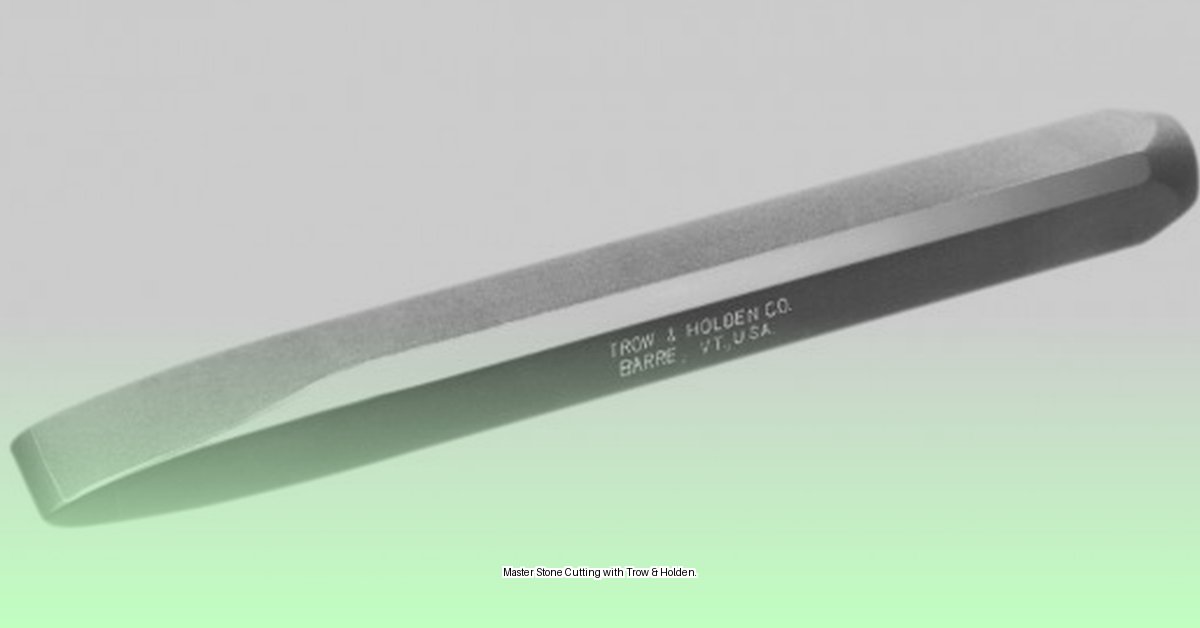

Since 1890, Trow & Holden has crafted premium stone cutting and masonry tools in Barre, Vermont. This comprehensive guide explores their rich history, diverse product line, and expert techniques, empowering you to master the art of stonework.

A Century of Craftsmanship: The Trow & Holden Story

Trow & Holden’s story began in 1861 as Stafford and Holden, crafting agricultural tools for Vermont farmers. The invention of the small air hammer in 1888 by William Holden marked a pivotal moment, shifting the company’s focus to stone-cutting tools and leading to the birth of Trow & Holden in 1890. This likely revolutionized the stone-cutting industry, enabling more intricate designs and faster work. The company’s early adoption of tungsten carbide tips further enhanced tool durability and precision, solidifying their position as innovators in the field. Still family-owned and operated, Trow & Holden continues its legacy of handcrafted excellence, with each employee undergoing a rigorous four-year apprenticeship to master the art of toolmaking. This dedication probably suggests a commitment to quality rarely seen today, as noted by some experts.

Choosing Your Tools: A Guide to the Trow & Holden Arsenal

Selecting the right tool is paramount for successful stonework. Trow & Holden offers a comprehensive range of tools tailored to specific stone types and tasks. Whether you’re shaping granite, detailing marble, or sculpting soapstone, you’ll likely find the perfect instrument within their catalog.

Hand Tools: Precision and Control

For intricate work and delicate control, Trow & Holden’s hand tools are indispensable.

- Chisels: Available in various shapes and sizes, including flat, toothed, and pointed chisels, these tools are essential for shaping, texturing, and detailing stone. Carbide-tipped chisels offer exceptional durability for working with harder stones.

- Hammers: Hand hammers provide precise control for delicate work, allowing for nuanced shaping and finishing.

- Hand Sets and Pitching Tools: These tools are invaluable for quickly removing large sections of stone, especially during the initial stages of a project.

- Tracing Tools: For intricate detailing and precise pattern transfer, tracing tools offer unparalleled accuracy.

Pneumatic Tools: Power and Efficiency

For larger projects and demanding tasks, Trow & Holden’s pneumatic tools deliver power and efficiency.

- Type B Pneumatic Hammers: The short-stroke design of Type B hammers makes them ideal for fine detail work, particularly on softer stones like limestone and sandstone. Available sizes range from ½” to 1″.

- Type D Pneumatic Hammers: With a longer stroke, Type D hammers provide the force needed for heavy-duty work and harder stones like granite and marble. Sizes range from ½” to 1 ¼”.

- Pneumatic Chisels: A wide variety of pneumatic chisels complements Trow & Holden’s hammers, enabling a range of tasks from texturing and lettering to mortar removal.

Choosing the Right Pneumatic Tool:

| Tool Type | Sub-Type | Sizes Available | Recommended Use |

|---|---|---|---|

| Pneumatic Hammer | Type B | 1/2″, 5/8″, 3/4″, 1″ | Fine detail work, softer stone |

| Pneumatic Hammer | Type D | 1/2″, 3/4″, 1″, 1 1/4″ | Heavy-duty work, harder stone, larger projects |

| Pneumatic Chisels | Various | Wide range | Specific tasks like texturing, lettering, shaping, mortar removal |

Air Compressor Recommendation: Trow & Holden suggests a minimum 3 HP air compressor for optimal performance. A more powerful compressor ensures consistent power and prevents premature wear on tools.

Specialized Tool Sets: Tailored to Your Craft

Trow & Holden offers curated tool sets designed for specific disciplines like sculpting, dry stone construction, and millstone dressing. These sets provide a convenient and cost-effective way to acquire the essential tools for your chosen craft.

Choosing the Right Chisel for the Job:

| Stone Type | Task | Recommended Chisel |

|---|---|---|

| Granite | Shaping | Carbide-Tipped Chisel |

| Marble | Detailing | Fine-Toothed Chisel |

| Limestone | Roughing Out | Medium-Toothed Chisel |

| Sandstone | Carving | Tooth Chisel |

| Soapstone | Sculpting | Fine-Toothed Chisel |

Mastering Stonework: Techniques and Best Practices

Effective stonework requires more than just the right tools; it demands skillful technique and an understanding of how tools interact with different stones. Working with delicate marble necessitates a gentler approach than tackling the robust nature of granite.

- Technique: Proper body positioning, chisel angle, and the force of each blow are crucial for achieving clean lines and precise results. There is ongoing research into the subtle tactile feedback that experienced stoneworkers perceive, suggesting that the “feel” of the stone is as important as the technique itself.

- Resources: Trow & Holden’s “Introduction to Stone Cutting Tools” video provides valuable foundational knowledge. Further mastery comes through practice, experimentation, and a deep understanding of the relationship between tool and stone.

Tool Care: Preserving Your Investment

Proper maintenance is essential for maximizing the lifespan and performance of your Trow & Holden tools. Regular cleaning prevents debris buildup, sharpening maintains cutting edges, and occasional lubrication preserves moving parts in pneumatic tools. Consult Trow & Holden’s resources for detailed maintenance guidelines.

Finding Your Tools: Connecting with Trow & Holden

Ready to equip your workshop? Trow & Holden’s website offers a wealth of information, including detailed product descriptions, specifications, and videos demonstrating tools in action. Use their dealer locator to connect with authorized retailers in your area.

By embracing the legacy of Trow & Holden, you gain access to tools and knowledge that empower you to transform your stonework vision into reality.

- How to Remove Water Stains from Fabric: A Complete Guide - April 26, 2025

- How to Get Motor Oil Out of Clothes: Proven Methods & Expert Tips - April 26, 2025

- How to Get Deodorant Out of Black Shirts: Easy Stain Removal Guide - April 26, 2025