Welcome to the fundamentals of construction productivity enhancement! This guide will delve into the core concepts, techniques, and strategies to optimize your construction operations and achieve greater efficiency. From understanding the principles of lean construction and embracing technology to optimizing workforce productivity and streamlining supply chain management, we’ll cover the key pillars of productivity enhancement in construction. Whether you’re a seasoned professional or new to the industry, this guide will provide valuable insights to help you unlock the full potential of your construction projects and drive success.

Key Takeaways:

- Measure site productivity based on labor hours, material usage, and output volume.

- Use DfMA (Design for Manufacturing and Assembly) to streamline design and construction processes.

- Implement value engineering to optimize design and reduce costs.

- Standardize and modularize design elements for increased efficiency.

- Plan site layouts for efficient material handling and worker movement.

- Coordinate resources and minimize delays through site deployment planning.

- Ensure timely communication and collaboration with site coordination.

- Integrate technology to improve coordination and data management.

- Implement continuous improvement initiatives to identify and address productivity bottlenecks.

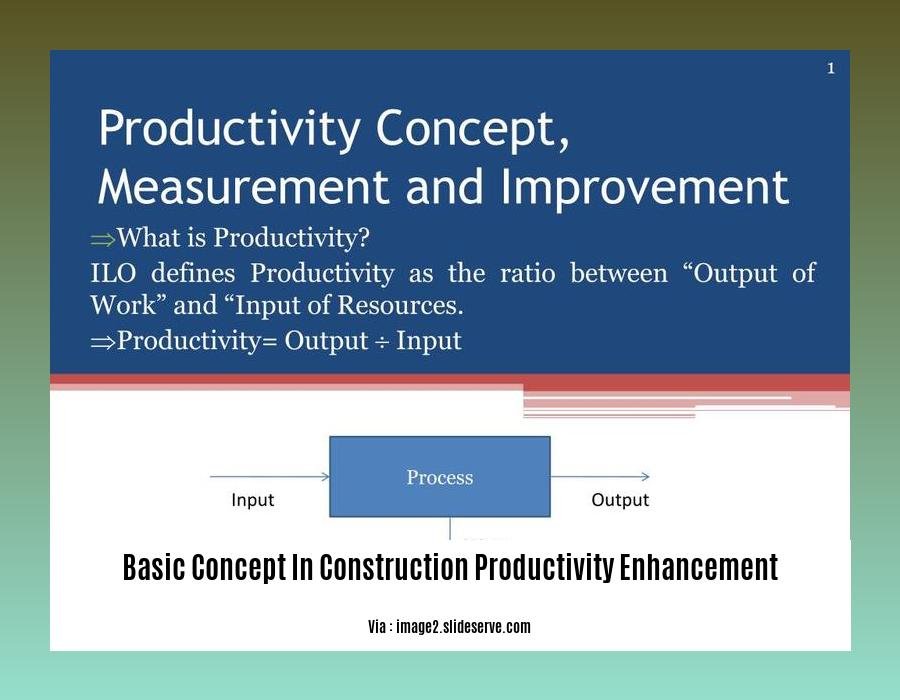

Basic Concepts in Construction Productivity Enhancement

Boosting productivity in construction is crucial for maximizing efficiency, reducing costs, and meeting project deadlines. Start by:

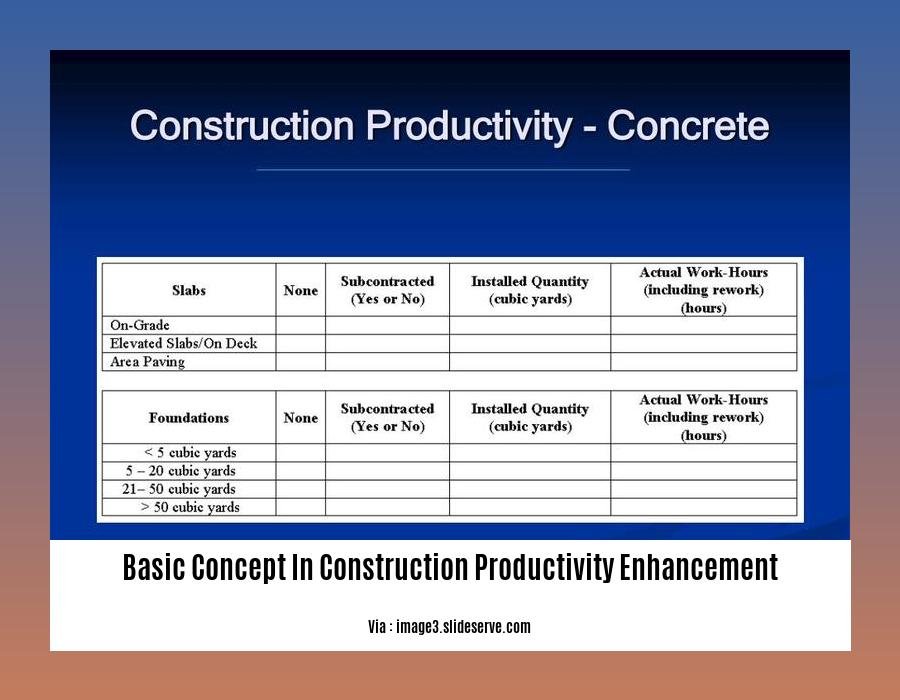

1. Measuring Site Productivity:

Calculate how efficiently your crew utilizes labor, materials, and equipment. This data helps identify areas for improvement.

2. Design for Manufacturing and Assembly (DfMA):

Use prefabricated components and standardized modules to simplify design and reduce on-site work. This streamlines processes and increases efficiency.

3. Value Engineering:

Optimize design by eliminating unnecessary costs and improving functionality. This ensures your projects are both cost-effective and productive.

4. Site Layout Optimization:

Plan your site to minimize material handling and worker movement. Efficient site layout improves productivity and ensures a smoother workflow.

5. Site Deployment Planning:

Coordinate resources and minimize delays by carefully planning the deployment of equipment, materials, and personnel.

6. Continuous Improvement:

Constantly monitor productivity and identify areas for improvement. Implement changes and track their effectiveness to enhance productivity over time.

7. Technology Integration:

Use construction management software, laser scanners, and drones to improve coordination, data management, and decision-making. Technology can significantly boost productivity.

By implementing these basic concepts, you can lay the foundation for significant productivity enhancements in your construction projects.

To get an in-depth understanding of 5 Marla house construction costs in Pakistan in 2023, click here.

To learn about the intricate details of balcony construction, click here.

For a comprehensive overview of basic construction companies, click here.

To decode the acronym “BBM” in the construction industry, click here.

To unravel the meaning of “BBS” in construction, click here.

To grasp the concept of beams in construction, click here.

Workforce Optimization in Construction

When it comes to enhancing construction productivity, Workforce Optimization in Construction plays a pivotal role. It involves leveraging strategies that maximize the efficiency and effectiveness of your workforce, leading to improved project outcomes.

Key Takeaways:

- Efficient Resource Management: Ensure optimal utilization of equipment and labor to minimize downtime and boost productivity.

- Measuring Workforce Productivity: Implement metrics to track and assess labor and equipment performance, allowing you to identify areas for improvement.

- Enhancing Workforce Quality: Improve workforce efficiency through strategic site layout, enhanced coordination, and proactive inspection planning.

Practical Steps for Workforce Optimization:

- Plan Site Layout for Efficiency: Designate dedicated work areas, minimize material handling distances, and optimize equipment placement to reduce congestion and improve task flow.

- Emphasize Site Coordination: Establish clear communication channels, coordinate activities between different trades, and promote teamwork to minimize delays and rework.

- Pre-Plan for Inspections: Schedule inspections early, involve relevant stakeholders, and provide necessary information to avoid rework and expedite project progress.

- Invest in Workforce Training: Provide opportunities for continuous learning and skill development to upskill your workforce and enhance their productivity.

- Implement Lean Construction Principles: Apply lean principles to eliminate waste, reduce bottlenecks, and streamline construction processes.

Benefits of Workforce Optimization:

- Improved project efficiency and reduced timelines

- Enhanced productivity and cost savings

- Increased collaboration and teamwork

- Improved employee satisfaction and retention

Relevant URL Sources

- ScienceDirect

- BCA Academy

Supply Chain Management in Construction

Supply Chain Management (SCM) in construction involves coordinating production and resources by integrating all primary parties involved in construction. Implementing SCM in construction enhances industrialization, improves coordination, and optimizes resource allocation, ultimately leading to increased productivity.

How to improve construction productivity through SCM

- Plan for End-to-End Integration: Establish a seamless flow of information and materials throughout the supply chain, connecting all stakeholders from design to delivery.

- Achieve “Economies of Repetition”: By standardizing designs and processes, you can reduce waste, minimize errors, and improve efficiency.

- Adopt Digital Technologies: Utilize software, sensors, and other digital tools to automate tasks, improve communication, and gain real-time insights.

Types of SCM in Construction

- Lean SCM: This approach focuses on eliminating waste and inefficiencies, particularly in the lower tiers of the supply chain.

- Resilient SCM: This framework emphasizes agility and flexibility, enabling the supply chain to adapt to disruptions and maintain continuity.

Key Takeaways:

- SCM coordinates production and resources in construction, involving all primary parties and integrating construction information.

- Lean SCM optimizes the lower tiers of the supply chain to eliminate waste and inefficiencies.

- Resilient SCM enhances supply chain resilience through dynamic capabilities.

- End-to-end integration, “economies of repetition,” and digital technology adoption are crucial for improving productivity through SCM.

Relevant URL Sources:

- Construction Supply Chain Management: A Systematic Literature Review

- Lean Supply Chain Management in Construction

Continuous Improvement and Innovation in Construction

Key Takeaways:

- Continuous improvement: Identify and eliminate constraints, enhance processes (Lean Construction).

- Stakeholder involvement: Engage all project participants for construction success.

- Gemba walks: Observe on-site to detect and address productivity issues.

- Waste reduction: Eliminate unnecessary activities and expenses (Lean principles).

- Productivity improvements: Resolve disruptions and maintain enhancements over time.

Continuous improvement and innovation are essential for construction productivity enhancement. Embracing the principles of Lean Construction enables us to identify and eliminate constraints that hinder efficiency. Regular Gemba walks provide valuable insights into on-site operations, helping us pinpoint areas for improvement. By engaging all stakeholders, we create a collaborative environment that fosters innovation and problem-solving.

Additionally, waste reduction is paramount to optimizing productivity. Lean principles guide us in eliminating unnecessary activities and expenses that drain resources. Through continuous monitoring and evaluation, we identify specific disruptions and implement solutions to maintain improvements over time.

Citation:

- Improving Construction Productivity by Integrating the Lean Concept

- Improving construction productivity

FAQ

Q1: What are the key factors that affect construction productivity?

Q2: How can DfMA (Design for Manufacturing and Assembly) help improve construction productivity?

Q3: What are the different strategies for enhancing construction productivity during the planning, design, and construction stages?

Q4: How does technology integration contribute to improving construction productivity?

Q5: What are the challenges and opportunities in implementing productivity enhancement initiatives in construction?

- White Kitchen With Butcher Block Countertops: A Warm, Inviting Design - January 4, 2026

- Marble Countertops Prices: What Impacts the Overall Cost to Install? - January 3, 2026

- Marble Countertops Cost: What Factors Impact the Total Price? - January 2, 2026