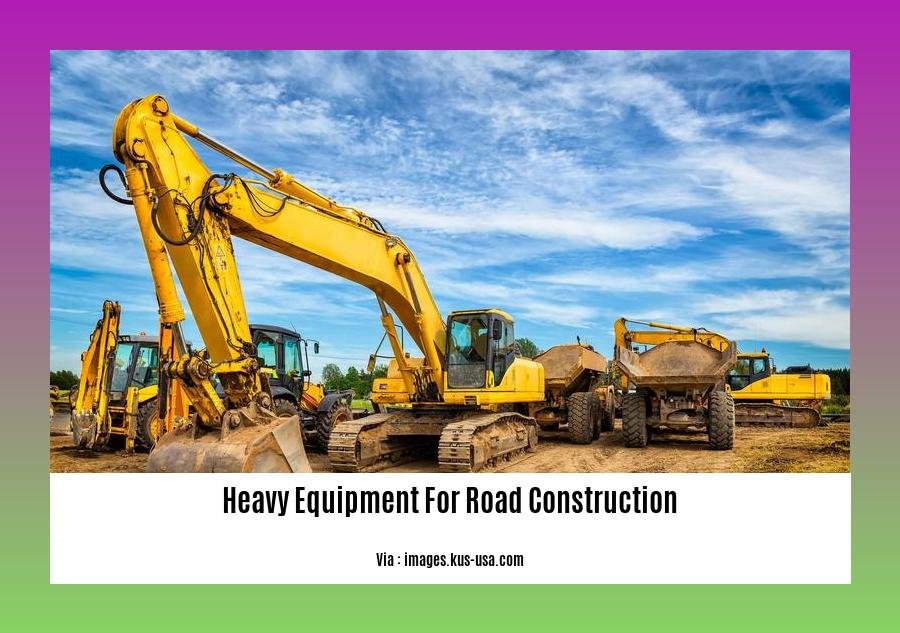

Discover the comprehensive guide to heavy equipment for road construction, tailored specifically to meet the demands of this critical industry. This guide will delve into the essential knowledge and insights you need to select, operate, and maintain the machinery that powers road construction projects, ensuring efficient, durable, and safe infrastructure development.

Key Takeaways:

- Heavy equipment is essential for efficient and enduring road construction.

- Key heavy equipment for road construction includes:

- Graders

- Excavators

- Loaders

- Asphalt pavers

- Considerations for selecting and operating heavy equipment include:

- Capabilities

- Limitations

- Safety

- Environmental impact

- Pavement quality

- Engineering software and industry standards ensure optimal equipment utilization.

Heavy Equipment for Road Construction: A Comprehensive Guide

Navigating the intricate world of road construction demands a comprehensive understanding of the indispensable tools that power this industry: heavy equipment. These machines, each tailored for specific tasks, play a critical role in delivering safe, durable, and efficient roadways.

Types of Heavy Equipment for Road Construction

A diverse array of heavy equipment ensures the smooth execution of various road construction processes. Let’s delve into some of the most common types:

- Excavators: Equipped with hydraulic arms and buckets, excavators excel at excavation, trenching, and loading.

- Bulldozers: These powerful machines utilize blades to level ground, remove debris, and compact soil.

- Graders: Graders precisely smooth and shape road surfaces, preparing them for paving.

- Wheel Tractor Scrapers: Designed for large-scale earthmoving, these machines efficiently transport vast amounts of soil or rock.

- Asphalt Pavers: As the name suggests, these machines lay asphalt evenly and precisely, creating smooth road surfaces.

Applications of Heavy Equipment in Road Construction

The versatility of heavy equipment extends to a multitude of tasks, enabling the efficient construction and maintenance of roads. These tasks include:

- Digging trenches and foundations

- Leveling and grading surfaces

- Compacting soil and asphalt

- Transporting materials

- Paving road surfaces

- Removing obstacles and debris

Selecting the Right Heavy Equipment

Choosing the appropriate heavy equipment is crucial for maximizing productivity and safety. Factors to consider include:

- Project Scope: Identify the specific tasks and site conditions involved in your project.

- Equipment Capabilities: Ensure the equipment you select aligns with the required tasks and operational environment.

- Safety Regulations: Comply with all safety regulations and guidelines for the operation and maintenance of heavy equipment.

Ensuring Safety and Efficiency

Operating heavy equipment demands a high level of skill and training. Adhering to the following best practices promotes safety and efficiency:

- Prioritize regular maintenance and inspections.

- Employ trained and certified operators.

- Establish clear communication channels on the construction site.

- Implement comprehensive safety measures, including proper signage, barriers, and emergency protocols.

By embracing these guidelines, you can harness the power of heavy equipment to deliver卓越的roadways that stand the test of time.

If you are looking to hire a health and safety officer in construction, we have a comprehensive guide that will help you understand the role and responsibilities

of this important position.

For those interested in heavy highway construction companies, we have compiled a list of leading companies in the industry, along with their capabilities and project portfolio.

If you need information on heavy machinery for road construction, our article provides detailed descriptions and specifications of different types of equipment used in road building and maintenance.

For those looking to explore the Indian construction market, we have a dedicated section on highway construction companies in india, providing insights into major players, their strengths, and notable projects.

For a comprehensive overview of highway construction procedure, our guide outlines the step-by-step process involved in highway development, from planning and design to construction and maintenance.

If you want to delve deeper into the highway construction process, we have a detailed article that explores the technical aspects, including materials, methods, and quality control measures.

Finally, for a concise guide on highway construction steps, our article provides a simplified breakdown of the key stages involved in highway construction, from earthwork to paving and finishing.

Operational Considerations for Heavy Equipment

Navigating the intricate world of heavy equipment operations requires a meticulous approach that ensures optimal performance, safety, and cost-effectiveness. Here’s a comprehensive guide to help you master these considerations:

Equipment Selection: The Perfect Fit

Choosing the right equipment for your project is paramount. Consider the scope, site conditions, and your intended tasks. Ensure the equipment’s capabilities align with your specific requirements, adhering to safety regulations for a seamless execution.

Maintenance: The Lifeline of Your Fleet

Regular maintenance is the cornerstone of equipment longevity and efficiency. Adhering to manufacturer guidelines and conducting thorough inspections will prevent breakdowns, minimize downtime, and enhance safety.

Operator Training: Empowered Expertise

Trained and certified operators are the gatekeepers of safe and efficient operation. Ensure your team undergoes comprehensive training programs tailored to the specific equipment they handle. This investment in knowledge pays dividends in enhanced productivity and reduced risk.

Safety First: An Unbreakable Bond

Safety is not an option but a non-negotiable priority. Implement clear communication protocols, establish safety barriers, and enforce emergency procedures. A culture of safety consciousness safeguards your team and minimizes the risk of accidents.

Key Takeaways:

- Prioritize equipment selection aligned with project requirements and safety standards.

- Maintain a disciplined maintenance schedule to ensure optimal equipment performance.

- Invest in comprehensive operator training to empower your team and enhance safety.

- Implement a robust safety program to protect your workforce and prevent accidents.

Relevant URL Sources:

- Safe Operation Of Heavy Equipment In 12 Steps – Work Safety QLD

- Tips for Safely Operating Heavy Equipment | Gregory Poole

Maintenance and Safety Guidelines

When it comes to road construction, heavy equipment is the backbone of our operations. It’s essential to keep this machinery in tip-top shape to ensure efficient and safe project execution. So, let’s dive into some crucial Maintenance and Safety Guidelines.

Maintenance Best Practices

- Regular Inspections: Conduct thorough inspections before each use to identify any potential issues early on.

- Preventive Maintenance: Implement a maintenance schedule to prevent breakdowns and extend equipment life.

- Uptime Maximization: Proper maintenance reduces downtime, keeping your equipment ready for action.

- Cost-Effective Replacement Plans: Monitor maintenance costs to determine optimal replacement schedules.

Safety First

- Train Like a Pro: Operators should receive proper training and certification for each type of equipment they operate.

- Safety Gear Protocol: Hard hats, safety glasses, gloves, and appropriate clothing are non-negotiable.

- Stay Alert: Be aware of your surroundings, potential hazards, and nearby workers.

- Follow the Rules: Adhere to traffic laws, speed limits, and worksite regulations.

- Clear Communication: Establish clear communication protocols and safety measures for your crew.

Key Takeaways:

- Regular maintenance and inspections are crucial for equipment longevity and productivity.

- Operators should be highly trained and follow safety protocols to minimize accidents.

- Proper maintenance and safety measures reduce downtime, save costs, and ensure project success.

Relevant URL Sources:

- Road Construction Equipment Maintenance Best Practices

- Heavy Equipment Safety: Hazards, Control Measures, and Types of Equipment

Advancements and Trends in Heavy Equipment

Prepare to immerse in an exploration of the Advancements and Trends in Heavy Equipment, reshaping the landscape of road construction. From automation to electrification, buckle up for an enlightening journey into the future of heavy machinery.

Automation in Construction:

- Autonomous vehicles and equipment are transforming construction sites, improving safety, efficiency, and accuracy.

- Advanced sensors, GPS technology, and AI enable machines to perform tasks with minimal human intervention.

Electrification of Construction Equipment:

- Electric-powered equipment is gaining momentum due to its environmental benefits and reduced operating costs.

- Zero-emission vehicles contribute to sustainable construction practices and improve air quality.

Tiltrotator Accessories:

- Tiltrotators, attachments that allow excavators to tilt and rotate their buckets, revolutionize digging operations.

- Enhanced maneuverability and precision increase productivity and reduce operator fatigue.

Market Expansion and Innovation:

- The construction machinery market is booming globally, driven by infrastructure development and urbanization.

- Cutting-edge technologies, such as IoT (Internet of Things) and data analytics, are setting new benchmarks in equipment performance.

Projections for the Future:

- The global heavy construction equipment market is projected to reach $273.5 billion by 2030.

- Continuous advancements in technology, sustainability, and automation will reshape the future of road construction.

Key Takeaways:

- Automation enhances safety, efficiency, and accuracy in construction.

- Electrification fosters sustainability and reduces operating costs.

- Tiltrotators improve maneuverability and productivity for excavators.

- The heavy equipment market is expanding rapidly, driven by innovation and demand.

- Projections indicate a promising future for heavy equipment in road construction.

Relevant URL Sources:

- 9 Emerging Trends in Construction Equipment: 2024 Outlook

- Heavy Construction Equipment Market Trends and Forecast 2030

FAQ

Q1: What are the different types of heavy equipment used in road construction?

Q2: How do you ensure the safe operation of heavy equipment on a road construction site?

Q3: What are the best practices for maintaining heavy equipment used in road construction?

Q4: What are the latest trends in heavy equipment technology for road construction?

Q5: What are the benefits of using heavy equipment in road construction projects?

– Heavy Equipment for Road Construction: Paving the Way for Infrastructure

Delve into the realm of road construction, where heavy equipment reigns supreme. In this article, [- Heavy Equipment for Road Construction: Paving the Way for Infrastructure], we explore the indispensable tools that shape our infrastructure, from graders that sculpt the earth to excavators that dig deep trenches and pavers that lay down the smooth asphalt we drive on. Get ready to discover the intricacies of these engineering marvels and their pivotal role in shaping our modern world.

Key Takeaways:

- Road construction requires specialized heavy equipment such as road rollers, wheel loaders, excavators, and forklifts.

- Heavy equipment enhances safety and efficiency by automating tasks and improving precision.

- Heavy equipment is essential for road building and rehabilitation, enabling large-scale operations and minimizing manual labor.

Road Construction Equipment

The construction of durable and efficient roads is made possible by utilizing specialized road construction equipment. With their advanced capabilities and precision engineering, these machines are designed to excel in various construction tasks, from earthmoving and grading to paving and finishing.

Types of Road Construction Equipment:

1. Graders:

– Level and shape unpaved surfaces

– Create slopes and embankments

– Handle fine grading tasks

2. Excavators:

– Dig trenches and foundations

– Remove soil, rock, and debris

– Handle loading and unloading operations

3. Loaders:

– Load materials into dump trucks or other vehicles

– Clear debris from construction sites

– Assist in excavation and grading tasks

4. Dump Trucks:

– Transport excavated materials and construction debris

– Dump loads at designated disposal sites

– Haul asphalt and concrete to paving areas

5. Pavers:

– Place and spread asphalt or concrete on road surfaces

– Ensure even distribution and smooth finishes

– Handle specialized paving techniques

Benefits of Using Heavy Equipment in Road Construction:

1. Enhanced Safety:

– Reduces manual labor and minimizes the risk of accidents

– Provides operators with better visibility and control

– Incorporates safety features such as roll-over protection structures (ROPS)

2. Increased Efficiency:

– Automates repetitive tasks, increasing productivity

– Allows for faster completion of construction projects

– Optimizes resource allocation and reduces downtime

3. Specialized Functions:

– Equipment is specifically designed for road construction applications

– Handles tasks that would otherwise be difficult or impossible to perform manually

– Ensures precision and accuracy in construction processes

By utilizing a comprehensive suite of road construction equipment, contractors can achieve maximum productivity, safety, and quality in their road construction projects. These machines are indispensable tools that have revolutionized the industry, paving the way for the development of durable and efficient transportation infrastructure.

If you’re looking to ensure the well-being of your construction site, connect with a certified health and safety officer in construction today.

For all your heavy construction needs, explore the services offered by heavy highway construction companies and find the perfect partner for your project.

Discover the latest and most efficient heavy machinery for road construction to enhance your project’s productivity and safety.

India’s infrastructure development is booming, and to keep up with the demand, highway construction companies in India are expanding their operations rapidly.

For a comprehensive understanding of the road construction process, refer to the detailed guide on highway construction procedure.

Gain insights into the step-by-step process involved in highway construction by exploring the informative guide on highway construction process.

Follow the essential steps outlined in the guide on highway construction steps to ensure a successful and efficient highway construction project.

Selection Considerations for Heavy Equipment: A Guide for Road Construction

In road construction, selecting the right heavy equipment is paramount. Here are critical factors to consider:

Cost and ROI

Understand the initial cost of the equipment, operating expenses, and potential return on investment. Equipment rental options can provide flexibility and reduce capital costs.

Productivity and Efficiency

Consider the equipment’s speed, capacity, and productivity rates. Choose equipment that aligns with your project requirements and deadlines.

Sustainability

Heavy construction can impact the environment. Opt for fuel-efficient models, consider noise levels, and explore renewable energy sources for equipment operation.

Safety

Ensure the equipment meets safety standards and regulations. Look for features like ROPS (Rollover Protective Structure) and FOPS (Falling Objects Protective Structure) to protect operators.

Availability and Support

Access to spare parts and qualified technicians is crucial for minimizing downtime. Consider equipment availability, local dealerships, and ongoing support from manufacturers.

Other Considerations

- Terrain and site conditions: Equipment must be suitable for the project’s terrain and soil conditions.

- Project size and duration: Choose equipment with the appropriate capacity and durability for the project’s scale and timeline.

- Transport and logistics: Consider the cost and feasibility of transporting and setting up equipment at the construction site.

Key Takeaways:

- Consider cost, ROI, productivity, sustainability, and safety when selecting equipment.

- Opt for equipment that aligns with the project’s size, terrain, and timeline.

- Explore rental options to reduce capital costs and increase flexibility.

- Give priority to equipment with advanced safety features and reliable support.

- Evaluate the environmental impact of the equipment and choose sustainable options.

Sources:

- Selection of Equipment for Construction of a Hilly Road Using Multi Criteria Approach

- Criteria for the Selection of Sustainable Onsite Construction Equipment

Environmental and Safety Concerns

In road construction, the impact on the environment and safety measures are paramount concerns. Minimizing environmental disturbances and ensuring the well-being of workers and the surrounding community are crucial aspects that require careful attention.

Environmental Concerns

Noise and Vibration:

Heavy equipment and construction activities can generate excessive noise and vibrations. Prolonged exposure can cause disturbance, damage structures, and affect wildlife. Adopting noise-reducing technologies, restricting work hours in sensitive areas, and installing noise barriers can mitigate these impacts.

Dust:

Construction activities create dust, which can lead to respiratory issues and reduced visibility. Implementing dust control measures such as wetting work surfaces, using dust collectors, and covering stockpiles can minimize dust generation.

Waste Management:

Road construction generates significant waste, including construction debris and contaminated soil. Proper waste management practices, such as recycling, reusing, and proper disposal, are crucial to prevent environmental pollution.

Road Materials and Furniture:

Road materials and furniture, like asphalt and concrete, can leach hazardous substances into groundwater and soil. Using eco-friendly materials, selecting sustainable pavement designs, and ensuring proper drainage systems can reduce these impacts.

Safety Concerns

Worker Safety:

Operating heavy equipment poses risks to workers. Implementing safety protocols, providing adequate training, and ensuring proper equipment maintenance are essential for preventing accidents and injuries.

Public Safety:

Road construction can disrupt traffic and affect public safety. Clear signage, traffic management plans, and proper barricading help ensure safety for motorists and pedestrians.

Key Takeaways:

- Noise and vibration mitigation measures, such as noise barriers and restricted work hours, protect the environment and communities.

- Dust control measures like wetting surfaces and using collectors minimize respiratory hazards.

- Waste management practices focus on recycling, reusing, and proper disposal to reduce environmental pollution.

- Eco-friendly road materials and sustainable pavement designs limit hazardous substance leaching.

- Safety protocols, training, and proper equipment maintenance prevent accidents and injuries on-site.

- Traffic management plans, signage, and barricading ensure public safety during road construction.

Relevant URL Sources:

- Environmental Issues Related to Road Management

- Analysis of Major Environmental Impact Categories of Road Construction

Advancements and Innovations in Heavy Equipment

The construction industry is continually evolving, and the equipment used in road construction is no exception. Advancements and Innovations in Heavy Equipment are transforming the way roads are built, from remote-controlled mining machines to self-driving pavers.

Remote-Controlled Machines

Mining equipment can now be operated remotely, reducing the risk to human operators and increasing productivity. This allows for more dangerous or inaccessible areas to be mined more safely and efficiently.

Connected Machines

Telematics and IoT connect heavy equipment to the internet, allowing for remote monitoring and data analysis. This information can be used to track machine performance, identify potential issues, and optimize maintenance schedules.

Autonomous Machines

Self-driving machines are becoming a reality, with applications in various construction tasks. These machines can operate without human involvement, increasing productivity, safety, and efficiency.

Predictive Analytics/Telematics

Telematics data and analytics can be used for predictive maintenance, allowing equipment managers to identify potential problems before they occur and schedule maintenance accordingly. This reduces downtime and keeps equipment running smoothly.

Electromobility

Electromobility is transforming construction equipment, reducing emissions and improving sustainability. While challenging for large machines, electric equipment is becoming more common, especially in urban and environmentally sensitive areas.

Key Takeaways:

- Remote-controlled machines enhance safety and efficiency in mining.

- Connected machines enable remote monitoring and data analysis for optimized performance.

- Autonomous machines increase productivity, safety, and efficiency.

- Predictive analytics helps reduce downtime by identifying potential problems in advance.

- Electromobility reduces emissions and improves sustainability in construction equipment.

Sources:

- Volvo CE Blog: Six Innovations Impacting the Future of Construction Equipment

- Hitachi Construction Machinery: The Future of Construction Equipment

FAQ

Q1: What types of heavy equipment are used in road construction?

A1: Road construction projects utilize a range of heavy equipment, including road rollers, graders, dump trucks, and asphalt pavers. Each type of equipment serves a specific purpose, such as preparing the roadbed, smoothing asphalt, and transporting materials.

Q2: How does heavy equipment enhance safety and efficiency in road construction?

A2: Heavy equipment plays a crucial role in improving safety and efficiency on road construction sites. By automating tasks and reducing manual labor, it minimizes risks to workers and increases overall productivity.

Q3: What are some of the challenges associated with selecting equipment for road construction projects?

A3: Selecting the appropriate heavy equipment for road construction projects requires careful consideration of factors such as cost, efficiency, productivity, and environmental impact. Choosing equipment that meets the specific requirements of each project is essential to ensure optimal performance.

Q4: How is technology transforming the future of heavy equipment in road construction?

A4: Technological advancements are revolutionizing heavy equipment in road construction. Innovations such as remote control operation, telematics, and autonomous machines are enhancing safety, efficiency, and data analysis capabilities.

Q5: What are the environmental considerations when using heavy equipment in road construction?

A5: When using heavy equipment in road construction, it is important to minimize environmental impact. This includes reducing noise and emissions, minimizing waste, and protecting groundwater and soil from contamination.

– Essential Heavy Equipment for Road Construction Projects: A Comprehensive Guide

Embark on a comprehensive journey into the realm of heavy equipment that forms the backbone of road construction projects. [- Essential Heavy Equipment for Road Construction Projects: A Comprehensive Guide] unveils the indispensable machinery used to shape, pave, and maintain our transportation arteries. From colossal excavators to meticulous asphalt pavers, discover the tools that transform blueprints into enduring roadways.

Key Takeaways

-

Road construction projects require a range of heavy equipment for efficient and effective execution

-

Road roller compacts soil and applies layers of materials

-

Wheel loader efficiently loads and hauls material

-

Excavator handles various tasks such as piling and moving earth materials

-

Excavator performs various tasks such as drilling holes and demolishing structures

-

Cold planers remove old layers before repaving roads

Heavy Equipment for Road Construction: A Comprehensive Guide

Essential Heavy Equipment

Heavy equipment is the backbone of road construction, enabling efficient, precise, and safe execution of various tasks. Here’s a rundown of the most essential heavy equipment for road construction:

- Road Roller: Compacts soil and asphalt, creating a smooth and solid surface.

- Wheel Loader: A versatile machine used for digging, loading, and transporting materials.

- Excavator: Excavating, lifting, and loading materials, it’s crucial for site preparation and material movement.

- Forklift: Lifts and transports materials within a worksite.

Additional Site Support Items

In addition to the core heavy equipment, several other items enhance construction efficiency:

- Asphalt Plant: Produces asphalt concrete, the material used in road surfaces.

- Truck Crane: Lifts heavy objects, facilitating equipment installation and material handling.

- Asphalt Pavers: Place asphalt precisely and evenly, creating a smooth road surface.

- Cold Planers: Remove existing asphalt, preparing the road for resurfacing.

Benefits of Heavy Equipment

Employing heavy equipment for road construction offers numerous benefits:

- Increased efficiency and speed, minimizing project timelines.

- Enhanced safety, reducing manual labor and potential hazards.

- Precision and accuracy, ensuring high-quality construction outcomes.

- Reduced labor costs, freeing up resources for other aspects of the project.

Safety Considerations

Operating heavy equipment requires strict adherence to safety protocols:

- Wear appropriate personal protective equipment (PPE).

- Inspect equipment regularly to ensure optimal condition.

- Follow operating procedures meticulously.

- Maintain awareness of surroundings and other personnel.

–

We also provide services related to construction engineering like – If you are in search of a health and safety officer in construction – refer to our experts at health and safety officer in construction. Their name is popping up in highway construction companies in india due to their excellent work in heavy machinery for road construction projects and in completing highway construction steps on time and with a team of experts from highway construction companies in india completing the project with great expertise and experience in highway construction procedure that no one can beat in the industry of highway construction process in india and around the world – the key to their success is their hard work and dedication towards their work and clients and this is the only highway construction process.

Applications and Industry Trends

Heavy equipment plays a critical role in the construction and maintenance of roads. Different types of equipment are used for various applications, from excavation and grading to paving and compaction. The construction industry is constantly evolving, and so is the equipment used in road construction.

Applications

- Earthmoving: Excavators, bulldozers, and scrapers are used to move large amounts of earth and prepare the ground for road construction.

- Paving: Asphalt pavers and concrete pavers are used to lay down new road surfaces.

- Compaction: Rollers are used to compact the soil and asphalt or concrete to ensure a smooth and durable surface.

- Maintenance: Graders, sweepers, and snowplows are used to maintain roads and keep them in good condition.

Industry Trends

- Automation and technology: The use of automation and technology in heavy equipment is increasing. This can lead to increased productivity, efficiency, and safety.

- Sustainability: The construction industry is becoming increasingly focused on sustainability, and this is also reflected in the development of heavy equipment. Many manufacturers are now producing equipment that is more fuel-efficient and environmentally friendly.

- Data collection and analysis: The use of data collection and analysis is becoming more common in the construction industry. This can help to improve project planning and execution, as well as equipment maintenance and safety.

Key Takeaways:

- Heavy equipment is essential for road construction and maintenance.

- Different types of equipment are used for various applications.

- The construction industry is constantly evolving, and so is the equipment used in road construction.

- Key industry trends include automation, technology, sustainability, and data collection.

Sources:

- The Role of Heavy Equipment in Road Construction

- Industry Trends Shaping the Future of Heavy Equipment

Maintenance and Safety Guidelines

Maintenance

- Regular inspections: Inspect equipment regularly to identify potential issues early on.

- Preventive maintenance: Follow manufacturer recommendations for preventive maintenance to avoid costly repairs.

- Scheduled maintenance: Implement a preventive maintenance schedule based on equipment usage and manufacturer guidelines.

- Equipment cleanliness: Maintain clean equipment to prevent malfunctions and improve performance.

- Proper storage: Store equipment in a dry and protected environment to prevent damage.

Safety

- Wear appropriate safety gear: Always wear personal protective equipment (PPE) such as hard hats, safety glasses, and gloves.

- Operate equipment safely: Follow operating procedures and never exceed manufacturer’s guidelines.

- Maintain situational awareness: Be aware of surroundings and potential hazards while operating equipment.

- Regular safety training: Provide regular safety training to equipment operators to ensure they are up-to-date on best practices.

- Emergency protocols: Establish clear emergency protocols and train operators on how to respond to accidents and breakdowns.

Key Takeaways:

- Implement regular inspections to prevent breakdowns.

- Follow manufacturer recommendations for preventive maintenance to reduce repair costs.

- Enforce safety protocols to protect operators and prevent accidents.

- Provide safety training to ensure operators are knowledgeable and prepared.

- Maintain clean equipment and proper storage to extend equipment lifespan.

Sources:

- Fleetio

- Occupational Safety and Health Administration

Future Advancements in Heavy Equipment Technology

Key Takeaways:

- Safety Enhancements: Proximity sensors improve safety by detecting potential hazards.

- Automation and Autonomy: Equipment capabilities are expanding with advancements in these areas.

- Telematics and Connectivity: Remote monitoring and predictive maintenance optimize uptime.

- Electrification: Environmental benefits and reduced operating costs make this technology increasingly relevant.

- Sustainability: Eco-friendly and emissions-reducing technologies prioritize environmental impact.

- Personalized Solutions: Manufacturers tailor solutions to specific customer needs and applications.

In the realm of road construction, future advancements in heavy equipment technology are revolutionizing the industry. These advancements not only enhance efficiency and safety but also pave the way for sustainable and cost-effective solutions. From autonomous equipment and electrified machinery to advanced sensors and data analytics, the future of road construction is poised for transformation.

1. Enhanced Safety and Automation

Safety remains a paramount concern in road construction. Future advancements in heavy equipment prioritize operator protection with proximity sensors that detect obstacles and potential hazards. Automation and autonomy reduce human error by handling repetitive tasks with precision, increasing safety on construction sites.

2. Telematics and Predictive Maintenance

Telematics and connectivity play a crucial role in optimizing equipment performance. Remote monitoring systems track machine health, allowing for predictive maintenance that identifies potential issues before they become major breakdowns. This proactive approach maximizes uptime and minimizes costly repairs.

3. Electrification and Sustainability

Electrification is gaining traction as a sustainable solution for road construction equipment. Electric vehicles and machines reduce emissions, lower fuel costs, and contribute to a greener work environment. Manufacturers are also developing eco-friendly technologies, such as biofuels and solar panels, to minimize the environmental impact of road construction.

4. Personalized Equipment Solutions

The future of road construction equipment also includes a focus on customization. Manufacturers are recognizing the need for solutions tailored to specific project requirements. By understanding the unique challenges and needs of different construction sites, they can provide equipment that is specifically designed to enhance productivity and efficiency.

As technology continues to evolve, the possibilities for future advancements in heavy equipment are endless. The road ahead for road construction is one of innovation, efficiency, and sustainability. By embracing these advancements, the industry can transform the way roads are built, ensuring a safer, more efficient, and greener future.

Relevant URL Sources:

- Inside Heavy Equipment Trends for 2024

- Heavy Equipment for Future of Construction: Technological Transformation

FAQ

Q1: What are the main types of heavy equipment used in road construction?

A1: Essential heavy equipment for road construction includes road rollers, wheel loaders, excavators, forklifts, asphalt plants, truck cranes, asphalt pavers, and cold planers.

Q2: What are the benefits of using heavy equipment in road construction?

A2: Heavy equipment increases efficiency and speed, improves safety, provides precision and accuracy, and reduces labor costs.

Q3: What safety considerations should be taken when using heavy equipment on road construction sites?

A3: It is crucial to wear appropriate PPE, inspect equipment regularly, follow operating procedures, and be aware of surroundings to ensure safety when using heavy equipment.

Q4: What are the key trends in the heavy construction equipment market?

A4: The global heavy construction equipment market is growing, driven by infrastructure development. Key trends include Indonesia’s market growth, key player dominance, and technological advancements.

Q5: What are the best practices for maintaining road construction equipment?

A5: Road construction equipment maintenance best practices include maximizing uptime, streamlining inspections, and adhering to preventive maintenance schedules. Expense calculation for replacement planning is also essential.

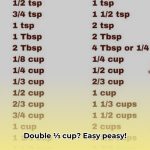

- Doubling 1/3 Cup: Quick Answer and Easy Kitchen Conversions - March 22, 2025

- J Middleton Unit (Abilene, TX): Inmate Search, Visitation, and Contact Information - March 22, 2025

- Ivermectin Dosage for Dogs: A Weight-Based Guide - March 22, 2025