Welcome to the comprehensive guide for engineers on highway construction procedures. This article will delve into the intricacies of highway construction, providing you with a thorough understanding of the essential steps involved in this critical infrastructure development process. From the initial planning and design stages to the final construction and inspection phases, we will explore the materials, techniques, and regulatory considerations that ensure the successful completion of highway projects. Embark on this comprehensive journey to enhance your knowledge and expertise in highway construction.

Key Takeaways:

- Understand the sequential steps involved in highway construction: Planning, Setting Out, Earthworks, Paving, Quality Control, and Traffic Control Plan.

- Recognize the significance of transferring design proposals accurately from drawings to the construction site during Setting Out.

- Earthworks encompass essential tasks like excavation, grading, and soil stabilization to prepare the ground for paving.

- Paving involves laying the road surface, utilizing materials like asphalt or concrete.

- Quality Control ensures compliance with specifications and standards throughout the construction process.

- Proper implementation of a Traffic Control Plan is crucial for managing traffic safely during construction activities.

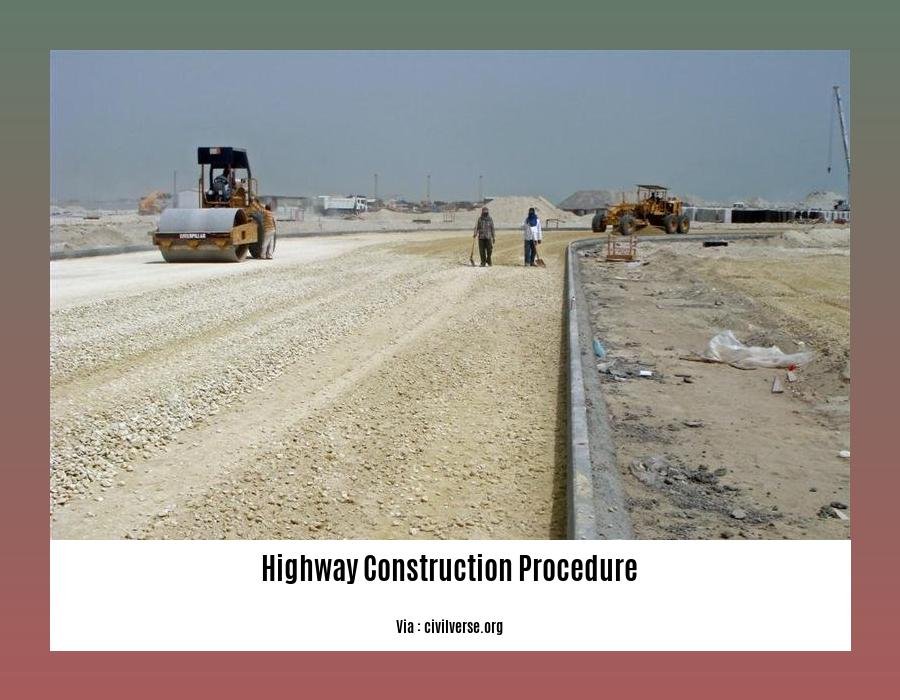

Highway Construction Procedure

After the planning phase, setting out involves transferring design proposals from drawings onto the ground. This crucial step ensures accurate alignment and layout of the highway.

Next, prepare the ground for paving through earthworks. This involves excavation, grading, and soil stabilization. Proper execution of earthworks lays the foundation for a stable and durable highway.

The paving stage involves laying the pavement, typically composed of asphalt or concrete. The choice of material depends on factors like traffic volume, environmental conditions, and cost.

Throughout the highway construction procedure, maintaining quality is paramount. Quality control measures ensure that the road meets specifications and standards, ensuring safety and longevity.

Finally, a traffic control plan establishes protocols for managing traffic during construction. This plan minimizes disruptions and ensures the safety of workers and motorists.

Remember, following these steps is not a one-time event but an ongoing process. Regular maintenance and inspections are essential to ensure the highway’s continued performance and safety.

Additional Tips for Highway Construction:

- Use high-quality materials to ensure durability and longevity.

- Employ experienced and qualified personnel for all phases of construction.

- Adhere to industry standards and best practices for quality control.

- Implement effective traffic management plans to minimize disruption and accidents.

- Monitor the highway’s performance and make necessary repairs and upgrades regularly.

-

For those in the market for reliable highway construction services in India, this page offers a comprehensive directory of reputable companies.

-

If you’re unfamiliar with the highway construction process, this detailed guide will illuminate each step of this intricate undertaking.

-

For a comprehensive breakdown of the highway construction steps involved, refer to this informative article outlining every stage of the project.

Construction and Installation

Are you ready to delve into the fascinating world of highway construction? As we embark on this journey, I’ll guide you through the intricacies of building highways, ensuring you grasp the fundamentals.

Let’s dive right in!

Understanding the Procedure

1. Planning

A blueprint for success! This initial stage lays the groundwork for the entire project, considering factors like traffic patterns, environmental impact, and cost.

2. Setting Out Design Proposals

Time to bring the blueprint to life! Engineers meticulously mark out the highway’s alignment on the ground, ensuring precision.

3. Earthworks

Prepare the ground for paving by excavating, grading, and stabilizing the soil. Think of it as creating a solid foundation for your highway.

4. Paving

Now, let’s lay the pavement! This protective layer withstands traffic and the elements, typically made of asphalt or concrete.

5. Quality Control

Every step of the way, it’s crucial to ensure the highway meets safety and durability standards. Engineers conduct thorough inspections to guarantee your smooth ride.

Key Takeaways:

- India proudly boasts the world’s second-largest road network.

- Drainage systems are essential for a highway’s longevity, preventing pavement failures.

- The construction process involves various layers, each with specific materials like soil, aggregate, and bitumen.

Relevant URL Sources:

- Road Construction Procedure: Easy Step-by-Step Guide

- Road Construction: Step-by-Step Process

Inspection and Testing in Highway Construction

When it comes to highway construction, inspection and testing are crucial steps in ensuring the safety, quality, and longevity of these critical infrastructure projects. These processes involve a rigorous evaluation of materials, construction methods, and adherence to standards to guarantee that the highways meet the required specifications and performance criteria.

Key Steps in Inspection and Testing

-

Materials Inspection: This involves examining the quality and properties of construction materials such as asphalt, concrete, soil, and aggregates. It ensures that the materials meet the specified standards and are suitable for their intended use.

-

Construction Method Inspection: Inspectors observe and monitor the construction methods employed during highway construction, verifying that they comply with established procedures and specifications. This includes inspecting equipment, techniques, and safety protocols.

-

Quality Control Testing: This involves conducting tests on samples of materials and finished work to assess their strength, durability, and performance. Tests may include pavement density, concrete compressive strength, and asphalt content analysis.

-

Performance Monitoring: Post-construction monitoring involves regular inspections to assess the highway’s performance over time. This helps identify any potential issues or deterioration that may require maintenance or repairs.

Benefits of Inspection and Testing

- Ensures compliance with industry standards and regulations.

- Verifies the quality and safety of construction materials and methods.

- Helps detect and address potential problems during construction.

- Provides documentation and evidence of construction practices.

- Improves the overall durability and longevity of highways.

Key Takeaways:

- Inspection and testing are essential aspects of highway construction, ensuring the safety, quality, and performance of these critical infrastructure projects.

- Materials, construction methods, and finished work must be thoroughly inspected and tested to meet specific standards.

- Regular monitoring allows for the early detection and resolution of highway issues, extending their lifespan.

- Inspection and testing procedures provide valuable documentation for project quality control and legal purposes.

Citation:

- National Institute for Certification in Engineering Technologies: Highway Construction Inspection

- American Association of State Highway and Transportation Officials (AASHTO): Standard Specifications for Transportation Materials and Methods of Sampling and Testing

Maintenance and Repairs

Safeguarding Your Highway Network

Roads are the arteries of our transportation system, and their maintenance is crucial for ensuring smooth and safe travel. Proper maintenance and repairs extend the lifespan of our highways, preventing premature deterioration and costly reconstruction.

Types of Maintenance

Highway maintenance encompasses a range of activities, from routine inspections to major repairs.

-

Routine maintenance: This includes tasks like cleaning drains, inspecting pavement, and trimming vegetation. Regular maintenance helps prevent minor issues from escalating into major problems.

-

Periodic maintenance: As roads age, they require more extensive repairs. Patching potholes, sealing cracks, and resurfacing the pavement fall under this category.

-

Special repairs: Major accidents, natural disasters, or severe deterioration may necessitate extensive repairs. These may involve replacing entire sections of the road or rebuilding bridges.

Importance of Regular Maintenance

Regular maintenance plays a pivotal role in highway longevity and safety. It:

- Prevents premature deterioration, saving significant repair costs.

- Keeps roads safe for drivers and pedestrians alike.

- Minimizes traffic disruptions caused by road closures for repairs.

- Enhances overall aesthetics and property values along the highway.

Standards and Regulations

To ensure uniformity and quality, road maintenance follows strict standards. These standards cover everything from road roughness limits to guidelines for materials and construction techniques. Adhering to these standards helps maintain the integrity and safety of our highway network.

Key Takeaways:

- Routine and periodic maintenance are essential for prolonging highway lifespan.

- Special repairs are necessary to address major damage or deterioration.

- Regular maintenance prevents minor issues from becoming costly problems.

- Adhering to standards ensures uniform quality and safety on all highways.

Citations:

- Highway Maintenance: Purpose, Types, and Components:

- Maintenance of Highways – Roads:

FAQ

Q1: What are the key steps involved in highway construction?

A1: The key steps in highway construction include planning, setting out, earthworks, paving, and quality control.

Q2: What materials are commonly used in highway construction?

A2: Common materials used in highway construction include soil, aggregates, asphalt, concrete, and admixtures.

Q3: How is traffic managed during highway construction?

A3: Traffic management during highway construction involves implementing a traffic control plan that includes measures such as flaggers, signs, and detours.

Q4: What are the environmental considerations in highway construction?

A4: Environmental considerations in highway construction include erosion control, water quality protection, and wildlife habitat preservation.

Q5: How is the quality of highway construction ensured?

A5: The quality of highway construction is ensured through inspections and testing throughout the construction process to verify compliance with specifications and standards.

- The Best Battery Picture Lamps for Effortless Artwork Illumination - April 1, 2025

- Double Sink Bath Vanity Tops: A Buyer’s Guide - April 1, 2025

- Bath Towel Measurements: A Complete Guide to Choosing the Right Size - April 1, 2025