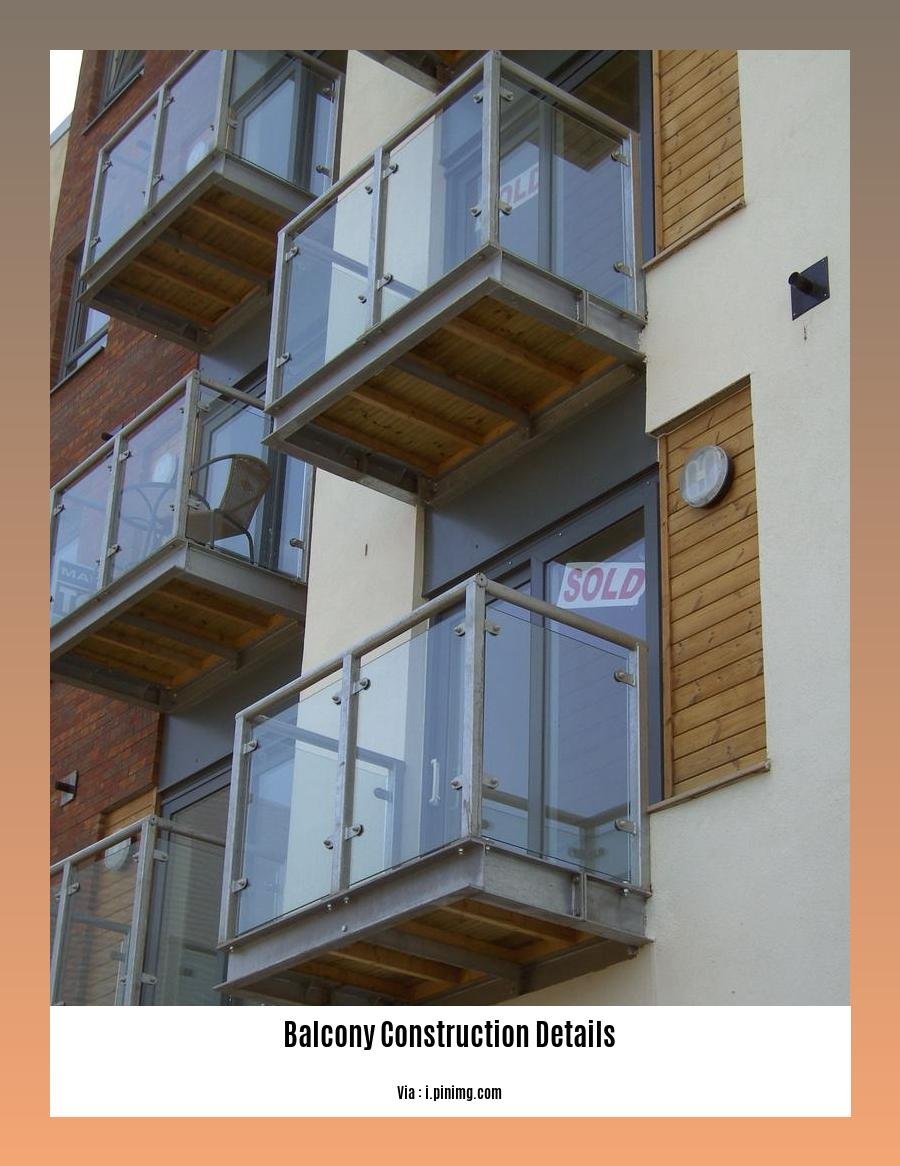

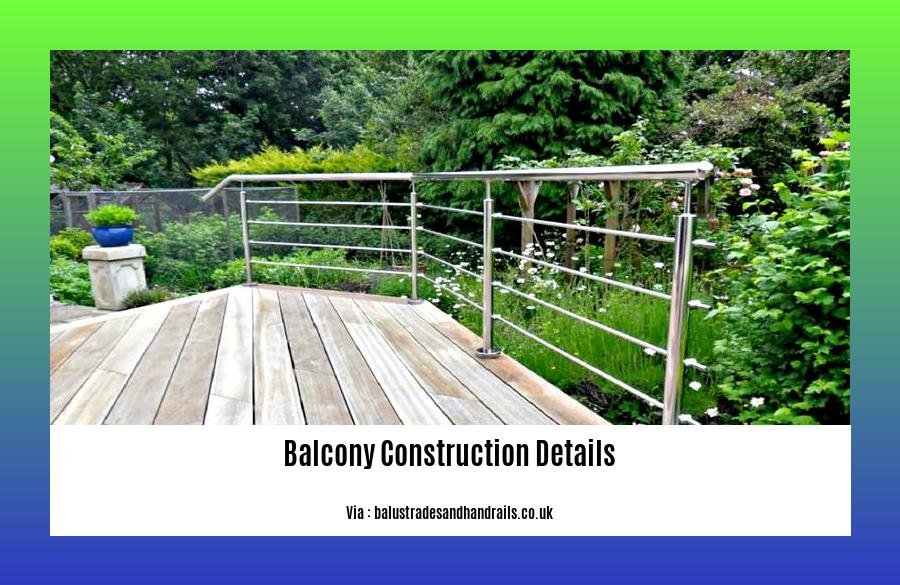

Balcony construction details require meticulous planning and execution to ensure structural integrity, aesthetic appeal, and occupant safety. Key considerations include material selection, load-bearing capacity, drainage systems, and safety features.

Key Takeaways:

-

Design and Planning:

- Determine balcony size and location based on building regulations and load requirements.

- Plan for drainage, ventilation, and safety features.

-

Materials:

- Use suitable materials for framing, decking, railings, and hardware.

-

Installation:

- Install joists, subflooring, railing support posts, handrails, and flooring in a safe and secure manner.

- Waterproof and seal the balcony for protection.

-

Additional Considerations:

- Ensure fall prevention measures with proper railing height and strength.

- Allow for airflow to prevent moisture buildup.

- Determine the load-bearing capacity of the building and balcony.

- Provide outlets and drainage for convenience and maintenance.

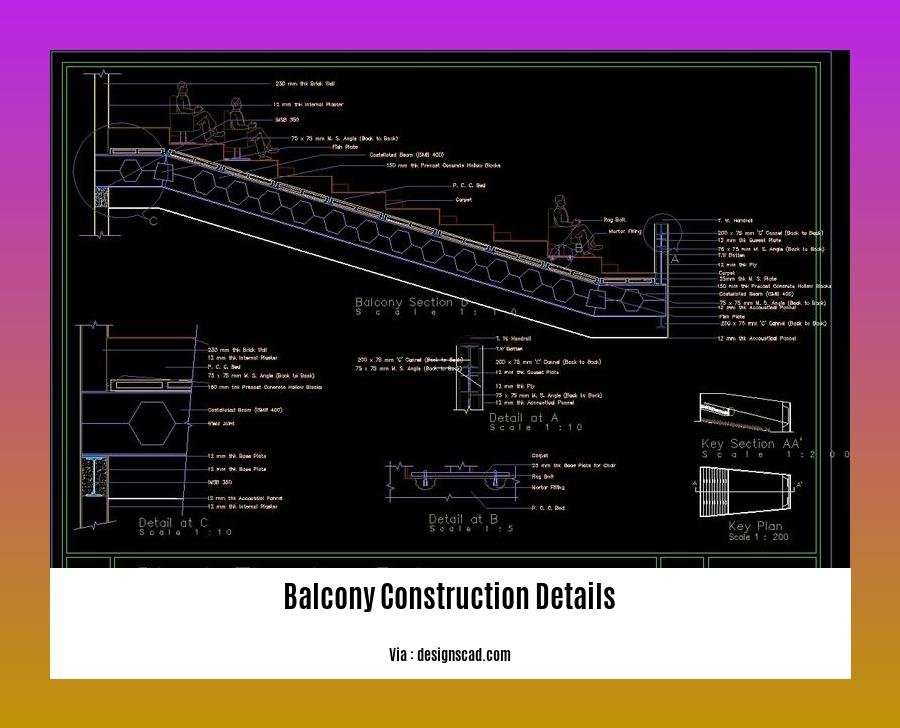

Balcony Construction Details

Balconies offer an extension of living space, adding aesthetic charm and enhancing the enjoyment of outdoor environments. However, constructing balconies demands meticulous attention to details to ensure safety, durability, and visual appeal.

Framing and Structural Considerations:

- Determine balcony size and shape: Consider the available space, intended use, and aesthetic preferences.

- Plan for load requirements: Calculate the live and dead loads the balcony will bear, ensuring it meets building codes and structural integrity standards.

- Use appropriate framing materials: Choose pressure-treated wood, composite materials, or steel for framing, depending on the design and load requirements.

- Provide proper ventilation: Allow for airflow to prevent moisture accumulation and premature deterioration.

Decking and Railings:

- Select durable decking materials: Opt for composite decking, natural wood, or concrete that can withstand harsh weather conditions and wear and tear.

- Ensure proper drainage: Incorporate drainage systems to drain water away from the balcony surface, preventing water damage.

- Install safety railings: Choose railings made of aluminum, vinyl, or wrought iron that meet building codes for height, spacing, and strength.

- Consider aesthetic appeal: Select railings that complement the overall architectural style of the building and enhance the balcony’s visual impact.

Materials and Hardware:

- Use quality materials: Choose high-quality materials for all components, including framing, decking, railings, and hardware, to ensure longevity and minimize maintenance.

- Select appropriate hardware: Use bolts, screws, and nails specifically designed for balcony construction, ensuring a secure and durable connection.

- Waterproofing and Sealing: Apply waterproof coatings or membranes to protect the balcony surface from water damage.

- Incorporate fall prevention measures: Ensure railing height and strength meet safety standards to prevent falls.

Additional Considerations:

- Plan for electrical outlets and lighting: Provide electrical outlets for lighting and appliances, enhancing convenience and outdoor enjoyment.

- Incorporate drainage systems: Install drainage systems to prevent water buildup, protecting the balcony from moisture damage.

- Consider privacy: Use privacy screens or planting boxes to create privacy and seclusion on the balcony.

- Regular maintenance: Establish a regular maintenance schedule to inspect, clean, and repair any issues that may arise, ensuring the balcony’s longevity and safety.

Are you curious about the latest trends in construction? Check out our article on the 5 marla house construction cost in Pakistan 2023 to stay informed about the costs associated with building a home. To gain insights into optimizing construction efficiency, we recommend reading our piece on basic concept in construction productivity enhancement. For an introduction to construction terminology, explore our article on bbm full form in construction and bbs meaning in construction. Additionally, for a comprehensive understanding of structural components, refer to our article on the beam in construction meaning.

Material Selection and their Pros and Cons

When it comes to balcony construction, choosing the right materials is crucial for both aesthetics and functionality. Here are some key considerations:

Aluminum

Pros:

– Lightweight and durable

– Corrosion-resistant

– Low maintenance

– Sustainable (can be recycled)

Cons:

– Can be expensive

– Susceptible to denting

Steel

Pros:

– Strong and sturdy

– Fire-resistant

– Cost-effective

Cons:

– Prone to rust

– Requires regular maintenance

Stainless Steel

Pros:

– Highly corrosion-resistant

– Durable and long-lasting

– Aesthetically pleasing

Cons:

– More expensive than other materials

– Can be difficult to weld

Hybrid Approach

To optimize performance, consider using a combination of materials. For example:

- Aluminum for the main structure due to its lightness and durability

- Stainless steel stubs for areas exposed to harsh elements

This approach balances cost, strength, and aesthetic appeal.

Key Takeaways:

- Aluminum is sustainable and requires low maintenance.

- Steel is strong and cost-effective.

- Stainless steel is durable and corrosion-resistant.

- A hybrid approach can combine the benefits of different materials.

- Material selection should align with budget, aesthetics, and functional requirements.

Relevant Sources:

- Sapphire Balconies: Industry Leader in Balcony Design – Material Selection for Balcony Design

- Choosing the Right Materials for Balcony Design – Design Café

Connections and Reinforcement Strategies:

Connections:

Connections play a crucial role in ensuring the stability and safety of cantilevered balconies and other building elements that penetrate a building’s thermal envelope. Halfen’s HIT Insulated Balcony Connection System is an innovative solution that minimizes thermal transfer in concrete cantilever balconies.

Reinforcement Strategies:

Balcony connectors must be effectively thermally separated, quickly installed, and protect against thermal bridging. Continuous thermal bridging is avoided by using steel sections bolted back to the structure instead of continuous reinforced concrete. Steel conducts heat more readily than concrete, but individual steel sections create a lesser thermal bridge than continuous concrete.

Key Takeaways:

- Thermal separation is essential for balcony connectors to prevent heat loss.

- Quick installation is crucial for efficient construction.

- Prevention of thermal bridging ensures energy efficiency and structural integrity.

Relevant Sources:

- Halfen HIT Insulated Balcony Connection System

- Balcony Connectors – Thermal Separation

Safety Regulations and Inspection Guidelines

Ensuring the safety and structural integrity of balconies is paramount, which is why strict Safety Regulations and Inspection Guidelines must be meticulously followed during construction and maintenance. These guidelines ensure that balconies are designed and built to withstand various loads, prevent falls, and maintain their structural integrity over time.

Structural Requirements

- BS/EN Standards: BS 5080, BS EN 1090, and BS EN 1990:2005 provide comprehensive guidelines for structural design and integrity, including load-bearing capacity and deflection limits.

- CE Marking: Indicates compliance with European safety standards, assuring the quality and safety of balcony components and construction.

Height and Safety Regulations

- Balustrade and Railing Height: Railings must meet specific height requirements to prevent falls. BS 8579: 2020 provides detailed guidelines on railing design and height for various balcony configurations.

- Safety Barriers: Balconies must incorporate safety barriers, such as screens or covers, to prevent children from climbing or falling over railings.

Building Codes and Inspections

- Local Building Codes: Local building codes enforce minimum safety standards for balconies, including load-bearing capacity, railing height, and materials used.

- Balcony Inspection Checklist: A comprehensive checklist outlines the specific areas to be inspected, including railings, decking, and drainage.

- Regular Inspections: Regular inspections are crucial to identify potential hazards and ensure the ongoing safety and structural integrity of balconies.

Inspection Process

- Visual Inspection: Inspect balconies for any visible cracks, corrosion, or damage to railings, decking, and supports.

- Load Testing: Conduct load tests to verify the balcony’s ability to withstand specified loads.

- Drainage Evaluation: Ensure proper drainage to prevent water accumulation and potential damage.

- Railing Strength: Test the strength of railings to ensure they meet safety standards and prevent accidental falls.

Key Takeaways:

- Adherence to Safety Regulations and Inspection Guidelines is crucial for ensuring the safety and structural integrity of balconies.

- Building codes and safety standards provide comprehensive guidelines for balcony design and construction.

- Regular inspections help identify potential hazards and maintain the structural integrity of balconies.

Relevant URL Sources:

FAQ

Q1: What are the primary considerations for determining balcony size and location?

Q2: How should I choose the most suitable materials for my balcony, balancing factors like sustainability, fire safety, and cost?

Q3: Can you provide guidance on designing balconies for optimal drainage and ventilation?

Q4: What are the critical safety measures I need to implement to prevent falls and accidents on my balcony?

Q5: Are there any specific building codes or regulations I should be aware of when constructing a balcony?

- How to Get Rid of Mushrooms in Your Lawn: A Complete Guide - April 24, 2025

- How to Get Rid of Ground Hornets: A Safe and Effective Guide to Eliminating Nests - April 24, 2025

- How to Get Rid of German Roaches Fast: DIY Methods for Quick Control - April 24, 2025