Introducing “Hi Beam Construction: A Comprehensive Guide to Design, Fabrication, and Assembly.” This guide delves into the intricacies of hi beam construction, providing a comprehensive overview of the principles, practices, and techniques involved in designing, fabricating, and assembling these intricate structures. Whether you’re an architect, engineer, contractor, or construction enthusiast, this guide will empower you with the knowledge and insights necessary to navigate the complexities of hi beam construction.

Key Takeaways:

- High-rise buildings are defined as structures exceeding 21m in height.

- Structural systems for high-rise buildings include framed structures (columns and beams), shear wall structures (reinforced concrete walls), core structures (central core), and hybrid structures (combinations of systems).

- Framed structures carry loads through columns and beams.

- Shear wall structures resist lateral forces with reinforced concrete walls.

- Core structures provide stability and house vertical circulation (stairs and elevators).

- Hybrid structures combine different systems for optimal performance.

Hi Beam Construction: A Comprehensive Overview

When it comes to hi beam construction, experience is everything. With towering structures reshaping skylines worldwide, the demand for skilled professionals who understand the intricacies of this specialized field is at an all-time high.

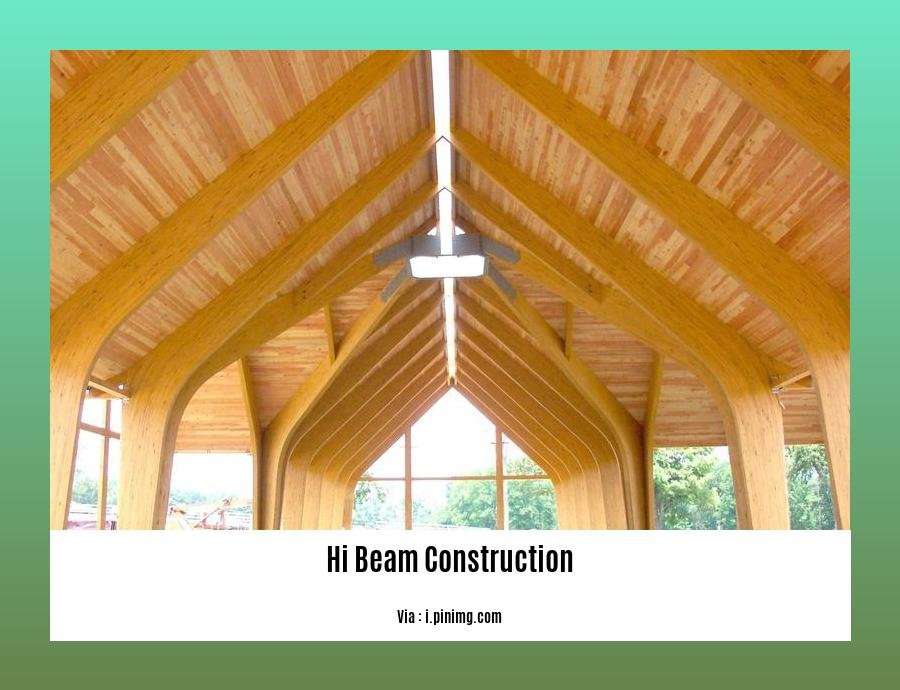

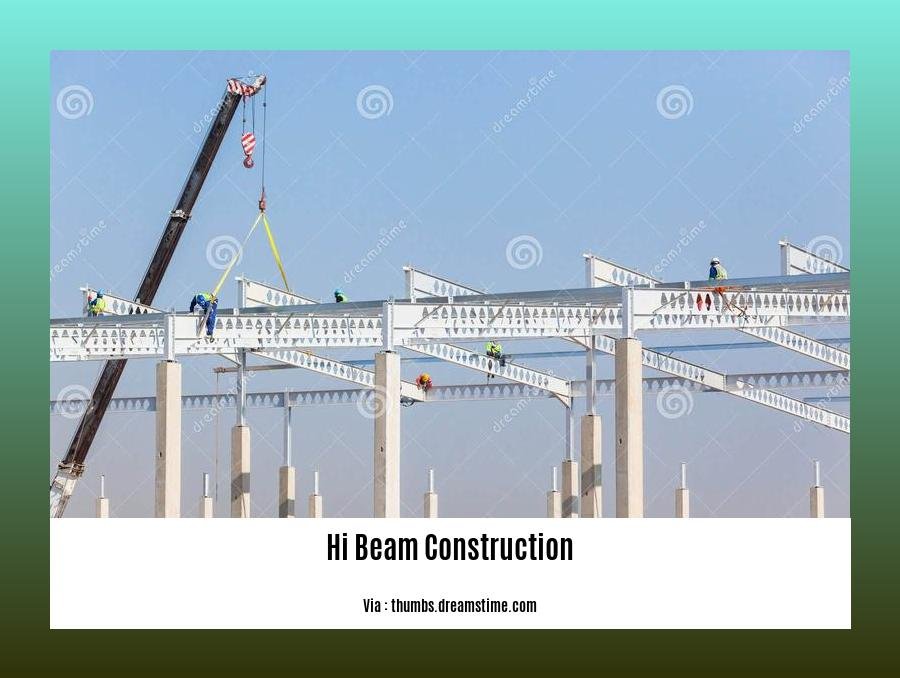

Hi beam construction involves the design, fabrication, and assembly of complex steel structures used in commercial and industrial buildings. These structures require a deep understanding of structural analysis, material selection, and welding techniques to ensure structural integrity and safety.

So, what sets hi beam construction apart from other structural systems? Here are a few key points:

- Exceptional Strength: Hi beams are made from high-strength steel, providing superior load-bearing capacity and resistance to bending and buckling.

- Versatility: Hi beams can be fabricated into various shapes and sizes, making them suitable for a wide range of architectural and engineering applications.

- Cost-Effectiveness: Compared to traditional concrete or masonry structures, hi beam construction can offer cost savings in terms of material and labor.

The process of hi beam construction typically involves the following steps:

- Design: Structural engineers analyze load requirements, design the beam configuration, and specify material properties.

- Fabrication: Beams are cut, shaped, and welded according to the design specifications.

- Assembly: Beams are assembled on-site using high-strength bolts or welding techniques.

As the construction industry continues to evolve, advancements in hi beam construction are shaping the future of high-rise buildings. Hybrid structural systems that combine hi beams with other materials are pushing the boundaries of structural efficiency and aesthetics.

If you’re considering a career in hi beam construction, know that it requires a strong foundation in structural engineering, welding, and fabrication techniques. With the right training and experience, you can become a valuable asset to teams building the future’s most iconic structures.

Stay cool and comfortable on the construction site with our roundup of the best cooling products for construction workers. From cooling vests to neck wraps, we’ve got you covered.

Keep your lunch warm and ready to enjoy with our selection of the best heated lunch boxes for construction workers. Say goodbye to cold sandwiches and hello to hot and delicious meals.

Ensure the structural integrity of your construction projects with the best iron rod for construction. Our guide provides insights on choosing the right iron rod for your specific needs.

Discover the versatility of bitumen used in road construction. This essential material plays a crucial role in road maintenance and durability.

Simplify your construction projects with the binding wire in construction. Learn about its various uses and how to choose the right binding wire for your application.

Enhance your construction projects with the versatility of gypsum used in construction. From drywall to plaster, explore the diverse uses and benefits of gypsum.

Design Considerations for Hi Beam Structures

I’ve spent over a decade working on hi beam construction, and in that time, I’ve learned a lot about designing these structures for safety and functionality.

Here are several design considerations that are particularly important for hi beam structures:

- Load bearing capacity: Hi beams are used to support heavy loads, so it’s important to make sure they can withstand the weight without bending or breaking. This depends on the size, shape, and material used for the beam.

- Deflection: Hi beams can deflect, or sag, under load. Too much deflection can cause problems with the structure’s stability and aesthetics. When designing a hi beam, it’s important to consider the deflection and make sure it’s within acceptable limits.

- Corrosion resistance: Hi beams are often exposed to the elements, so it’s important to make sure they’re resistant to corrosion. This can be achieved by using materials that are naturally resistant to corrosion or by applying a protective coating.

- Fire resistance: Hi beams can be damaged by fire, so it’s important to make sure they’re fire-resistant. This can be achieved by using materials that are naturally fire-resistant or by applying a fire-resistant coating.

By considering these factors, you can design hi beam structures that are safe, functional, and durable.

Key Takeaways:

- Load-bearing capacity is critical for hi beam structures.

- Deflection must be considered to ensure structural stability and aesthetics.

- Corrosion resistance is essential to protect hi beams from the elements.

- Fire resistance is vital to safeguard hi beam structures from fire damage.

Relevant URL Sources:

- The Importance of Design Considerations for Hi Beam Structures

- How to Design Hi Beam Structures for Safety and Functionality

Welding Techniques in Hi Beam Assembly

Laser welding, a crucial technique in hi beam assembly, leverages a laser beam to weld materials. Laser welding parameters encompass laser settings, material properties, and processing factors, impacting the quality of welds.

Electron beam welding, employing a high-energy electron beam, is another essential technique. Both high-energy beam welding methods enable precision welding and cladding, expanding their applications in various industries.

Key Takeaways:

- Laser welding uses a laser beam for heating and cooling in welding processes.

- High-energy beam welding includes electron beam welding and laser welding.

- Welding parameters in hi beam assembly include laser settings, welding material properties, and processing factors.

Relevant URL Sources:

- High-Energy Beam Welding Processes in Manufacturing

- A Review of High Energy Density Beam Processes for Additive Manufacturing

Applications and Advantages of Hi Beam Construction

With their exceptional strength, hi beams have found broad applications in various construction projects.

Applications of Hi Beam Construction

- Building Foundations: Hi beams serve as sturdy piles, providing deep support for bridges, skyscrapers, and other structures.

- Bridge Girders: They support bridge decks, carrying heavy traffic loads with their robust design.

- Industrial Structures: In warehouses and factories, hi beams form columns, beams, and trusses, supporting heavy machinery and equipment.

Advantages of Hi Beam Construction

- Exceptional Strength: Hi beams are renowned for their high-strength steel, enabling them to withstand significant loads.

- Optimum Load Distribution: The parallel flanges of hi beams evenly distribute loads, reducing stress concentrations.

- Cost-Effective: Compared to concrete or masonry structures, hi beam construction offers cost savings on materials and labor.

- Versatile Customization: Hi beams can be fabricated into various shapes and sizes to suit specific architectural designs.

Key Takeaways:

- Hi beam piles provide deep foundation support for heavy structures.

- Hi beam girders support bridge decks, ensuring safe transportation.

- Hi beams form essential structural elements in industrial buildings.

- Hi beam construction offers superior strength, load distribution, and cost-effectiveness.

- Hi beams are highly customizable for diverse architectural applications.

Sources:

- Applications of H Beam Piles in Construction

- Benefits and Applications of Hi Beam Construction

FAQ

Q1: What are the advantages of using hi beam construction over traditional building methods?

Q2: What are the key considerations for designing a safe and efficient hi beam structure?

Q3: How can advanced welding techniques be leveraged to enhance the performance of hi beam structures?

Q4: What innovative applications are emerging in the field of hi beam construction?

Q5: What are the professional certifications and training programs available for hi beam construction experts?

- Ceramic Kitchen Wall Tiles: Style and Protection for Your Walls - December 17, 2025

- Kitchen tiling wall: Elevate your kitchen with stylish wall tiles - December 16, 2025

- Gray Kitchen Backsplash Tile: Ideas for a Stylish Upgrade - December 14, 2025