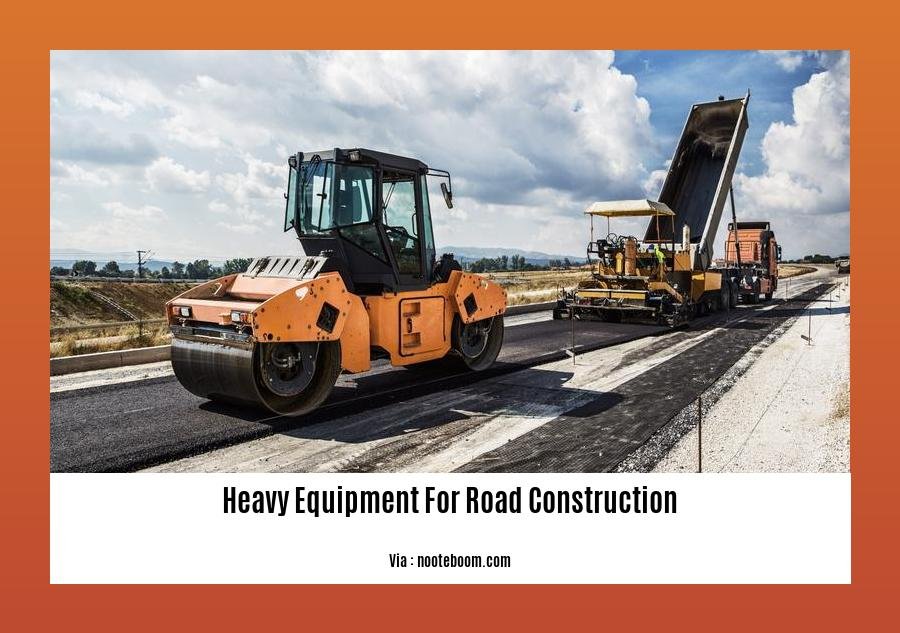

– Heavy Equipment for Road Construction: A Comprehensive Guide – Heavy equipment plays a pivotal role in the efficient and safe execution of road construction projects. This guide delves into the various types of heavy equipment used in road construction, their specific applications, and the factors to consider when selecting the appropriate equipment for different project requirements.

Key Takeaways:

- Essential Machinery: Road rollers, wheel loaders, excavators, and forklifts are crucial for road construction.

- Benefits of Heavy Equipment: Enhanced safety, efficiency, and precision.

- Additional Resources: Explore “The Most Practical Heavy Equipment for Road Construction” and “9 Common Machines For Road Construction” for further insights.

Heavy Equipment for Road Construction

Introduction

Heavy equipment for road construction plays a pivotal role in modern road building, enabling the efficient completion of complex construction tasks and enhancing safety standards across diverse terrains and climates.

Types of Heavy Equipment

The heavy equipment employed in road construction encompasses a wide range of machinery, each tailored to specific tasks. Vital types include:

-

Excavators excavate soil and rock, prepare trenches for utilities, and perform various earthwork operations.

-

Bulldozers clear land, level surfaces, and move materials, providing a solid foundation for road construction.

-

Graders shape and smooth road surfaces, ensuring a uniform and well-graded roadway.

-

Pavers lay asphalt or concrete, creating a smooth and durable road surface.

-

Comp unfinishedctors compress soil and asphalt, enhancing the stability and lifespan of the constructed road.

Benefits of Using Heavy Equipment

Leveraging heavy equipment in road construction offers significant advantages:

-

Efficiency: Automation and mechanization expedite tasks, enhancing productivity and reducing project timelines.

-

Safety: Equipment minimizes manual labor, reducing the risk of accidents and injuries.

-

Precision: Advanced technology ensures accurate grading, paving, and compaction, leading to superior road quality.

Conclusion

Heavy equipment is indispensable in modern road construction, enabling efficient, safe, and precise execution of complex tasks. By leveraging the capabilities of these machines, engineers can construct high-quality, durable roads that meet the demands of modern transportation.

-

Health and safety officers play a vital role in the construction industry, ensuring the well-being of workers and the overall safety of construction projects. Click here to learn more about the responsibilities and qualifications of a health and safety officer in construction. (health and safety officer in construction)

-

The heavy highway construction sector is one of the most important and demanding sectors of the construction industry. Click here to find out more about the top heavy highway construction companies in the industry and their expertise in building and maintaining our nation’s infrastructure. (heavy highway construction companies)

-

The construction of highways involves the use of specialized heavy machinery designed to handle the unique challenges of road construction. Click here to explore the different types of heavy machinery used in road construction and their applications in various phases of highway projects. (heavy machinery for road construction)

-

India has a vast network of highways that play a crucial role in the country’s economic development and social progress. Click here for a comprehensive overview of the leading highway construction companies in India, their capabilities, and their contributions to the nation’s infrastructure landscape. (highway construction companies in india)

-

Understanding the procedures involved in highway construction is essential for ensuring the quality, safety, and timely completion of these projects. Click here to delve into the detailed steps of highway construction, from planning and design to construction and maintenance. (highway construction procedure)

-

The process of highway construction involves a series of carefully orchestrated steps, each playing a critical role in the overall success of the project. Click here for a step-by-step guide to the highway construction process, from initial planning to final completion. (highway construction process)

-

Every highway construction project consists of a sequence of steps that must be meticulously followed to ensure the structural integrity and safety of the roadway. Click here for an in-depth analysis of the steps involved in highway construction, from preparation to completion. (highway construction steps)

Equipment Selection for Different Terrain and Project Requirements

As a seasoned civil engineer with extensive experience in road construction, I’ve encountered a diverse array of terrains and project demands. Equipment selection plays a pivotal role in ensuring efficiency, safety, and project success.

Terrain and Equipment Considerations

Terrain characteristics significantly influence equipment selection. For instance, mountainous areas may warrant excavators for rock excavation, while marshy terrain might require tracked dozer’s for better traction. Project requirements also impact equipment selection. High-volume road projects demand efficient pavers and compactors.

Equipment Types and Applications

Understanding the capabilities of different equipment types is crucial.

- Excavators: Versatile machines for digging, trenching, and loading.

- Dozer’s: Powerful machines for land-clearing, grading, and material movement.

- Graders: Used for shaping, smoothing, and maintaining road surfaces.

- Pavers: Lay asphalt or concrete pavement.

- Compactors: Compact soil and asphalt, increasing stability and density.

Equipment Selection Criteria

- Earthwork Operations: Excavators, dozer’s, and graders excel in earthwork operations like grading and trenching.

- Operational Efficiency: Consider fuel consumption, maintenance costs, and production rates to improve efficiency.

- Contractor Convenience: Prioritizing equipment availability, cost, and operator familiarity can enhance project execution.

Key Takeaways:

- Equipment selection aligns with terrain characteristics and project requirements.

- Understand the capabilities and applications of different equipment types.

- Consider earthwork operations, operational efficiency, and project convenience.

References:

- Planning and Selection of Heavy Construction Equipment

- Selection of Equipment for Construction of a Hilly Road Using Analytical Hierarchy Process (AHP) and Five CDM

Maintenance and Troubleshooting Guidelines

Ensuring the smooth functioning and longevity of your heavy equipment is paramount for efficient road construction. Here’s a comprehensive guide to help you maintain and troubleshoot these machines:

Maintenance Plan

- Regular Inspections: Schedule routine checks to identify potential issues early on. Use checklists to ensure all components are examined thoroughly.

- Preventive Maintenance (PM): Follow manufacturer recommendations for PM, which involves regular servicing, lubrication, and filter replacements.

- Condition Monitoring: Utilize sensors to monitor equipment health and identify potential problems before they become major issues.

PM Plan

- Asset Usage: Consider the equipment’s operating hours and load when planning PM intervals.

- Usage-based PM: Perform more frequent PMs for equipment operating under heavy loads or in harsh conditions.

- Condition-based Monitoring (CBM): Use sensors to detect changes in equipment performance and adjust PM schedules accordingly.

Outsourcing Maintenance

- Reduced Costs: Outsourcing can save you money by eliminating the need to invest in maintenance staff, tools, and parts inventory.

- Improved Availability: External providers often have access to a larger pool of resources, ensuring timely repairs and minimizing downtime.

- Safety and Compliance: Outsourcing to certified providers ensures compliance with safety regulations and industry best practices.

Key Takeaways:

- Regular inspections and preventive maintenance are crucial for equipment longevity.

- Condition monitoring and usage-based PM optimize maintenance schedules.

- Outsourcing maintenance can reduce costs, improve availability, and enhance safety.

Sources:

- Boom & Bucket

- Fleetio

Technological Advancements and Future Trends in Heavy Equipment

As we look towards the future of road construction, Technological Advancements and Future Trends in Heavy Equipment promise to revolutionize the industry:

Automation and Remote Control:

Operators can now control heavy machinery remotely, increasing safety and efficiency.

Electric and Hybrid Vehicles:

Environmental consciousness is driving the adoption of electric and hybrid vehicles, reducing emissions and noise pollution.

Data Analytics and Sensors:

Equipment is becoming increasingly connected, providing real-time data on performance, maintenance needs, and potential hazards.

Artificial Intelligence (AI):

AI algorithms are optimizing equipment performance, identifying potential problems, and enhancing safety protocols.

Augmented Reality (AR) and Virtual Reality (VR):

AR and VR are being used for training, maintenance, and remote troubleshooting.

Additive Manufacturing:

3D printing is enabling the production of complex parts and components, reducing lead times and costs.

Sustainability:

Heavy equipment manufacturers are focusing on reducing environmental impact through advancements in emissions control, fuel efficiency, and alternative energy sources.

Key Takeaways:

- Automation and remote control enhance safety and efficiency.

- Electric and hybrid vehicles reduce emissions and noise pollution.

- Data analytics and sensors optimize performance and safety.

- AI algorithms contribute to predictive maintenance and hazard identification.

- AR and VR enhance training and maintenance processes.

- Additive manufacturing speeds up production and reduces costs.

- Sustainability considerations drive advancements in emissions reduction and alternative energy sources.

Sources:

- Construction Equipment Market Size & Share Report, 2030

- Six Innovations Impacting the Future of Construction Equipment

FAQ

Q1: What is the most important benefit of using heavy equipment in road construction?

A1: Efficiency. Heavy equipment completes tasks faster and more efficiently than manual methods.

Q2: What are some of the most common types of heavy equipment used in road construction?

A2: Dozers, graders, excavators, loaders, and trucks.

Q3: What factors should be considered when selecting heavy equipment for road construction?

A3: Earthwork operations, operational efficiency, and contractor convenience.

Q4: What are some sustainable equipment considerations for road construction?

A4: Fossil fuel consumption and oil and lube leakage control.

Q5: What are the benefits of outsourcing heavy equipment maintenance?

A5: Reduced maintenance costs, improved equipment availability, and increased safety and compliance.

- The Best Battery Picture Lamps for Effortless Artwork Illumination - April 1, 2025

- Double Sink Bath Vanity Tops: A Buyer’s Guide - April 1, 2025

- Bath Towel Measurements: A Complete Guide to Choosing the Right Size - April 1, 2025