Dive into the essential guide to binding wire in construction. As a crucial component, binding wire ensures structural integrity, safety, and efficiency on construction sites. Learn the types, properties, and best practices for its application, empowering you to make informed decisions and achieve optimal results. [Essential Guide to Binding Wire in Construction] will equip you with the knowledge and skills to harness the power of binding wire in your construction projects.

Key Takeaways:

- Purpose: Binding rebars to ensure structural stability

- Material: Annealed steel wire for flexibility and strength

- Types: Variety of gauges (16-22), materials, and surface treatments

- Quality factors: Spacing, diameter, type, gauge, and tying method

- Importance: Securing rebars prevents displacement and maintains structural integrity

Binding Wire in Construction

What is Binding Wire?

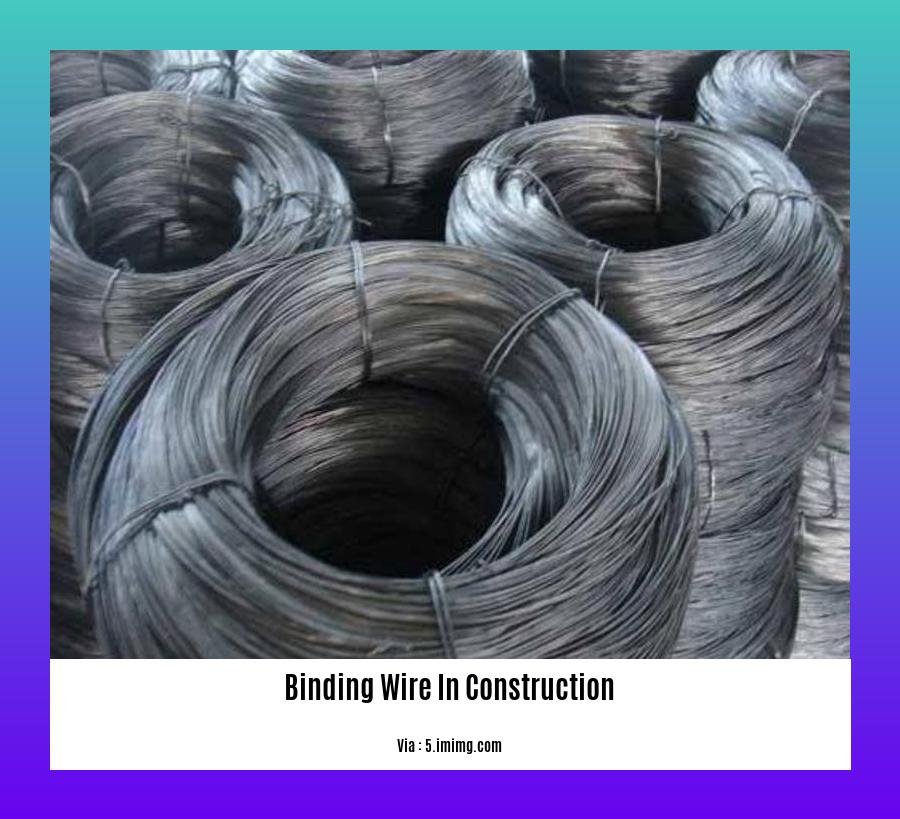

Binding wire in construction is an annealed steel wire used to tie together rebars to maintain structural integrity. Its flexibility and tensile strength make it ideal for this purpose.

Types of Binding Wire

Binding wires come in various gauges (16-22), coatings (galvanized, PVC), and surface treatments (plain, twisted). The type used depends on the material being tied and the surface conditions.

Importance of Binding Wire

Properly tying rebars with binding wire in construction is crucial for several reasons:

- Prevents displacement of rebars

- Maintains structural integrity

- Ensures proper spacing and diameter of rebars

- Allows for uniform concrete placement

Quality Factors for Binding Wire

The quality of binding wire in construction is determined by several factors:

| Factor | Description |

|---|---|

| Spacing | Distance between ties |

| Diameter | Thickness of the wire |

| Type | Plain, twisted, coated |

| Gauge | Thickness of the wire (16 being the thickest) |

| Tying Method | How the wire is tied |

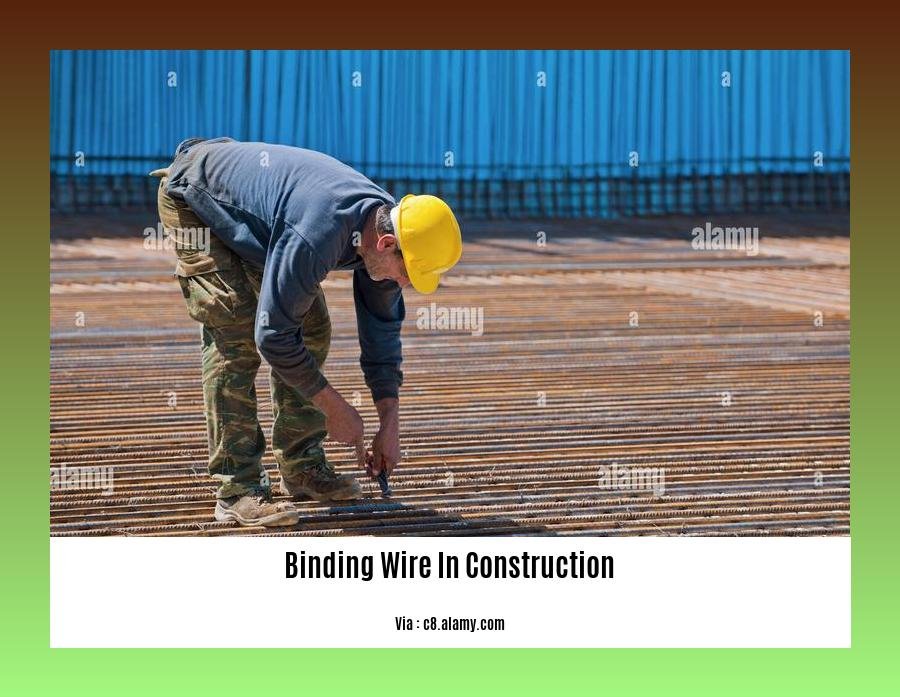

How to Use Binding Wire

Step 1: Preparation

- Wear gloves and safety glasses.

- Cut the binding wire in construction to the desired length.

- Bend one end of the wire into a hook.

Step 2: Tying

- Wrap the hooked end of the wire around one rebar.

- Bring the other end of the wire over the top of the other rebar.

- Wrap the wire around the second rebar and then back over the first rebar.

- Twist the ends of the wire together tightly.

Tips

- Use wire cutters or pliers to cut and twist the wire.

- Tie rebars at regular intervals and in accordance with building codes.

- Inspect ties regularly to ensure they are secure.

If you toil away in the sweltering heat, you can defeat the heat by using the best cooling products for construction workers. Cool down instantly on the job site, and bring a best heated lunch box for construction workers for a warm meal on a cold day. You can even stay safe with a sturdy best iron rod for construction. Here are more details about bitumen used in road construction, and gypsum used in construction. Discover hi beam construction methods for a higher level of reinforcement and durability.

Step-by-Step Guide to Binding Wire Installation

Binding wire plays a crucial role in construction projects, ensuring structural integrity and safety. Whether binding rebars, tying electrical wires, or securing temporary structures, binding wire offers a cost-effective and versatile solution.

Key Takeaways:

- Binding wire strengthens and stabilizes structures by securely connecting components.

- Available in various gauges and coatings, binding wire can withstand different environmental conditions.

- Proper selection and installation techniques are essential for optimal performance and safety.

Step-by-Step Installation Guide:

- Choose the Right Wire:

- Consider the gauge (thickness) and coating (e.g., galvanized, PVC) based on the application.

-

For example, thicker wire (16 gauge) is ideal for heavy-duty applications like rebar tying.

-

Prepare the Materials:

- Cut the binding wire to the desired length, leaving enough slack for twisting.

-

Bend one end of the wire into a hook for easy handling.

-

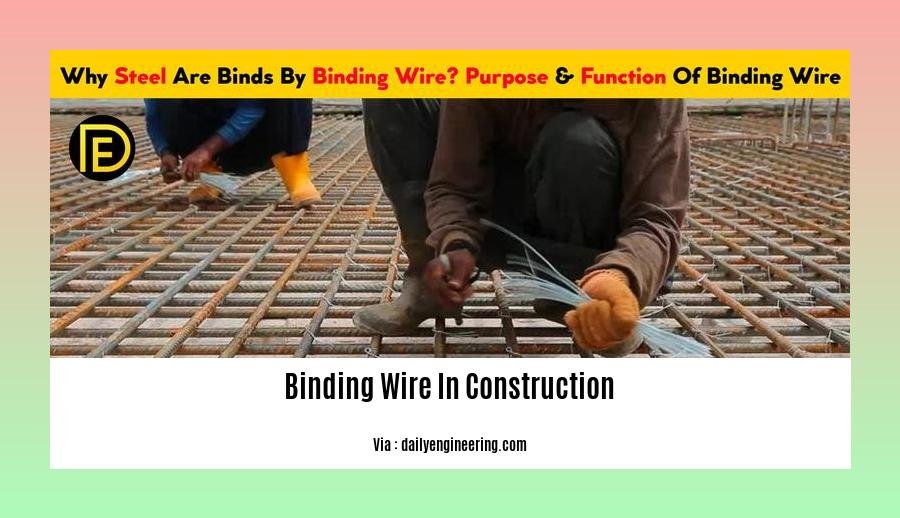

Wrap and Twist:

- Wrap the wire around the components to be secured, creating an overlap of several inches.

-

Use wire cutters or pliers to tightly twist the wire ends together, ensuring a secure connection.

-

Double the Tie:

- For added stability, create a second tie by wrapping the wire around the first tie and twisting again.

Tips:

- Use safety gear (gloves, glasses) when handling binding wire.

- Wear gloves to protect hands from sharp wire edges.

- Regularly inspect binding wire ties to ensure they are secure and free from rust or damage.

Applications:

- Rebar tying

- Electrical wire binding

- Temporary structure assembly

- Landscaping and trellising

Additional Resources:

- How Do You Bind with Wire? | Binding101

- How Do I Bind a Document Using Wire-O Binding? | MyBinding

Troubleshooting Common Binding Wire Issues

When it comes to construction, binding wire is a crucial component. It ensures the structural integrity and safety of any construction project. While it might seem like a simple material, it’s important to understand the common issues that can arise when using binding wire.

Key Takeaways:

- Improper selection of binding wire can lead to inadequate strength or corrosion.

- Correct quantity estimation is essential to prevent wastage or insufficient binding.

- Troubleshooting common binding wire issues involves assessing the cause and implementing appropriate solutions.

Identifying and Resolving Binding Wire Issues

Recognizing and addressing common binding wire issues is essential for successful construction projects. Here are some troubleshooting tips:

- Problem: Wire breakage or slippage.

- Cause: Using wire with insufficient strength or using loose ties.

-

Solution: Select the proper wire gauge for the load and ensure tight tying.

-

Problem: Wire corrosion.

- Cause: Using uncoated wire in corrosive environments.

-

Solution: Use galvanized or other corrosion-resistant coated wire.

-

Problem: Insufficient binding.

- Cause: Not enough binding wire or improper spacing of ties.

-

Solution: Follow building codes for spacing and quantity of wire required.

-

Problem: Difficulty in tying wire.

- Cause: Using dull wire cutters or pliers.

-

Solution: Keep wire cutters and pliers sharp and well-maintained.

-

Problem: Sharp wire ends.

- Cause: Improper cutting or bending.

- Solution: Cut and bend the wire safely using appropriate tools and wear gloves.

Understanding binding wire issues and taking preventive measures can save time, money, and ensure the longevity of construction projects.

Citations:

– Binding Wire in Civil Construction: Uses and Specifications

– The Importance of Binding Wire in Construction

Safety Precautions for Handling and Using Binding Wire

Key Takeaways:

- Wear the right gear: Protect yourself with gloves and eye protection.

- Follow safety regulations: Adhere to OSHA and electrical safety standards.

- Store wire properly: Keep it dry, protected, and away from sources of heat.

- Use the right wire type: Not all binding wires are created equal. Choose the one suitable for your project.

- Cut wire with care: Use wire cutters to avoid sharp or uneven ends.

- Tying Techniques: Proper tying techniques ensure wire effectiveness.

- Inspect regularly: Secure tying prevents loose rebars that can compromise safety.

- Dispose of wire responsibly: Don’t leave it lying around, and recycle it whenever possible.

Handling Binding Wire:

- Wear gloves: Protect your hands from cuts and abrasions.

- Store properly: Keep wire dry and protected to prevent corrosion.

- Inspect regularly: Before using wire, check for damage or corrosion.

Using Binding Wire:

- Cut with care: Use sharp wire cutters to cut binding wire cleanly and avoid leaving sharp edges.

- Tie securely: Wrap the wire around the rebars, pulling firmly but not so tight that the wire breaks.

- Inspect ties: After tightening the wire, check for any loose or damaged ties that need attention.

Citations:

- Importance of Binding Wire in Construction

- Binding Wire in Civil Construction: Uses and Specifications

FAQ

Q1: What is the purpose of binding wire in construction?

A1: Binding wire is crucial for tying reinforcing bars (rebar) together to maintain structural integrity, preventing displacement and ensuring the structure’s stability.

Q2: What is the recommended spacing and diameter of binding wire?

A2: The spacing and diameter of binding wire depend on the rebar diameter, structural member type, and document thickness. Specific guidelines and tables are available to determine the appropriate specifications.

Q3: What factors influence the quantity of binding wire required?

A3: Factors such as bar diameter, spacing, structural member type, and binding wire gauge and type influence the quantity of binding wire needed. A rule of thumb suggests 1% of the total weight of reinforcement steel.

Q4: What safety precautions should be taken when handling binding wire?

A4: Wear appropriate personal protective equipment (PPE) like gloves and eye protection. Follow OSHA regulations and electrical safety standards when handling or cutting binding wire.

Q5: How to select the right type of binding wire for construction?

A5: Consider material properties (steel, aluminum, copper) and intended use. The wrong type can lead to issues like inadequate strength or corrosion. Match the binding wire type and gauge to the rebar diameter, spacing, and structural part type.

– The Role of Binding Wire in Construction: A Comprehensive Guide for Professionals

Delve into the world of construction as we explore [- The Role of Binding Wire in Construction: A Comprehensive Guide for Professionals]. In this insightful guide, discover the significance of binding wire in reinforcing concrete structures and ensuring their durability. Learn about wire gauges, tensile strengths, industry standards, and safety measures to elevate your construction practices.

Key Takeaways:

- Binding wire is essential for tying rebar joints, ensuring structural integrity.

- Binding wire is made from annealed steel to enhance its flexibility.

- Wire quality is determined by factors like rebar spacing, diameter, gauge, and tying technique.

- Common binding wire gauges range from 16 to 22, with 18 gauge being widely used.

Binding Wire in Construction

Understanding Binding Wire

Binding wire, an indispensable material in construction, plays a critical role in ensuring the structural integrity of concrete structures. It securely ties rebars at joints, creating a strong and durable foundation. The steel used for binding wire undergoes annealing, enhancing its flexibility and ease of tying.

Factors Affecting Binding Wire Quality

Several factors influence the quality of binding wire in construction:

- Spacing between rebars: Closer spacing requires thicker wire.

- Diameter: The thickness of the wire, measured in millimeters.

- Gauge: A measure of the wire’s thickness, with lower gauge numbers indicating thicker wire (18 gauge is common).

- Tying method: Different methods, such as manual tying or mechanical tying, impact wire selection.

Gauge and Strength

The gauge of the wire determines its tensile strength, which is crucial for ensuring structural stability. Typically, binding wire gauges range from 16 to 22, with 18 gauge being widely used.

Best Practices for Using Binding Wire

- Ensure the wire is of the appropriate gauge and tensile strength for the application.

- Keep wire spools dry to prevent rust and ensure smooth tying.

- Wear gloves when handling binding wire to protect hands from sharp edges.

- Dispose of used wire responsibly to avoid injuries and environmental hazards.

Looking for a way to stay cool and comfortable while working hard on construction sites? Check out the best cooling products designed specifically for construction workers. If you need to warm up your lunch, then you need the best heated lunch box for construction workers.

For your construction projects, you need to use the best iron rod for construction. Ensuring the road’s durability, learn more about the bitumen used in road construction.

If you’re looking for a versatile material for your construction projects, read about the gypsum used in construction. Finally, if you need a construction method that offers strength and durability, check out hi-beam construction.

Tensile Strength and Gauge Considerations

Tensile strength and gauge are crucial factors to consider when selecting binding wire for construction projects. Tensile strength measures the wire’s resistance to breaking under tension, while gauge refers to the thickness of the wire.

Importance of Tensile Strength

High tensile strength is crucial for ensuring the integrity of concrete structures. It prevents the wire from snapping or stretching under load, ensuring that the rebar remains firmly in place. Insufficient tensile strength can lead to premature failure or collapse.

Gauge Considerations

The gauge of binding wire determines its thickness. Thinner wire, such as 22 gauge, is more flexible and easier to handle, but has lower tensile strength. Thicker wire, such as 18 gauge, is more robust and has higher tensile strength but can be stiffer and less pliable.

Recommendations

- Choose a gauge appropriate for the load: Higher loads require thicker wire with higher tensile strength.

- Refer to industry standards: Standards such as ASTM A82 and IS 280 provide guidelines on tensile strength and gauge specifications.

- Avoid using rusty or damaged wire: Rust weakens the wire, reducing its tensile strength and compromising the structural integrity.

- Inspect the wire regularly: Check for any signs of corrosion or damage and replace any defective wire promptly.

Key Takeaways:

- Tensile strength and gauge are critical considerations for binding wire in construction.

- Tensile strength ensures the wire can withstand load without breaking.

- Gauge determines the thickness and handling ease of the wire.

- Match the wire’s gauge and tensile strength to the specific project requirements.

- Regular inspection and maintenance are essential to maintain the integrity of the wire.

Sources:

- ASTM A82: Standard Specification for Steel Wire, Cold-Drawn for Mechanical Springs

- IS 280(2006): Mild Steel and Medium Tensile Steel Bars and Rods – Specification

Codes, Standards, and Safety Practices in Binding Wire Application

When it comes to Codes, Standards, and Safety Practices in construction, binding wire plays a crucial role. To ensure the durability and safety of structures, adhering to these guidelines is essential. Here’s a quick guide to help you understand the key regulations and best practices:

Materials and Specifications:

- Use binding wire that meets the specifications outlined in IS 280(2006). This standard specifies the tensile properties, chemical composition, and tolerance limits for binding wire.

Gauge and Strength:

- The gauge of the binding wire indicates its thickness and tensile strength. 18 gauge is commonly used for most applications.

Quantity Estimation:

- Approximately 1% of the total weight of reinforcement steel should be allocated for binding wire.

Tying Techniques:

- Tie rebars securely using proper techniques to prevent movement or displacement. The double-loop tie is a widely accepted method.

Safety Precautions:

- Wear gloves to prevent cuts and abrasions when handling binding wire.

- Keep the wire dry to avoid rust and ensure its effectiveness.

- Dispose of used wire responsibly to prevent injury or environmental hazards.

Key Takeaways:

- Ensure binding wire complies with IS 280(2006) standards for quality and safety.

- Choose the appropriate gauge for the required tensile strength.

- Estimate the binding wire quantity based on the total weight of reinforcement steel.

- Follow proper tying techniques to secure rebars effectively.

- Adhere to safety precautions to minimize risks and maintain a safe work environment.

Relevant URL Sources:

- Binding Wire Consumption As Per Is Code | PDF

- Binding wire required for 1 ton Steel as per IS code

Quality Control and Inspection Techniques

Inspections are crucial for Quality Control and Inspection Techniques in construction. Scrutinize rebar placement, spacing, and ensure the correct gauge and type of wire is used. Examine the concrete mix for consistency, pour depth, and curing time. Regular checks prevent defects that compromise the structure’s integrity.

Key Takeaways:

- Quality Control: Plan procedures, use inspection checklists, address deviations, and document findings.

- Visual Inspection: Check rebar location, wire condition, concrete mix, and curing status.

- Measurement and Testing: Verify dimensions, clearances, and concrete strength through testing.

- Documentation and Reporting: Record inspection results, photographs, and any necessary corrective actions.

Relevant URL Sources:

- Construction Quality Assurance & Quality Control

- QC in Construction: How Builders Manage Quality Control

FAQ

Q1: What specifications should be considered when selecting binding wire?

A1: When selecting binding wire, it is crucial to consider factors such as wire gauge, tensile strength, spacing between rebars, diameter, and the specific tying method to be employed.

Q2: What is the most commonly used gauge for binding wire?

A2: In construction, 18 gauge binding wire is widely used due to its optimal balance of strength, flexibility, and ease of handling.

Q3: How can binding wire contribute to structural integrity?

A3: Binding wire plays a vital role in maintaining structural integrity by securely tying rebars at joints in concrete structures. This prevents displacement, ensures proper load distribution, and enhances the overall stability of the structure.

Q4: What safety precautions should be taken when using binding wire?

A4: When handling binding wire, it is important to wear protective gloves to prevent cuts and abrasions. Additionally, proper disposal of used wire is crucial to avoid injuries and maintain a clean work environment.

Q5: What factors determine the quantity of binding wire required for a construction project?

A5: The quantity of binding wire required is typically estimated as a percentage of the total weight of reinforcement steel used in the project. Factors such as the complexity of the structure, rebar spacing, and wire gauge influence the specific quantity needed.

- NYT Connections Answer: Hedgehog, Pineapple, Cactus The Spiky Things Explained - April 20, 2025

- How to Clean a Wool Carpet: A Comprehensive Guide - April 20, 2025

- How to Clean a Pleather Couch: A Complete Guide - April 20, 2025