– Bitumen Used in Road Construction: A Comprehensive Guide to Its Properties and Applications –

Key Takeaways:

- Bitumen’s low production cost makes it an economical choice.

- It adapts to temperature and load changes due to its thermoplastic and viscoelastic properties.

- Bitumen provides water resistance and durability, suitable for flexible road construction.

- The 60/70 grade bitumen is commonly used for its versatility in varying temperatures.

Bitumen: A Critical Component in Road Construction

What is Bitumen?

Bitumen is a naturally occurring or refined viscous hydrocarbon. It’s a black, sticky substance found in crude oil. When crude oil is processed in refineries, bitumen is separated as a byproduct.

Properties and Characteristics:

- Water resistance: Bitumen is highly impermeable to water, making it ideal for road construction.

- Durability: Bitumen roads can withstand heavy traffic loads and extreme weather conditions.

- Flexibility: Bitumen is thermoplastic and viscoelastic, allowing it to adapt to changing temperatures and load conditions.

Types of Bitumen Used in Road Construction:

The most common grade of bitumen used in road construction is 60/70 grade, also known as paving-grade bitumen. It’s suitable for a wide range of temperatures and has a good balance of properties.

Benefits of Using Bitumen in Road Construction:

- Cost-effective: Bitumen is a relatively inexpensive material compared to other road construction materials.

- Durability: Bitumen roads can last for decades with proper maintenance.

- Flexibility: Bitumen roads can adapt to changing temperatures and load conditions, reducing the risk of cracking.

- Noise reduction: Bitumen roads are quieter than concrete roads, reducing noise pollution.

Applications of Bitumen:

Bitumen is used in various road construction applications, including:

- Asphalt pavements: Bitumen is the primary binder used in asphalt pavements, providing strength, flexibility, and water resistance.

- Asphalt overlays: Bitumen overlays are used to improve the performance of existing asphalt pavements or convert existing pavements into asphalt pavements.

- Crack sealing: Bitumen is used as a sealant to fill cracks in asphalt pavements, preventing water infiltration and extending pavement life.

- Pothole repair: Bitumen is used to fill potholes, restoring the pavement’s integrity and safety.

Environmental Considerations:

Bitumen is a non-renewable resource. However, it can be recycled and reused in road construction, reducing its environmental impact. Additionally, bitumen is biodegradable and does not pose significant environmental hazards.

If you work in the construction industry, you need the right gear to stay cool and comfortable on the job. Discover the best cooling products for construction workers.

Packing a healthy lunch is essential for any construction worker. Check out the best heated lunch box for construction workers.

Iron rods are an essential part of any construction project. Find the best iron rod for construction.

Binding wire is a versatile material used in a variety of construction applications. Learn more about binding wire in construction.

Gypsum is a common material used in construction. Explore the uses of gypsum in construction.

Hi beam construction is a type of construction that uses high-strength steel beams. Learn more about hi beam construction.

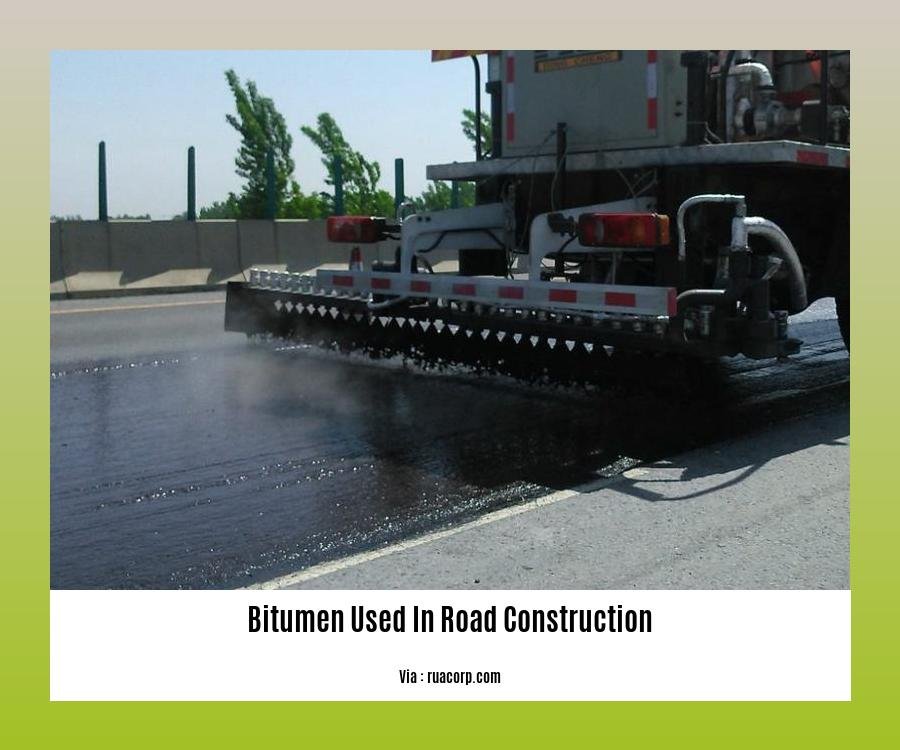

Bitumen Application Methods in Road Construction

Asphalt and bitumen, with their exceptional properties and adaptability, are the most common materials to construct durable and secure roads. The process of applying bitumen as a binder in road construction is critical. Let’s dive into the methods used to incorporate bitumen into the road structure:

Hot Mix Asphalt (HMA)

The most prevalent method, involves heating bitumen and blending it with aggregates (crushed stone, gravel, or sand). This pliable mixture is then spread and compacted, forming a stable road surface. HMA provides excellent durability, skid resistance and waterproofing capabilities.

Cold Mix Asphalt (CMA)

When temperature constraints limit the use of HMA, CMA is a viable alternative. It employs bitumen emulsions or cutback bitumen, mixed with aggregates at ambient temperatures. CMA is convenient, cost-effective, and can be used for patching, overlays, and minor road repairs.

Key Takeaways:

- Bitumen, a versatile binder, plays a crucial role in road construction.

- Bitumen Application Methods in Road Construction are tailored to specific project requirements and environmental conditions.

- HMA, with its hot mixing process, offers superior durability and performance.

- CMA provides cost-effective solutions for low-temperature applications and minor repairs.

Relevant URL Sources:

[1] Bitumen Road Construction | Processes and Materials

[2] Exploring the Role of Bitumen in Road Construction: Benefits and Applications

Factors Affecting Bitumen Performance in Roads

Bitumen, a significant component in road construction, plays a crucial role in ensuring durability and longevity. Understanding the factors influencing its performance is essential for effective road design and maintenance.

Factors Affecting Bitumen’s Performance

- Exposure to oxygen and temperature changes: Oxidation and thermal stress can degrade bitumen, leading to premature aging and cracking.

- Poor quality aggregates: Weak aggregate bonds with bitumen can result in surface wear and stripping.

- Weak binding between aggregates and bitumen: Insufficient adhesion can compromise pavement strength and durability.

- High void content and permeability: Voids and cracks allow water and air to penetrate, causing bitumen degradation and weakening the pavement.

Why Durability Matters

Durable pavements not only extend road life but also:

- Reduce maintenance costs

- Improve traffic safety

- Enhance user comfort

Key Takeaways:

- Exposure: Oxygen and temperature fluctuations can deteriorate bitumen.

- Aggregates: Poor quality aggregates can compromise bitumen adhesion.

- Binding: Strong aggregate-bitumen bonding is crucial for pavement strength.

- Void content: Minimizing voids and cracks prevents water and air infiltration.

Sources:

- Durability of Bituminous Pavements and Factors Affecting it

- Why is Bitumen Used in Road Construction? Properties and Advantages

Advancements and Innovations in Bitumen Technologies

Key Takeaways:

- Alternative Bitumen: Natural bitumen and bio-bitumen offer sustainable options to reduce dependence on conventional bitumen.

- Polymer Modification: Enhancing properties like durability and temperature resistance through polymer additives.

- Bio-based Bitumen: A promising renewable source derived from biomass, promoting environmental friendliness.

Exploring Alternative Bitumen Sources

The traditional reliance on crude oil-derived bitumen has spurred the search for alternative sources due to concerns about depletion and sustainability. Natural bitumen reserves offer a viable option, with their abundance and unique properties. Researchers are also exploring bio-bitumen, derived from plant biomass, as a renewable and eco-friendly alternative.

Polymer Modification: Enhancing Performance

Polymer modification has emerged as a cutting-edge technique to enhance the properties of bitumen. By introducing polymers, engineers can improve durability, resistance to temperature fluctuations, and overall performance of bitumen-based pavements. This innovation extends the lifespan of roads and reduces maintenance costs.

Sustainable Future with Bio-bitumen

The push for sustainability in road construction has led to the development of bio-bitumen. This innovative material is derived from plant-based oils and offers significant environmental benefits. Bio-bitumen is biodegradable, reduces greenhouse gas emissions, and promotes the use of renewable resources.

Relevant Sources:

- Next-Generation Bitumen: Paving the Way for Sustainable Road Construction

- Bio-bitumen: A Sustainable Alternative for Road Construction

FAQ

Q1: What are the advantages of using bitumen in road construction?

A1: Bitumen’s waterproof, adhesive, and viscous properties make it an ideal material for road construction. It fills cracks, prevents further damage, provides skid resistance, and protects underlying layers.

Q2: What is the most common grade of bitumen used in road construction?

A2: The most common grade of bitumen used in road construction is 60/70 grade, known as paving-grade bitumen. It is suitable for a wide range of temperatures.

Q3: What factors affect the durability of bituminous pavements?

A3: Factors affecting durability include exposure to oxygen and temperature changes, poor quality aggregates, weak binding between aggregates and bitumen, and high void content and permeability.

Q4: What are the advancements in bitumen technologies?

A4: Advancements include next-generation bitumen such as bio-bitumen from biomass and polymer-modified bitumen with enhanced durability and temperature resistance.

Q5: What are the environmental and health concerns associated with conventional bitumen?

A5: Conventional bitumen’s high PAH content and presence of hydrogen sulfide pose environmental and health risks.

– The Use of Bitumen in Road Construction: A Comprehensive Perspective

In the realm of road construction, bitumen, a versatile and essential material, plays a pivotal role. Its unique properties and adaptability have made it the preferred choice for paving roads worldwide. In this comprehensive article titled [- The Use of Bitumen in Road Construction: A Comprehensive Perspective], we delve into the intricacies of bitumen, exploring its types, applications, and the cutting-edge techniques employed in its implementation.

Key Takeaways:

- Economical Option: Bitumen is a cost-effective material to produce as it’s a byproduct of crude oil refining.

- Versatile Material: Its unique properties make bitumen suitable for various road construction applications.

- Byproduct of Crude Oil: Bitumen is obtained when crude oil is processed to extract other products like petrol and diesel.

- Flexible Road Construction: Bitumen is widely used for flexible roads because it binds well and resists deformation.

Bitumen Used in Road Construction

Bitumen, commonly known as asphalt, is a dark, viscous material derived from crude oil. Its unique properties make it an ideal material for use in road construction.

Properties of Bitumen

- Thermoplastic: Softens when heated and hardens when cooled.

- Viscoelastic: Flows like a liquid under stress but behaves like an elastic solid when force is removed.

- Water-resistant: Impermeable to water, protecting against moisture damage.

Why is Bitumen Used in Road Construction?

- Economical: A by-product of crude oil refining, making its production cost-effective.

- Durable: Withstands heavy traffic loads, resists cracking and deformation, and has a long lifespan.

- Versatile: Can be customized to meet specific road conditions and traffic requirements by adjusting its hardness and composition.

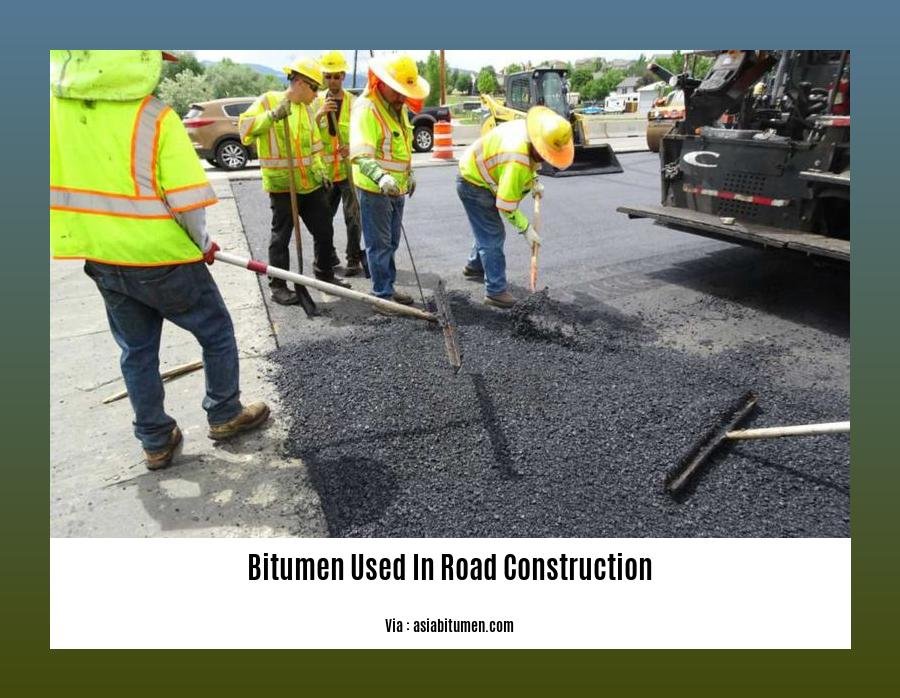

Steps in Using Bitumen for Road Construction

- Site Preparation: Clear the area, grade the surface, and compact the subgrade.

- Laying the Binder Course: Apply a layer of bitumen mixed with aggregates (gravel, sand, etc.) to bind the base together.

- Compacting the Binder Course: Roll the binder course to ensure proper density and adhesion.

- Laying the Surface Course: Apply a final layer of bitumen mixed with finer aggregates to provide a smooth driving surface.

- Compacting the Surface Course: Roll the surface course to achieve the desired smoothness and compaction.

Advantages of Using Bitumen for Road Construction

- Durability: Creates long-lasting, heavy-duty roads that can withstand stress and wear.

- Water-resistance: Prevents water penetration, reducing road damage and extending its lifespan.

- Cost-effective: Relatively low production costs compared to other paving materials.

Disadvantages of Using Bitumen for Road Construction

- Temperature Sensitivity: Can become soft and sticky in hot weather, potentially causing road warping.

- Emissions: Produces fumes during application, requiring proper ventilation.

- Maintenance: May require periodic repairs and resurfacing due to aging and wear.

Prepare your construction crew for the heat with our selection of the best cooling products for construction workers.

Packed lunches just got better! Discover the best heated lunch box for construction workers and keep meals warm and satisfying.

Ensure robust and durable structures with the best iron rod for construction.

Binding wire in construction plays a crucial role; explore our guide to understand its significance.

Delve into the world of gypsum used in construction, its properties, and applications, to enhance your construction knowledge.

Achieve structural excellence with the innovative techniques of hi-beam construction.

Safety Precautions in Bitumen Road Construction

Key Takeaways:

- Always prioritize safety during bitumen road construction projects.

- Use personal protective equipment (PPE) like gloves, masks, and safety glasses.

- Ensure proper ventilation and avoid prolonged exposure to bitumen fumes.

- Store and handle bitumen safely to prevent spills and accidents.

- Follow established guidelines and regulations for bitumen handling and disposal.

PPE and Ventilation:

When working with bitumen, wear appropriate PPE to protect yourself from harmful substances and vapors. This includes:

- Gloves to prevent skin contact

- Masks to avoid inhaling fumes

- Safety glasses to protect your eyes from splashes

It’s crucial to ensure adequate ventilation during bitumen application to dissipate fumes and prevent respiratory issues.

Storage and Handling:

Store bitumen safely in designated areas, away from heat sources and ignition points. Follow proper handling procedures to prevent spills, such as using insulated containers and avoiding dragging hoses on the ground.

Emergency Preparedness:

Be prepared for emergencies by having a fire extinguisher and other safety equipment readily available. In case of spills or contact with bitumen, immediately clean the affected area and seek medical attention if necessary.

Compliance and Regulation:

Follow established guidelines and regulations for bitumen handling and disposal. These may vary depending on your location, so check with local authorities for specific requirements.

Citations:

- OSHA Bitumen Safety Standards

- National Asphalt Pavement Association: Safety Best Practices

Types of Bitumen Used in Road Construction

In road construction, bitumen is the glue that holds it all together. Its versatile properties make it an essential component for creating durable and safe roads.

Key Takeaways:

- Cutback Bitumen: Heated to reduce viscosity for easier application

- Bitumen Emulsion: Liquid containing dispersed bitumen, stabilized with additives

- Bituminous Primers: Absorbed into road surfaces to improve adhesion

- Modified Bitumen: Enhanced with additives to improve specific properties

Common Types of Bitumen

Cutback Bitumen:

Enhanced with heat to make it less viscous, cutback bitumen is ideal for applications that require easy application, such as sealing cracks and potholes.

Bitumen Emulsion:

This liquid form of bitumen contains water and additives to stabilize it. It is commonly used in cold applications, such as surface dressing.

Bituminous Primers:

Primers are applied to road surfaces to improve the adhesion of bitumen to the underlying layers. They are typically made from bitumen dissolved in distillate oil.

Modified Bitumen:

Additives are mixed into bitumen to enhance specific properties, such as durability, flexibility, or temperature resistance. These modifications are useful in extreme weather conditions or heavy traffic areas.

Sources:

Advantages of using bitumen in road construction

Bitumen is a sticky, black substance that is used to bind together the aggregate materials in asphalt paving. It is a by-product of crude oil refining, and it is one of the most important materials used in road construction.

There are many advantages of using bitumen in road construction, including:

Key Takeaways:

- Durability: Bitumen is a very durable material that can withstand heavy traffic loads and harsh weather conditions. Asphalt pavements made with bitumen can last for many years with proper maintenance.

- Water resistance: Bitumen is waterproof, which helps to protect roads from damage caused by water penetration.

- Flexibility: Bitumen is a flexible material that can conform to the shape of the road surface. This helps to prevent cracking and potholes.

- Cost-effective: Bitumen is a relatively inexpensive material, which makes it a cost-effective option for road construction.

In addition to these advantages, bitumen is also a very versatile material that can be used in a variety of road construction applications, including:

- Asphalt paving: Bitumen is the primary binder in asphalt paving, which is the most common type of road surface in the world.

- Crack sealing: Bitumen can be used to seal cracks in asphalt pavements, preventing them from spreading and causing further damage.

- Chip sealing: Bitumen can be used to apply a thin layer of aggregate to the surface of an asphalt pavement, improving its skid resistance and durability.

Bitumen is a valuable material that plays an important role in road construction. Its durability, water resistance, flexibility, and cost-effectiveness make it an ideal choice for a variety of road construction applications.

Sources:

FAQ

Q1: What is the main advantage of using bitumen in road construction?

A1: Bitumen offers several advantages, including its cost-effectiveness, versatility, and ability to withstand heavy traffic loads and variable weather conditions.

Q2: How does bitumen improve the durability of roads?

A2: Bitumen’s flexibility and resistance to deformation allow it to adapt to temperature changes and traffic loads, minimizing the formation of cracks and potholes. Its water resistance also protects the road structure from moisture infiltration and damage.

Q3: Is bitumen an environmentally friendly material for road construction?

A3: Bitumen is a by-product of crude oil refining, making its production more sustainable compared to other materials. However, the environmental impact of bitumen depends on the specific source and production methods.

Q4: What are the different types of bitumen used in road construction?

A4: Bitumen is available in various types, including cutback bitumen, bitumen emulsion, bituminous primers, and modified bitumen. Each type has unique properties and applications based on the specific requirements of the road project.

Q5: How can bitumen be used to repair roads?

A5: Bitumen is commonly used to repair cracks and potholes in roads. Its ability to fill and seal these imperfections effectively prevents further damage and extends the lifespan of the road surface.

- White Kitchen With Wood Countertops: A Warm Design - January 7, 2026

- Modern Butcher Block Kitchen: Warmth and Style with White Cabinets - January 6, 2026

- White Cabinets with Butcher Block Countertops: A Kitchen Classic - January 5, 2026