned about the well-being of construction workers, discover the most common safety issues in the construction industry.

Construction safety is of paramount importance, and safety observation examples in construction sites can provide valuable insights into potential hazards.

For those seeking a career in construction safety, explore a comprehensive safety officer construction job description to understand the roles and responsibilities involved.

Furthermore, gain a deeper understanding of the crucial safety officer duties and responsibilities in construction to ensure a safe work environment.

Benefits of using safety nets on construction sites

Safety nets are a must-have on construction sites, offering several key advantages that can significantly enhance worker safety and reduce the risk of falls. These benefits include:

-

Minimizing fall distances: Safety nets are designed to catch individuals who fall from heights, reducing the distance they fall and minimizing the risk of severe injuries.

-

Energy absorption and deflection: Safety nets are made of materials that absorb and deflect the force of a fall, further reducing the likelihood of injuries.

-

Legal compliance: In many jurisdictions, safety nets are required by law to ensure worker safety at construction sites.

-

Cost-effective accident prevention: Safety nets are a cost-effective way to prevent falls, which can lead to costly accidents and lost productivity.

-

Improved worker morale and productivity: When workers know they are protected by safety nets, they can feel more confident and productive, leading to increased efficiency on the job site.

Key Takeaways:

- Safety nets significantly reduce the risk of injuries from falls.

- Compliance with safety regulations often mandates the use of safety nets.

- Nets offer a cost-effective solution for preventing accidents and improving productivity.

Relevant URL Sources:

- Safe use of safety nets | WorkSafe

- Safety Nets at Construction Sites – ANSI Blog

Regulations and Codes for Safety Nets

Safety nets play a crucial role in preventing falls and ensuring worker safety on construction sites. To ensure their effectiveness, strict regulations and codes govern their installation, usage, and maintenance.

Key Takeaways:

- OSHA 1926.105(d) and HSE guidelines provide comprehensive regulations on safety net usage.

- Safety nets must be installed as close to the working surface as possible, with a maximum distance of 30 feet below.

- Weekly inspections are mandatory to check for damage and ensure proper functionality.

- Mesh size should not exceed 6×6 inches to prevent small objects from passing through the net.

- Nets must have a border rope with a minimum strength of 5,000 lbs to withstand potential impact forces.

Adhering to these regulations and codes is paramount to creating a safe work environment and reducing the risk of falls and serious injuries on construction sites.

Citation:

Inspection and maintenance of safety nets

Regular inspection and maintenance of safety nets are crucial to ensure the safety and effectiveness of these critical fall protection systems. Here’s a comprehensive guide to safeguard your construction sites:

Inspection frequency

Inspect safety nets weekly or more frequently in high-risk areas or after severe weather events.

Inspection checklist

Thoroughly examine safety nets for:

- Tears, holes, or snags

- Damage to mesh, ropes, and borders

- Corrosion or rust

- Loose or frayed connections

Repair and maintenance

Immediately repair or replace damaged safety nets.

- Trained personnel should perform repairs according to manufacturer’s instructions.

- Keep a maintenance log to document inspections and repairs.

Key Takeaways:

- Weekly inspections ensure safety net integrity and effectiveness.

- Repairs should be prompt and professional to maintain protection standards.

- Documentation of inspections and maintenance is essential for compliance and liability purposes.

Relevant URL Sources:

- Safety Nets and Soft Landing Systems

- Safe Use of Safety Nets

FAQ

Q1: What are the primary benefits of using safety nets at construction sites?

A1: Safety nets provide crucial protection against accidental falls, reducing the distance and impact of a potential fall, thereby mitigating the risk of severe injuries.

Q2: What is the legal status of safety nets in the construction industry?

A2: In many jurisdictions, safety nets are mandated by law to ensure worker safety and prevent injuries caused by falls from elevated work areas.

Q3: What are the critical inspection and maintenance requirements for safety nets?

A3: Weekly inspections are necessary to check for damage and ensure the integrity of the net. The mesh size should not exceed 6×6 inches, and the border rope must possess a minimum strength of 5,000 lbs.

Q4: How is the placement of safety nets determined?

A4: Safety nets should be positioned as close to the working surface as possible, with a maximum distance of 30 feet below. This strategic placement minimizes the potential fall distance and provides effective protection.

Q5: What are the advantages of using safety nets over other fall protection systems?

A5: Safety nets are considered the safest and most cost-effective fall prevention system. They offer a passive form of protection that does not require active engagement from workers, reducing the risk of human error or improper use.

- Backsplash For Cooktop: Stylish Ideas To Protect and Enhance - December 25, 2025

- Stove Backsplash Ideas: Find Your Perfect Kitchen Style - December 24, 2025

- Stovetop Backsplash Ideas: Stylish Protection for Your Kitchen Cooking Zone - December 23, 2025