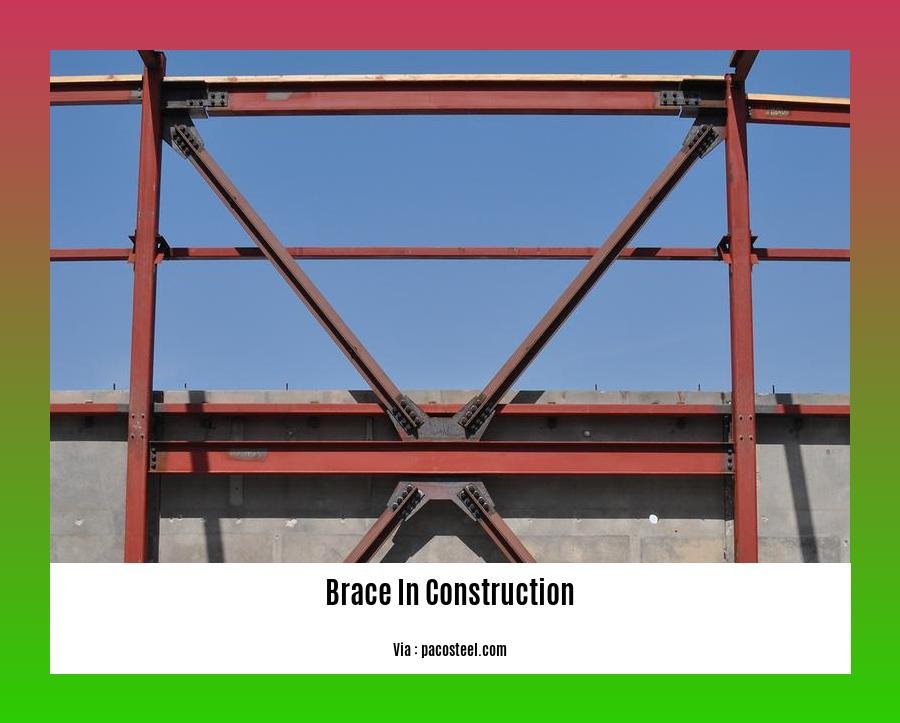

Braces in construction are essential for enhancing structural stability and safety. They play a vital role in resisting lateral forces, such as wind and seismic loads, and ensuring the integrity of buildings. From residential homes to towering skyscrapers, braces have become an indispensable element in modern construction practices. In this article, we will delve into the world of braces, exploring their types, applications, and the latest advancements that are shaping the industry.

Key Takeaways:

- Braces are supports used to enhance stability and safety in structures.

- Bracing systems improve earthquake resistance and overall performance of buildings.

- Wood or steel bracing elements increase stability.

- Braced frames are cost-effective and easily analyzed.

- Bracing is essential for earthquake-resistant construction.

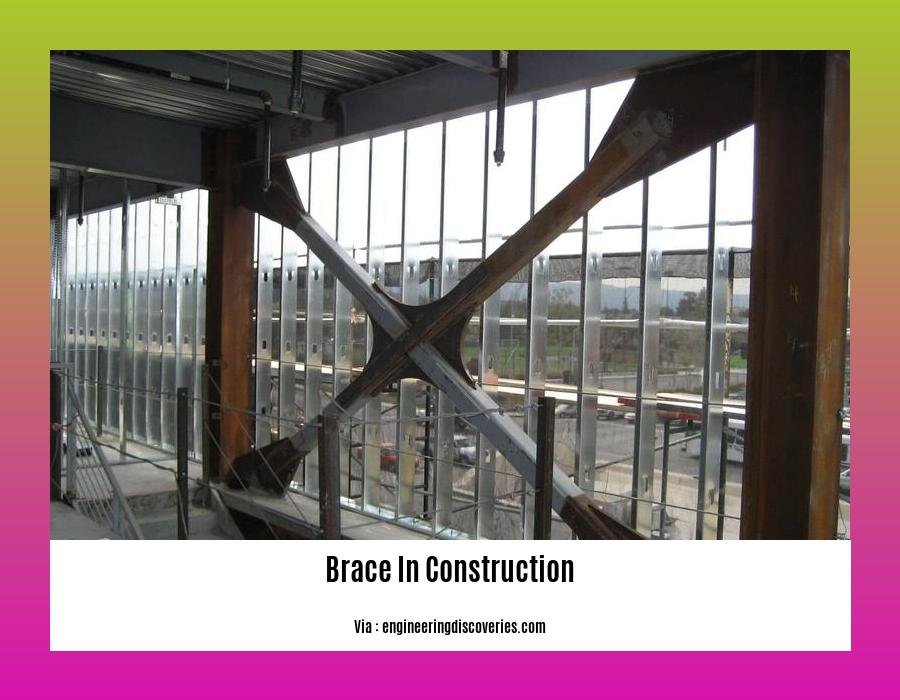

Braces in Construction

Braces are crucial components in construction, providing support and maintaining the integrity of structures. They are commonly utilized in buildings to distribute loads evenly and enhance safety, especially during seismic events. Braces can be made from various materials, including wood or steel, and are designed to resist lateral forces that could compromise the stability of a structure.

Types of Bracing Systems

- Diagonal Bracing: Consisting of diagonal members that extend from one end of a beam to the other, forming a triangle shape.

- Concentric Bracing: Involves a series of parallel braces arranged in a concentric pattern around the perimeter of a structure.

- Eccentric Bracing: Similar to concentric bracing, but the braces are positioned off-center within the structure.

- Shear Walls: Walls specifically designed to resist lateral forces, typically made from plywood or reinforced concrete.

Benefits of Bracing Systems

- Improved structural performance by evenly distributing loads

- Enhanced safety during earthquakes and other lateral events

- Cost-effective and easy to analyze compared to other structural systems

- Can be used in both residential and commercial constructions

- Contributes to the overall stability and integrity of buildings

Applications of Braces in Construction

Braces are widely used in various construction applications, including:

- Buildings in earthquake-prone regions

- High-rise structures

- Industrial facilities

- Bridges

- Retaining walls

Factors to Consider in Brace Design

- Material: The choice of material (wood or steel) depends on factors such as cost, strength requirements, and fire resistance.

- Configuration: The type of bracing system selected should be appropriate for the specific structural design and load requirements.

- Connections: The connections between braces and other structural elements must be strong and reliable to ensure the effectiveness of the bracing system.

- Codes and Regulations: It is essential to adhere to building codes and regulations that govern the design and installation of braces in construction.

-

Explore our comprehensive guide to hazardous materials on construction sites to ensure your project adheres to safety regulations and avoids potential risks.

-

Delve into the concept of harmonious construction, where architectural design blends seamlessly with its surroundings, creating aesthetically pleasing and sustainable structures.

-

Gain valuable insights into header in construction, a crucial component that provides structural support and defines the overall appearance of buildings.

Design and Analysis of Braces

Braces play a critical role in construction, providing structural stability and safety, especially during lateral events like earthquakes or high winds.

Key Takeaways:

- Bracing systems enhance structural performance, ensuring stability under horizontal forces.

- Design and Analysis of Braces involves understanding the type of bracing system, material properties, load requirements, and connection details.

- Braces can be made from angles, solid diaphragms, or other materials, and their design considers factors like stiffness, strength, and ductility.

- Engineers and fabricators collaborate to ensure proper Design and Analysis of Braces, ensuring optimal performance and safety.

Factors to Consider in Brace Design

- Type of Bracing System: Diagonal, cross, or other configurations, each with its advantages and applications.

- Material Properties: Strength, stiffness, and ductility of the bracing material, such as steel or wood.

- Load Requirements: Seismic or wind loads that the bracing system must resist, including magnitude and direction.

- Connection Details: Joints between braces and structural members, critical for transferring forces effectively.

Conclusion

Proper Design and Analysis of Braces is essential for the safety and integrity of structures, especially in regions prone to lateral forces. By considering these factors, engineers can ensure that bracing systems effectively resist horizontal loads, protecting lives and property.

Citations:

- American Institute of Steel Construction (AISC)

- Fundamentals of Beam Bracing | AISC

Installation and Maintenance of Braces

Over a decade in construction taught me how essential braces are when building or reinforcing a structure. These additional elements enhance stability and prevent collapse, especially during seismic and wind-related events.

Types of Braces

Bracing systems vary in shape, plane, and design:

- Diagonal Bracing: Most commonly used, these braces form an ‘X’ shape, providing support against lateral forces.

- Concentric Bracing: Consists of two parallel braces, one on each side of a column, providing high strength and stiffness.

- Eccentric Bracing: Similar to concentric bracing, but braces are offset from the column, creating a moment-resisting connection.

- Shear Walls: Vertical panels that resist lateral forces by transferring them to the ground.

Installation and Maintenance

Installation:

- Plan: Determine the appropriate type, size, and location of braces based on structural requirements.

- Fabricate: Braces are typically made of steel or wood, fabricated according to specifications.

- Install: Skilled professionals connect braces to structural members using bolts, welds, or other appropriate methods.

- Inspect: Conduct thorough inspections to ensure proper installation and adherence to building codes.

Maintenance:

- Regular Inspections: Inspect braces for rust, corrosion, or damage at least annually or as recommended by building codes.

- Tightening: Check and tighten loose bolts or connections to maintain structural integrity.

- Repairs: Promptly repair or replace any damaged braces to prevent further structural issues.

Benefits

Braces offer numerous benefits:

- Enhanced structural stability

- Improved resistance to lateral forces

- Increased safety during seismic events

- Compliance with building codes

Key Takeaways:

- Bracing systems provide stability and support against lateral forces.

- Types of braces vary based on shape, plane, and design.

- Proper installation and maintenance are crucial for long-term structural integrity and safety.

- Benefits include improved stability, resistance to lateral forces, and safety during seismic events.

URL Sources:

- American Institute of Steel Construction: Bracing Connections

- Steel Construction Institute: Bracing Systems

that technology-

FAQ

Q1. What are the primary functions of a bracing system in construction?

Q2. What are the factors considered in designing a bracing system?

Q3. How do bracing systems differ based on their plane or shape?

Q4. What are the benefits of incorporating smart technology into bracing systems?

Q5. How has 3D technology played a role in the modernization of brace design and production?

- The Best Battery Picture Lamps for Effortless Artwork Illumination - April 1, 2025

- Double Sink Bath Vanity Tops: A Buyer’s Guide - April 1, 2025

- Bath Towel Measurements: A Complete Guide to Choosing the Right Size - April 1, 2025