Dive into the [Advantages and Disadvantages of Modular Construction: A Comprehensive Guide] to explore this transformative approach to building design. As you delve into this definitive article, discover the benefits and drawbacks of modular construction, gaining invaluable insights into its revolutionary impact on the architecture industry.

Key Takeaways:

- Improved construction quality

- Reduced project costs

- Faster construction timelines

- Enhanced worker safety

-

Customizable interior design options

-

Limited flexibility in design modifications

- Potential size and land restrictions

- Financing challenges

-

Potentially lower resale value

-

Environmental considerations in material sourcing and energy efficiency

- Regulatory standards and building codes impact project feasibility

Advantages and Disadvantages of Modular Construction

As the construction industry embraces innovative solutions, modular construction has emerged as a promising approach that offers several benefits. However, it’s important to weigh these advantages against potential drawbacks to make informed decisions.

Advantages of Modular Construction

- Improved Quality: Factory-controlled environments allow for precise construction, minimizing errors and enhancing overall quality.

- Reduced Cost: Mass production and efficient design lower material and labor costs, resulting in significant cost savings.

- Faster Construction Time: Modules are prefabricated off-site, reducing on-site construction time.

- Enhanced Safety: Controlled factory conditions promote safer work environments, reducing the risk of accidents.

- Customizable Interiors: Modules offer flexibility in design, allowing for customization to meet specific requirements.

Disadvantages of Modular Construction

- Size and Land Restrictions: The size of modules can limit design options and require larger land parcels for assembly.

- Limited Flexibility: Modules are prefabricated, which may restrict design modifications during construction.

- Financing Challenges: Traditional lenders may be unfamiliar with modular construction, potentially leading to financing difficulties.

- Lower Resale Value: Modular homes may have a lower resale value compared to traditional construction.

Additional Considerations

Apart from the advantages and disadvantages of modular construction, other factors to consider include:

- Environmental Impacts: Modular construction can reduce waste and improve energy efficiency, but transportation and material choices need to be carefully assessed.

- Regulatory Standards: Ensure that the modular construction project meets all applicable building codes and regulations.

Ultimately, the suitability of modular construction depends on project-specific factors. By understanding the advantages and disadvantages discussed above, you can make informed decisions that balance benefits and drawbacks for your construction project.

Delve into the intricate details of aac blocks by clicking here to unravel their properties and applications.

Discover the intricate balance of advantages and disadvantages associated with prefabrication in the construction industry. Click here to explore this in-depth analysis.

Learn about the merits and drawbacks of steel frame construction by clicking here. This comprehensive guide will equip you with valuable insights.

Unveil the complexities of timber frame construction by clicking here. This exploration will shed light on its advantages and disadvantages.

Different types of modular construction, including volumetric modular construction and panelized construction

2D Modular Construction:

2D modular construction utilizes flat panels assembled on-site. It offers flexibility in design and easy logistics. In this method, prefabricated wall panels, floor panels, and roof panels are transported to the construction site and assembled like building blocks. This approach allows for customization and flexibility in design, making it suitable for various building types.

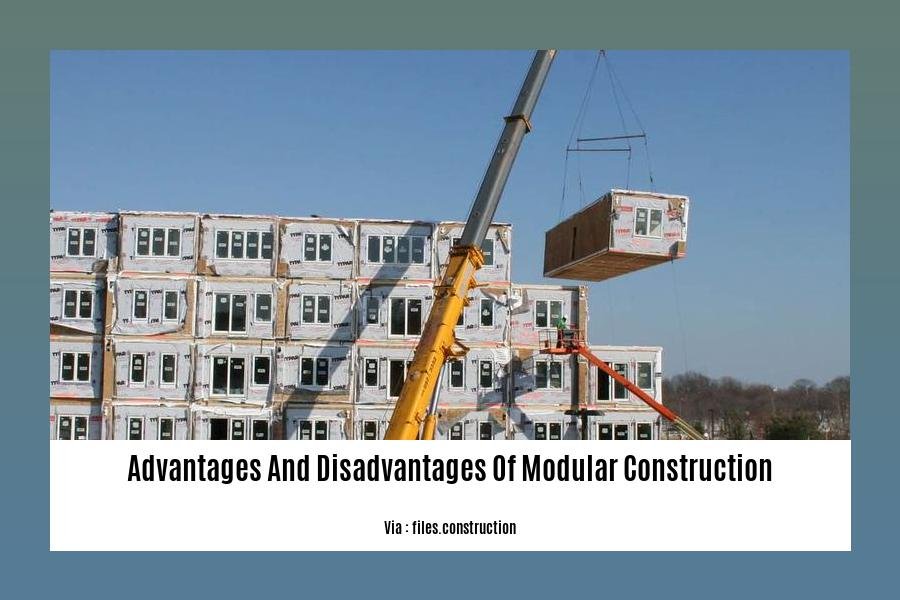

3D Modular Construction (Volumetric Modular Construction):

3D modular construction involves prefabricated volumetric modules, which are three-dimensional units that include walls, floors, and ceilings. These modules are assembled on-site, maximizing factory productivity and efficiency. Volumetric modular construction offers speed and efficiency, as the modules are largely completed in a controlled factory environment before being transported to the construction site for assembly.

Hybrid Modular Construction:

Hybrid modular construction combines elements of 2D and 3D modular construction. It provides flexibility and productivity benefits. Hybrid modular construction offers a balance between customization and efficiency, allowing for the integration of site-built elements with prefabricated modules.

Key Takeaways:

- Modular construction involves assembling prefabricated modules on-site, offering cost and time-saving benefits.

- 2D modular construction uses flat panels for assembly, providing design flexibility.

- 3D modular construction utilizes prefabricated volumetric modules, maximizing factory productivity.

- Hybrid modular construction combines elements of both 2D and 3D modular construction, offering flexibility and productivity benefits.

Relevant URL Sources:

- The Different Types of Modular Construction | Algeco

- The 3 Main Types of Modular Construction – Selo Group

Applications of modular construction in various industries, such as multi-family housing, commercial offices, and healthcare facilities

Modular construction is making waves across various industries, transforming the way we build and design structures. This innovative approach offers a range of benefits, including reduced construction time, cost savings, and improved quality control.

Multi-Family Housing:

Modular construction is revolutionizing the multi-family housing sector, enabling the rapid creation of affordable, high-quality apartment complexes. By prefabricating units in a controlled factory environment, modular construction ensures consistency, durability, and energy efficiency. This approach offers numerous advantages, such as faster move-in times, reduced noise pollution during construction, and minimized disruption to existing communities.

Commercial Offices:

Modular construction is transforming the commercial office landscape, providing businesses with flexible and adaptable workspaces. Prefabricated office modules allow for quick assembly, allowing companies to scale their operations rapidly and efficiently. This approach offers benefits such as reduced construction time, cost savings, and the ability to create customized office environments that meet specific business needs.

Healthcare Facilities:

Modular construction is also gaining traction in the healthcare industry, enabling the rapid construction of hospitals, clinics, and other healthcare facilities. By prefabricating standardized modules in a controlled environment, modular construction ensures infection control, reduces construction time, and minimizes disruption to patient care. This approach allows healthcare providers to expand their facilities quickly and efficiently, meeting the growing demand for healthcare services.

Key Takeaways:

- Modular construction offers a range of benefits, including reduced construction time, cost savings, and improved quality control.

- It is particularly well-suited for multi-family housing, commercial offices, and healthcare facilities.

- Modular construction enables the rapid creation of affordable, high-quality housing, adaptable workspaces, and efficient healthcare facilities.

Most Relevant URL Sources:

– McKinsey & Company: Modular Construction: From Projects to Products

– ScienceDirect: Modular Buildings in Modern Construction

Considerations for Evaluating the Suitability of Modular Construction for Specific Projects

Modular construction offers numerous advantages, but it’s important to assess its suitability for specific projects. Here are key factors to consider:

-

Project Size and Complexity: Modular construction excels in large, repetitive projects with standardized designs. Complex structures with unique architectural features may be less suitable.

-

Site Logistics: Ensure adequate space for module delivery, assembly, and storage. Consider site access, slopes, and overhead obstacles.

-

Transportation Consider the distance between the module manufacturing facility and the construction site. Logistics and transportation costs can impact project feasibility.

-

Design Limitations: Factory-produced modules have size and shape limitations. Evaluate whether the desired design can be accommodated within these constraints.

-

Cost Considerations: Initial investment in modular construction can be higher. Factor in transportation, assembly costs, and any potential cost savings over the long term.

-

Availability of Skilled Labor: Ensure the availability of experienced professionals for module installation and assembly. Local labor regulations and union requirements should be considered.

-

Regulatory Compliance: Modular construction must adhere to all relevant building codes and standards. Local authorities should be consulted for specific requirements.

Key Takeaways:

- Assess the project’s size, complexity, and site logistics.

- Consider transportation costs and design limitations.

- Evaluate cost implications and labor requirements.

- Ensure compliance with building codes and standards.

Relevant URL Sources:

- Modular Construction: Considerations for Project Suitability

- Evaluating the Suitability of Modular Construction for Specific Projects

FAQ

Q1: What are the primary advantages of modular construction?

A1: Modular construction offers several advantages, including improved quality control, reduced construction costs, faster project completion time, enhanced safety, and customizable interiors.

Q2: Are there any limitations or drawbacks to modular construction?

A2: While modular construction provides numerous benefits, it also has certain drawbacks, such as size and land restrictions, limited flexibility in design, financing challenges, and potentially lower resale value compared to traditional construction methods.

Q3: How does modular construction impact environmental sustainability?

A3: Modular construction promotes sustainable building practices by utilizing prefabricated components, reducing waste, and optimizing energy efficiency. Factory-controlled environments allow for precise material usage and minimize environmental impact during construction.

Q4: What are the different types of modular construction methods?

A4: Modular construction encompasses various methods, including 2D modular construction using flat panels, 3D modular construction using volumetric modules, and hybrid modular construction that combines elements of both approaches. Each method offers unique advantages and suits specific project requirements.

Q5: How does modular construction address regulatory standards and inspections?

A5: Modular construction adheres to the same regulatory standards and inspections as traditional construction methods. Building codes and permits apply equally to both approaches. Prefabricated modules are subject to rigorous quality control during manufacturing, ensuring compliance with building regulations.

- Small Corner Kitchen Ideas: Maximize Style In Tight Spaces - January 1, 2026

- Kitchen Counter Corner Ideas: Style Your Awkward Angles Now - December 31, 2025

- Best Finish for Butcher Block Countertops: Choosing the Right Option - December 30, 2025